Stirring device with detachable shaft sleeve

A stirring device and detachable technology, which is applied in the field of detachable shaft sleeve stirring devices, can solve the problems of shaft sleeve wear, the bottom cannot be disassembled, and the replacement of the shaft sleeve is cumbersome, etc., so as to ensure stability, improve service life, and reduce friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

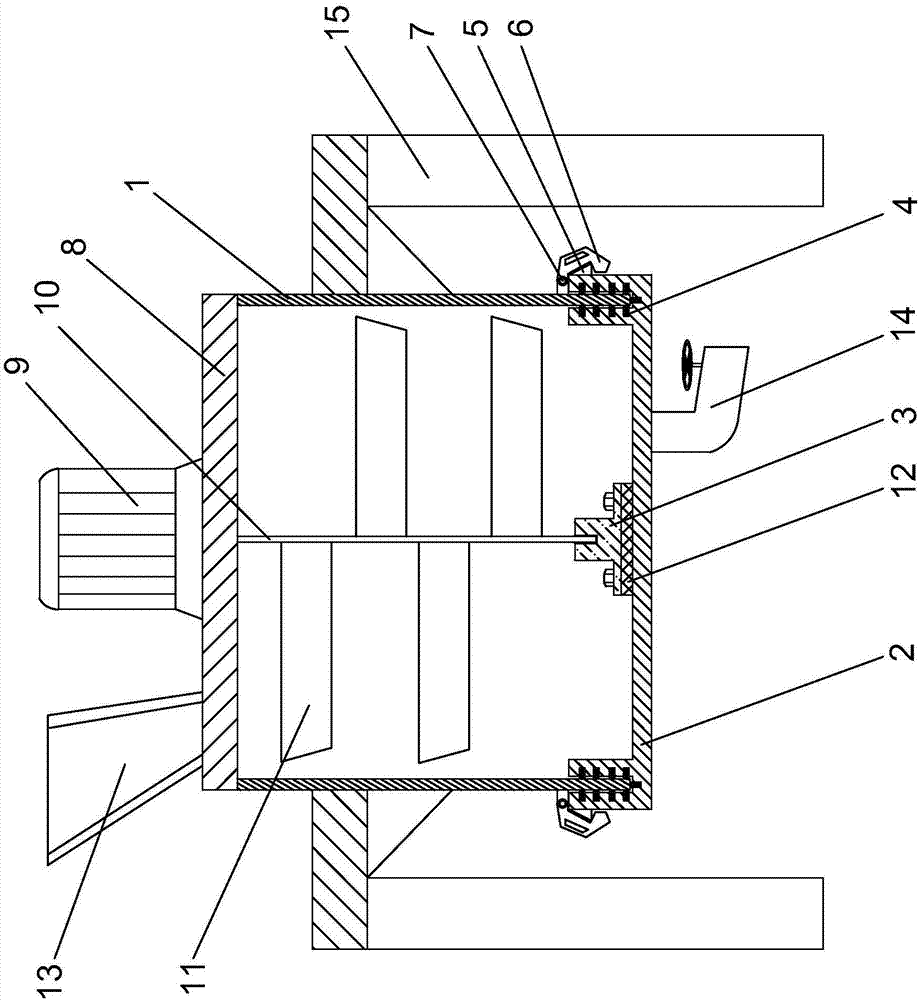

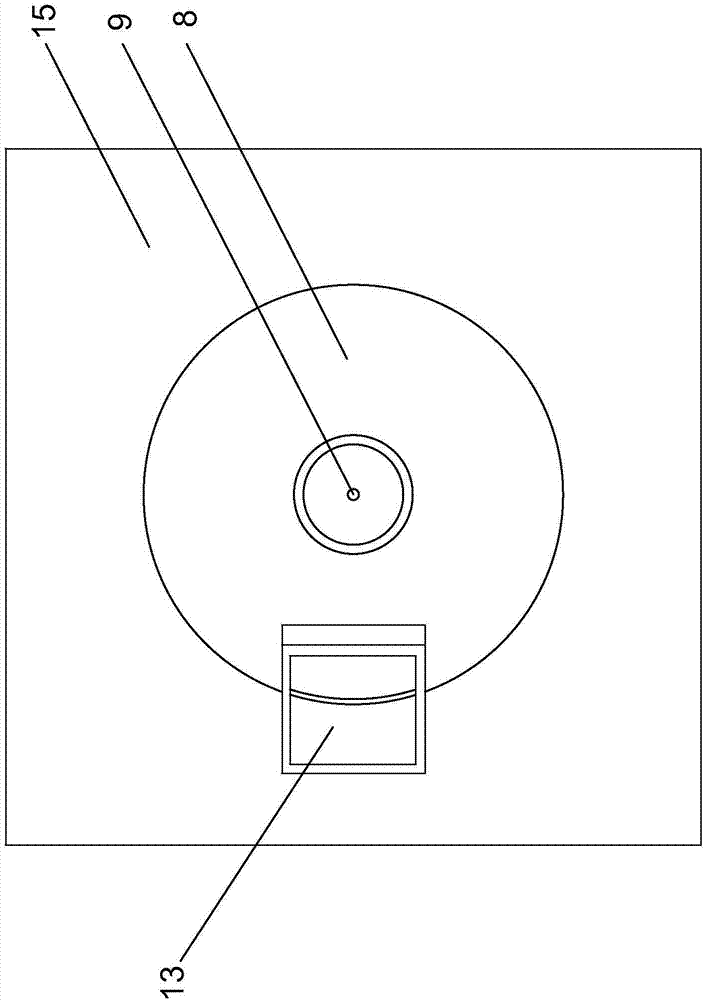

[0011] Such as figure 1 , 2 As shown, the shaft sleeve detachable mixing device of the present invention comprises a mixing tank 1, a base 2, and a shaft sleeve 3. Correspondingly, a plurality of sealing rings 4 are arranged in the groove, and a plurality of blocks 5 are arranged on the outside of the base 2, and the blocks 5 correspond to the fixed handle 6 provided on the outside of the bottom of the mixing bucket 1, and the fixed handle 6 passes through the rotating shaft 7 is connected to the outer wall of the mixing bucket 1, the base 2 is fixed in the bottom of the mixing bucket 1 through the clamping block 5 in the fixed handle 6, the mixing bucket cover 8 is arranged above the mixing bucket 1, and the motor 9 is arranged above the mixing bucket cover 8 , the inside of the mixing tank 1 is provided with a stirring shaft 10 driven by a motor 9, and stirring blades 11 are evenly arranged on the stirring shaft 10, and the bushing 3 is installed on the base 2 inside the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com