A countercurrent continuous reforming method

A countercurrent and reforming reaction technology, which is applied in the direction of naphtha catalytic reforming, etc., can solve the problems of inability to convert aromatics and reduce the yield of gasoline components, and achieve the goal of increasing yield and gasoline yield, and reducing the rate of carbon deposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

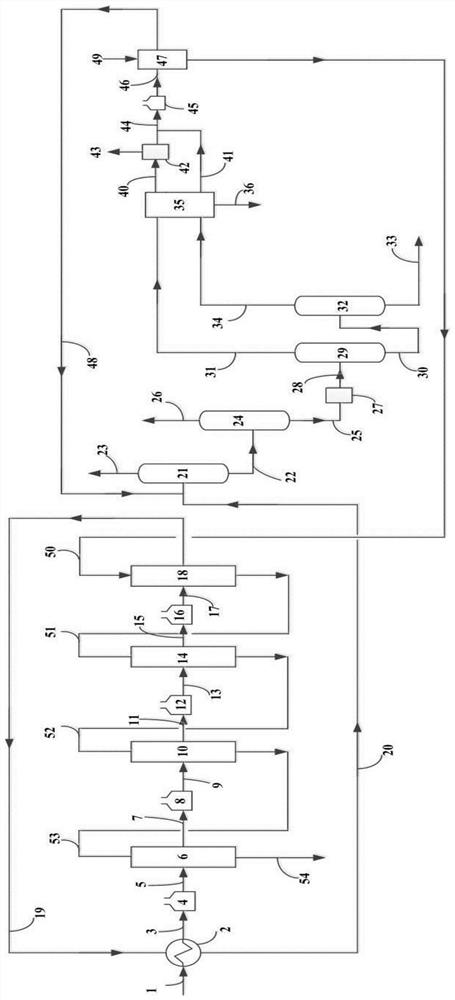

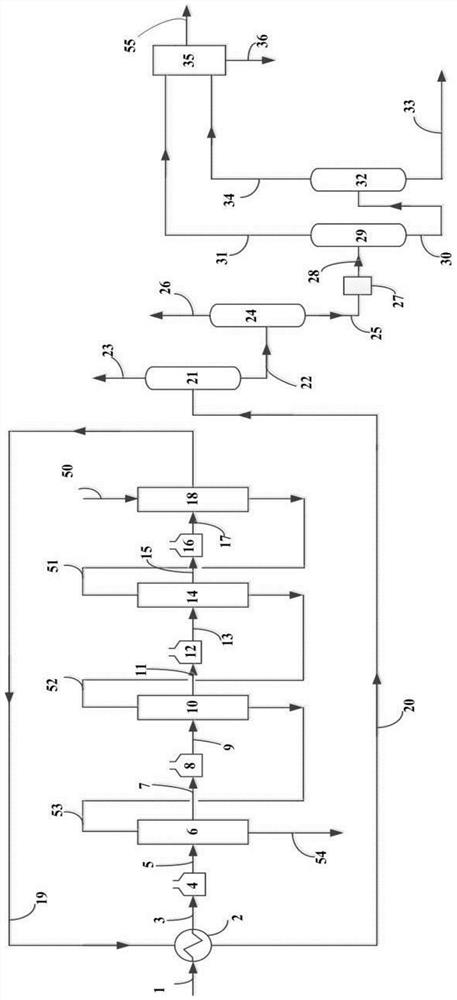

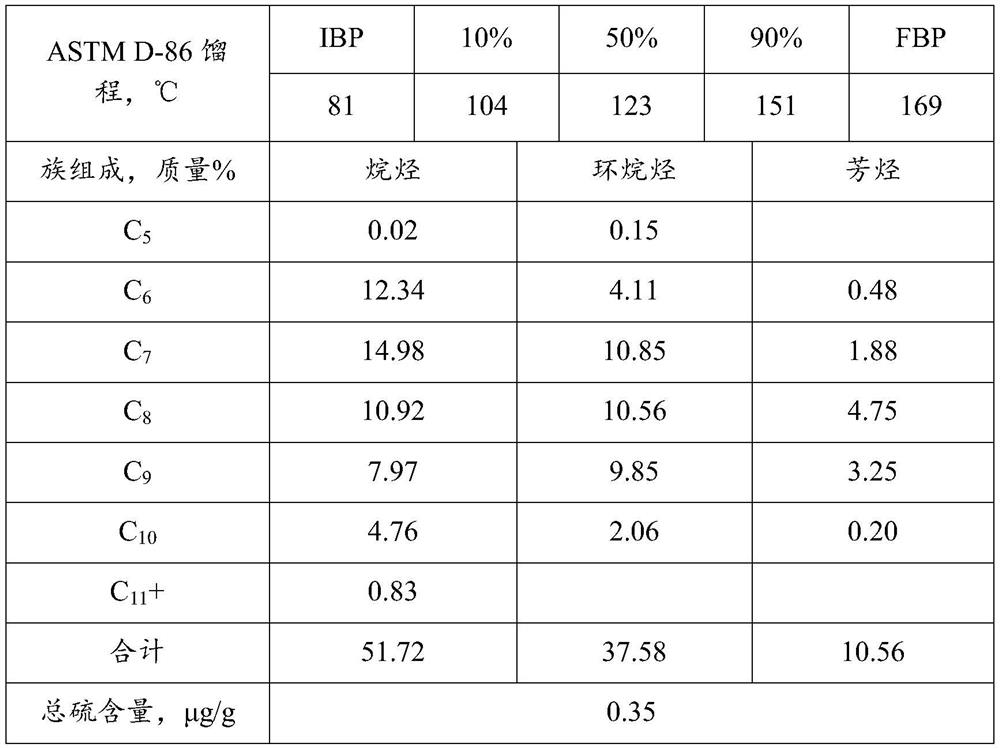

[0041] according to figure 1 The process shown performs countercurrent continuous reforming of naphtha. The reforming catalyst (produced by Hunan Jianchang Petrochemical Co., Ltd., brand RC011) loaded in the first to fourth reactors and the tail reactor is γ-Al 2 o 3 , wherein the Pt content calculated based on the carrier is 0.28% by mass, and the Sn content is 0.31% by mass. Among them, the catalyst loading in the tail reactor accounts for 4.7% by mass of the total loading of the four front reactors, and the loading ratios of catalysts in the first, second, third, and fourth reactors are 15% by mass: 20% by mass: 25% by mass. Mass %: 40 mass %. The properties of the naphtha raw materials used are shown in Table 1, and the C in the reforming reaction product 6 + The de-olefin catalysts used to remove olefins from the generated oil include 47% DOSY molecular sieve, 48.2% sepiolite, 1.0% lanthanum oxide, and 3.8% cerium oxide. The de-olefin reaction conditions are 195°C, 1...

example 2

[0043] Carry out countercurrent continuous reforming of naphtha according to the method of example 1, the difference is to increase the temperature of each reactor, and the main operating conditions and reaction results of the device are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com