A kind of naphtha catalytic reforming method

A technology for catalytic reforming and naphtha, applied in the field of hydrocarbon conversion, can solve the problems of small scale of the first reactor and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

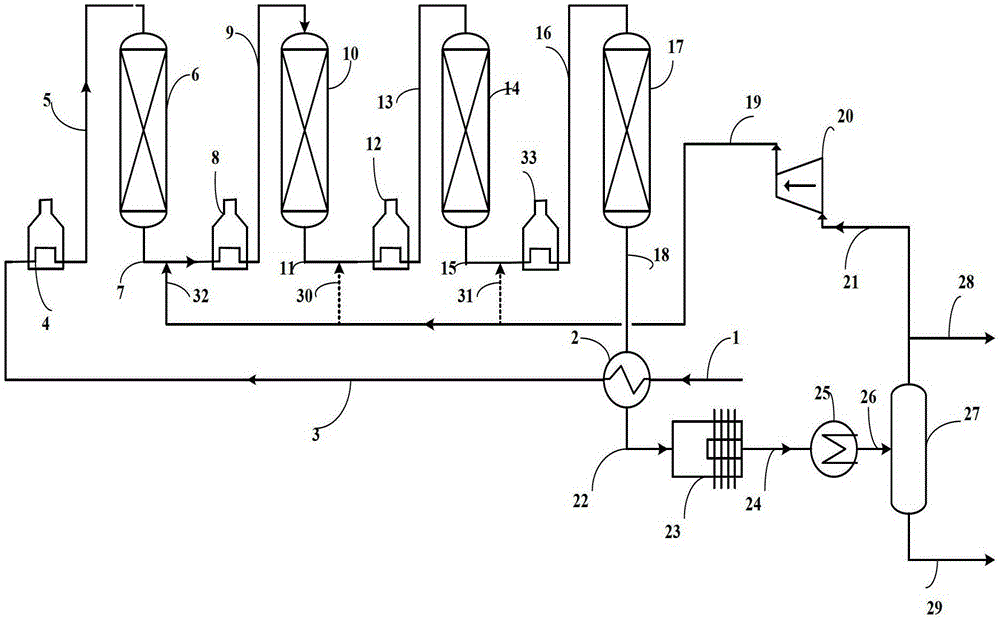

Method used

Image

Examples

example 1

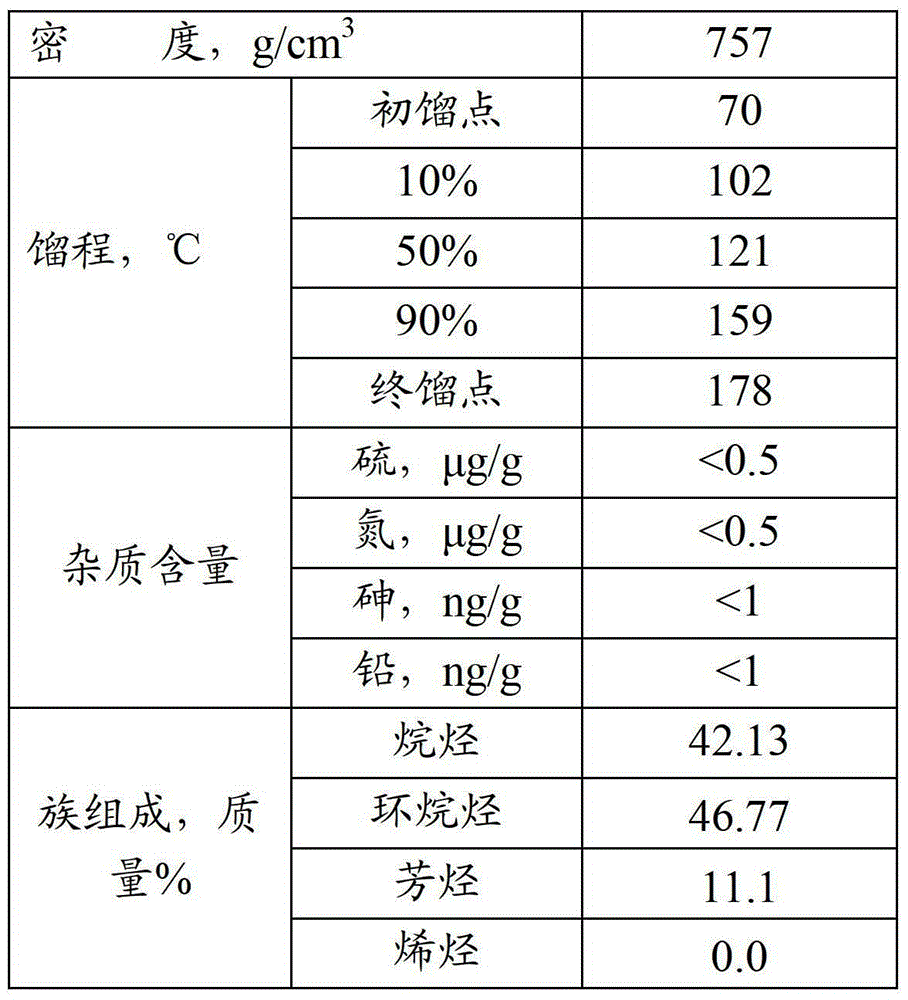

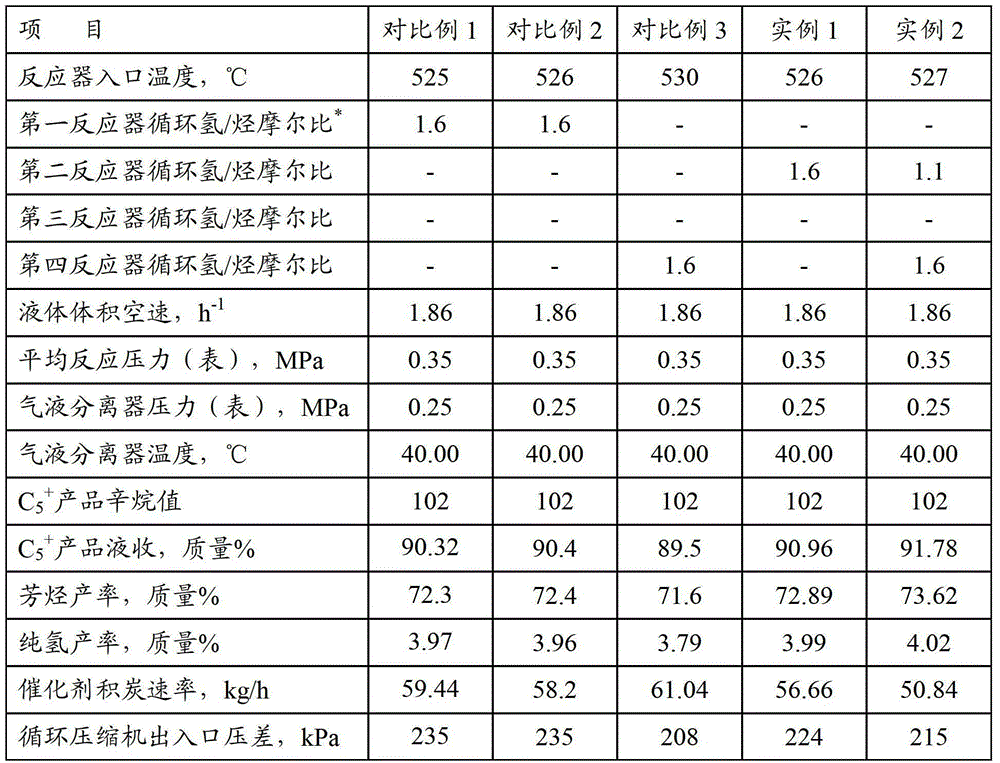

[0027] When the method of the invention is adopted to carry out the continuous reforming reaction of naphtha, the circulating hydrogen from the outlet of the compressor of the continuous reforming device does not enter the first reactor, but all enters the second reactor. The continuous reforming catalyst RC011 produced by Hunan Jianchang Catalyst Co., Ltd. was used, which contained 0.28% by mass of Pt and 0.41% by mass of Sn, and the carrier was γ-alumina. The properties of the refined naphtha used are shown in Table 1, and the reaction conditions and results are shown in Table 2.

example 2

[0029] Adopt the method of the present invention to carry out the naphtha continuous reforming reaction, the circulating hydrogen from the compressor outlet of the continuous reforming unit does not enter the first reactor, and is divided into two streams and enters the second reactor and the fourth reactor respectively, wherein 80% by volume The circulating hydrogen of 20% by volume enters the second reactor, and the circulating hydrogen of 20% by volume enters the fourth reactor. Catalyst used and naphtha are all the same as example 1, and reaction conditions and results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com