Mold and method for forming tilt boss

A technology of convex pillars and molds, which is applied in the field of molds for making oblique convex pillars, to achieve the effect of simplifying mold design and shortening the production process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

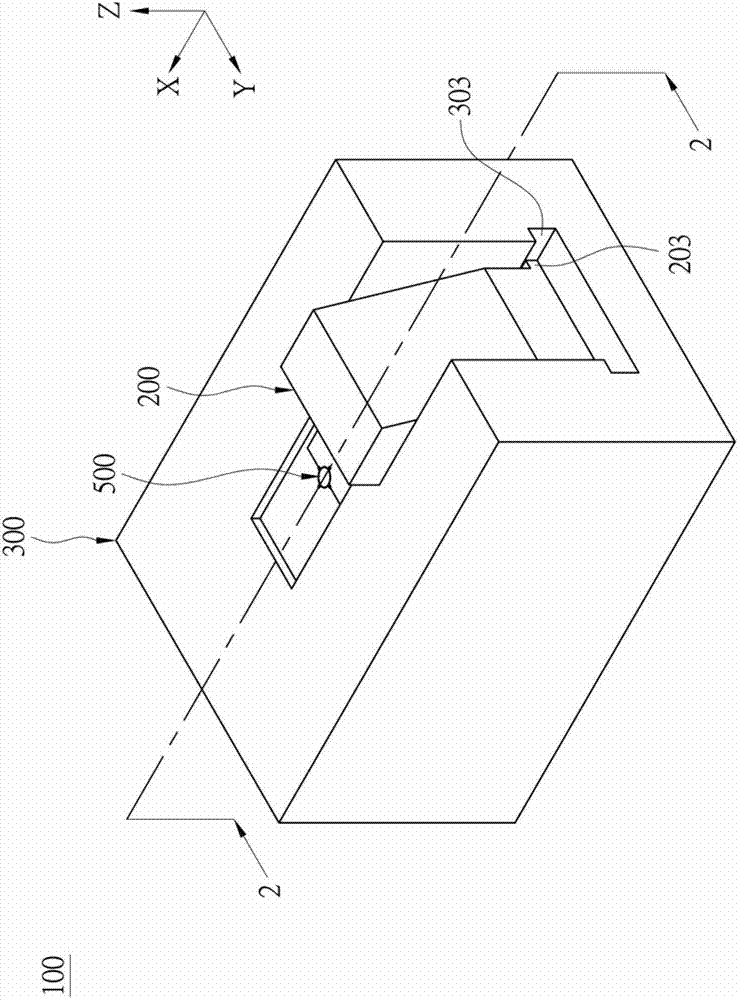

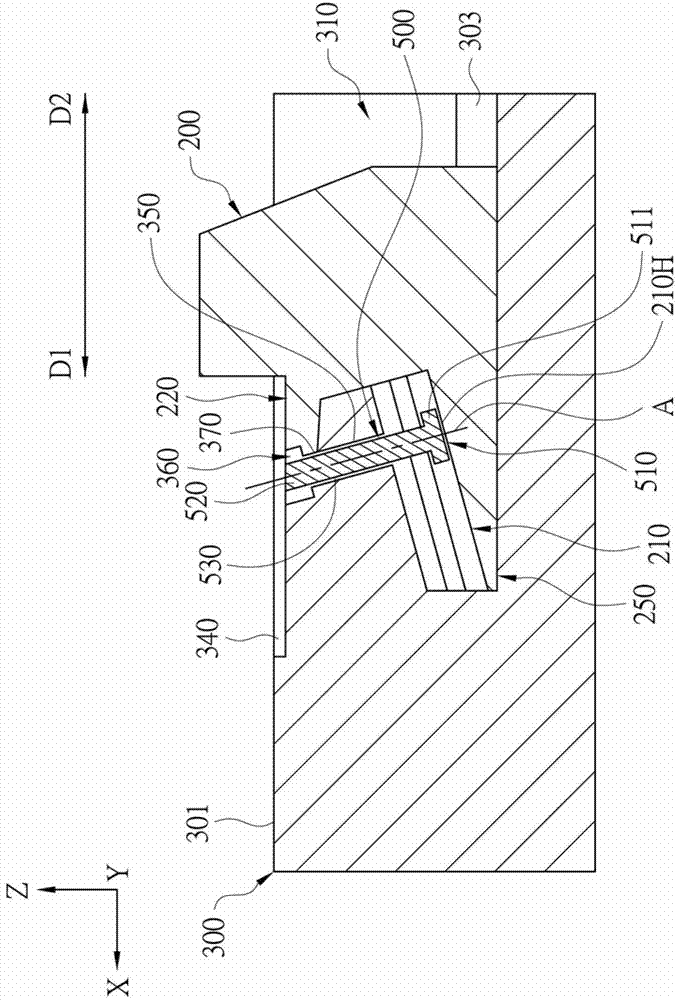

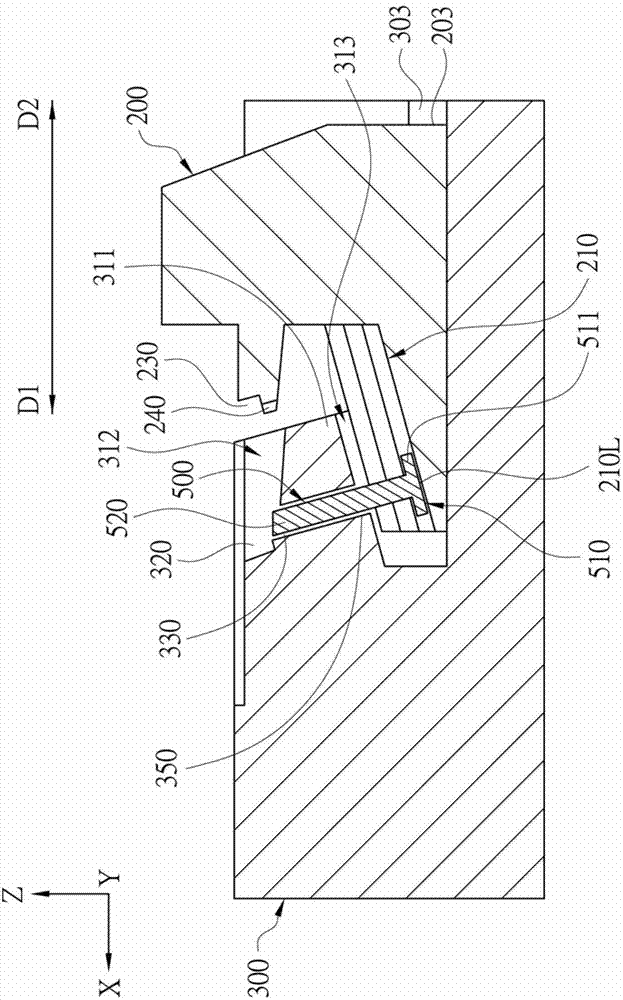

[0075] Various embodiments of the present invention will be disclosed below with accompanying drawings, and for the sake of clarity, many practical details will be described together in the following description. It should be understood, however, that these practical details should not be used to limit the invention. That is, in some embodiments of the invention, these practical details are unnecessary. In addition, for the purpose of simplifying the drawings, some conventional structures and elements will be shown in a simplified and schematic manner in the drawings.

[0076] In view of the obliquely extending characteristic of the oblique protruding post formed in the prior art, the oblique protruding post will be interfered by the mold during demolding and cannot be withdrawn. To this end, the present invention provides a mold and method for forming an oblique convex column, so that the hole-forming pin that cooperates with forming the oblique convex column can immediately...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap