Reconfigurable robot end effector assembly

A technology of end effectors and components, applied in the direction of manipulators, circuits, connections, etc., can solve the problems of packaging size, adjustability and weight that are not ideal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

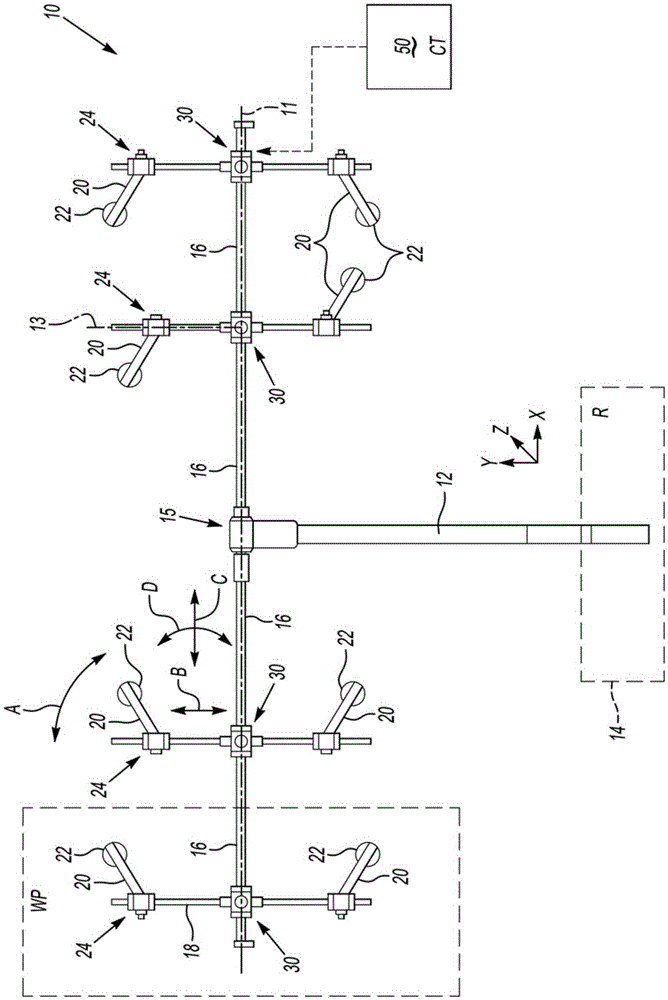

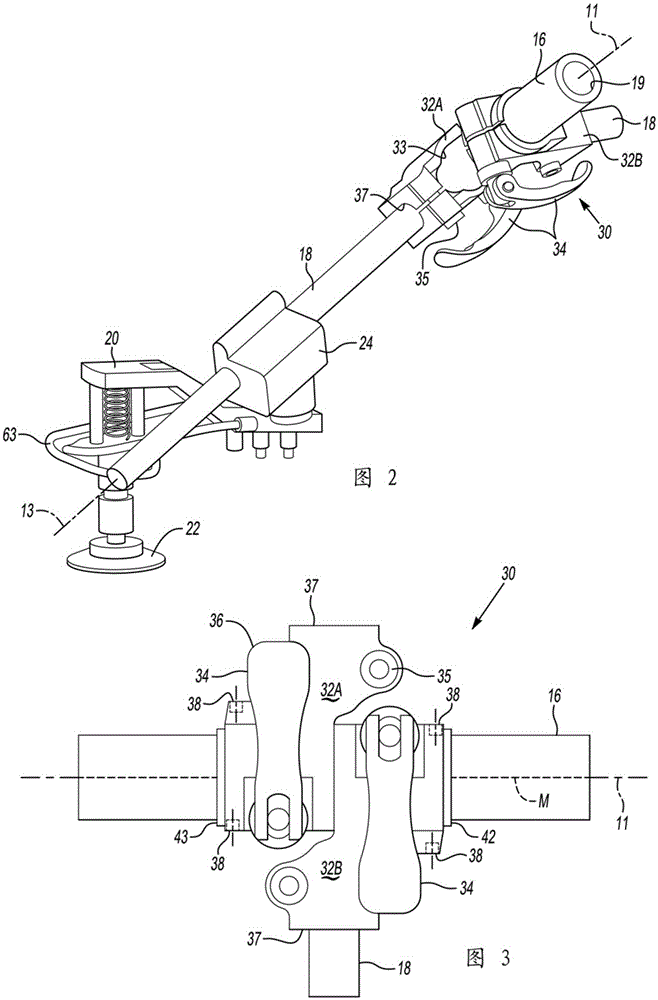

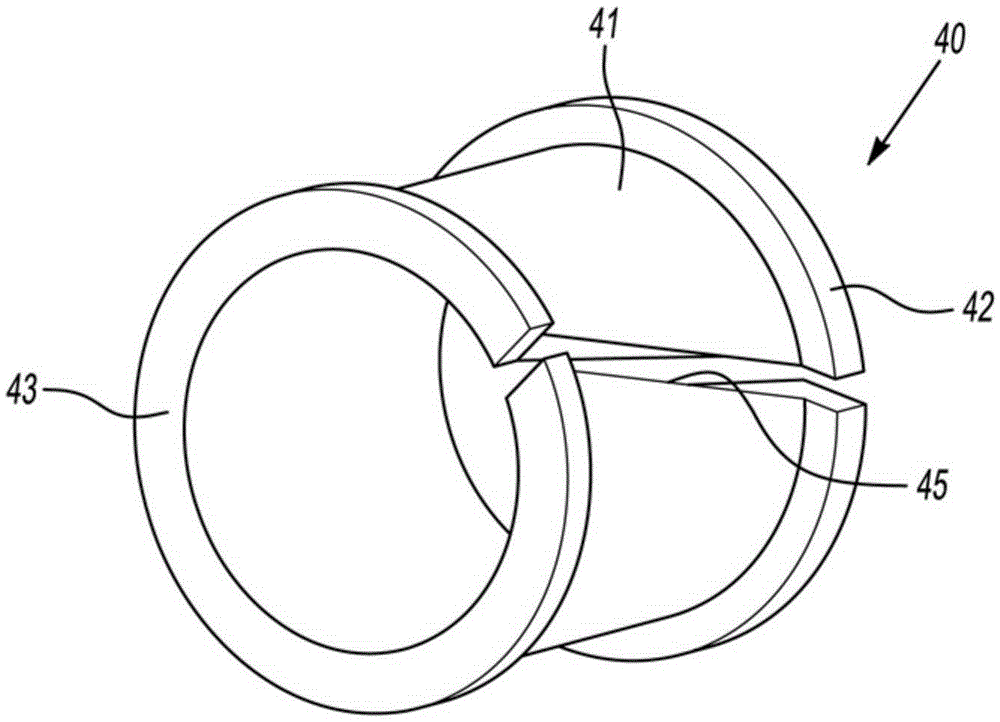

[0015] Referring to the drawings, wherein like reference numerals refer to like parts throughout, a reconfigurable end effector assembly 10 is schematically shown at figure 1 middle. End effector assembly 10 includes a main arm 12 connected via a T-fitting 15 or other suitable connector to a support arm 16 having a longitudinal axis 11 . The arm 16 may have an inner wall 19, such as figure 2 and 4 shown in . The main arm 12 can be positioned anywhere in the Cartesian (xyz) frame of reference (i.e., free space) as desired by the robot (R) 14, such as a multi-axis material handling robot of the type commonly used in manufacturing facilities for logistics purposes . As is well understood in the art, such a robot 14 is programmable, fixed to a stationary or movable base, and configured to position the main arm 12 with respect to the workpiece (WP) as desired.

[0016] The support arm 16 of the end effector assembly 10 extends orthogonally with respect to the main arm 12 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com