Multi-optical axis photoelectric sensor

A photoelectric sensor, multi-optical axis technology, used in instruments, scientific instruments, photometry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] Hereinafter, preferred embodiments of the present invention will be described based on the drawings.

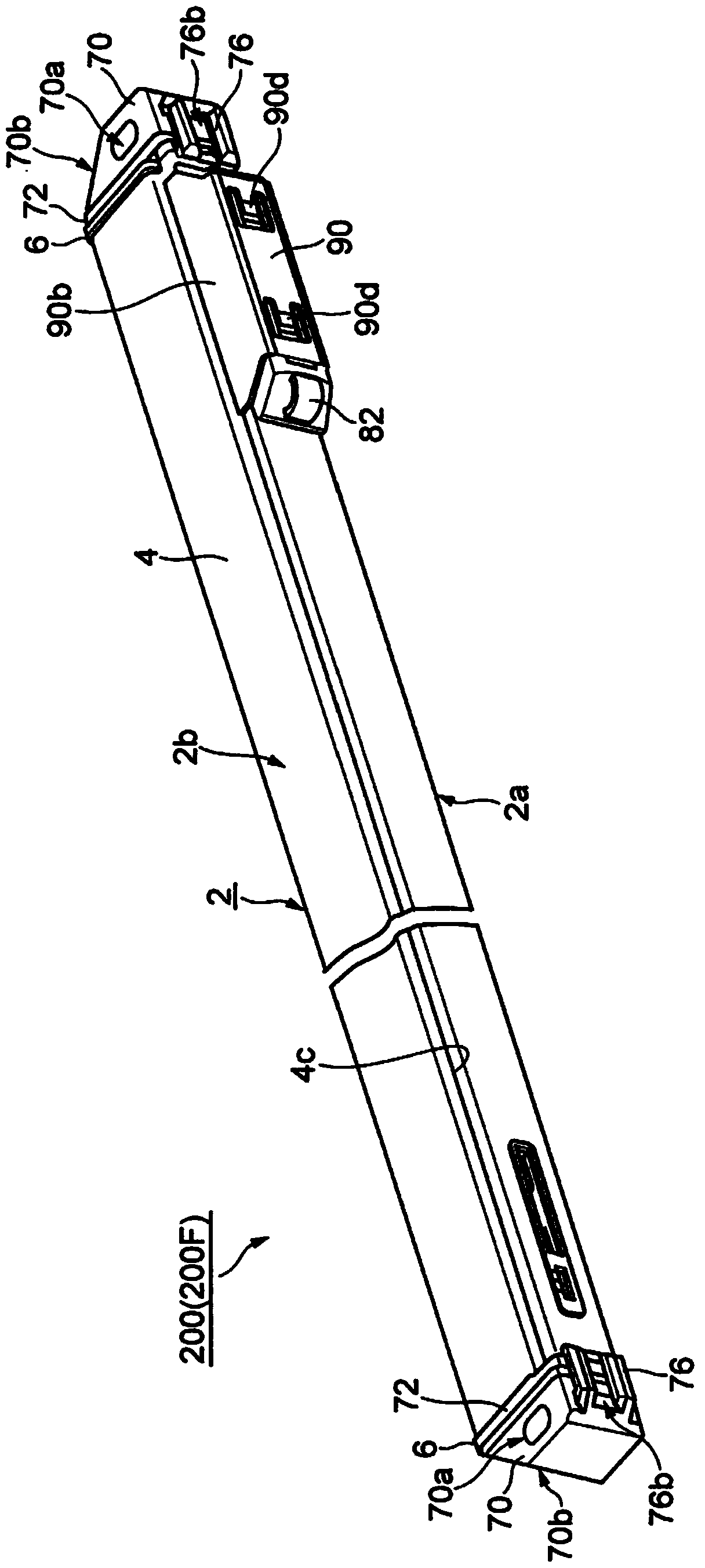

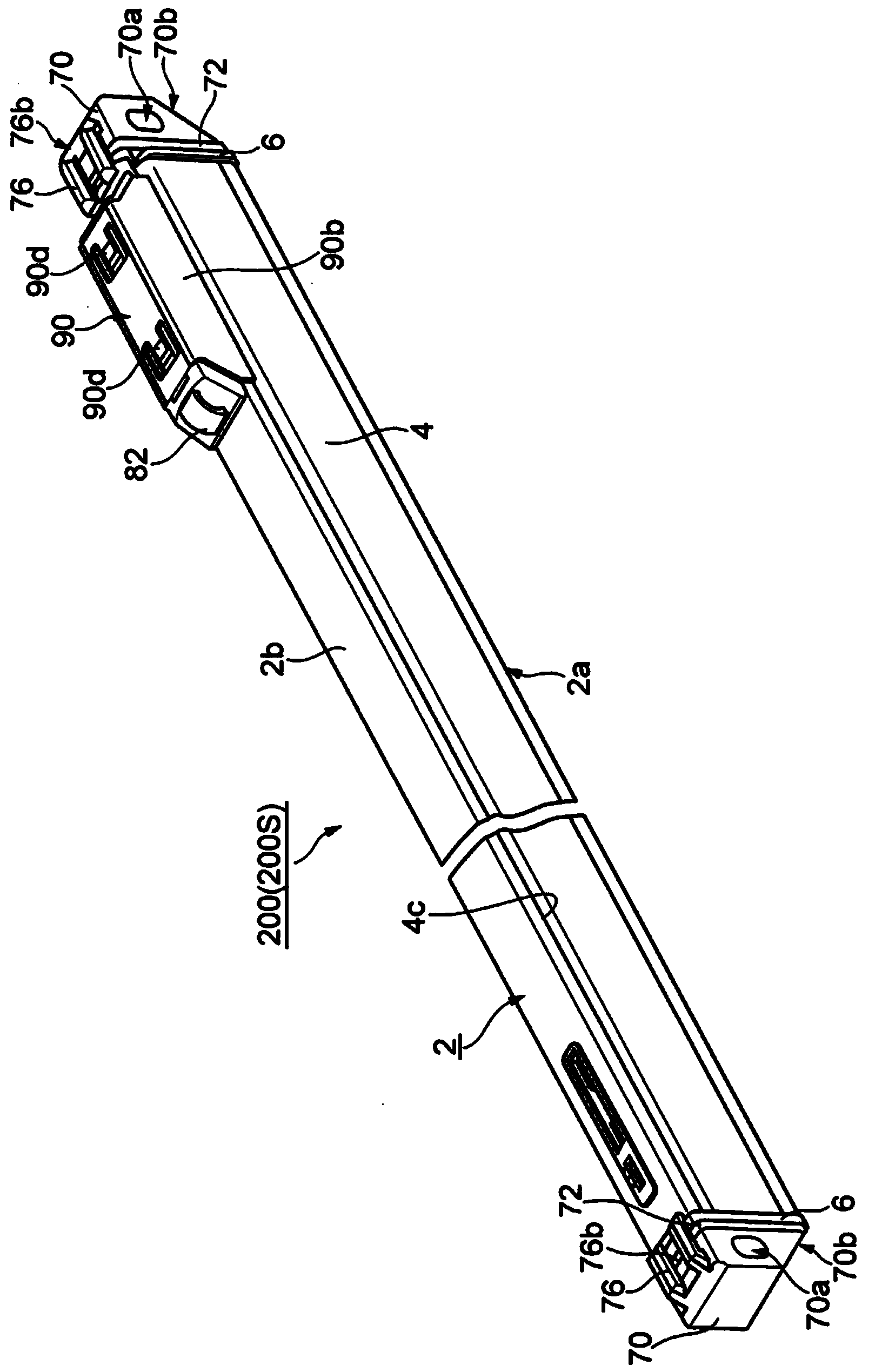

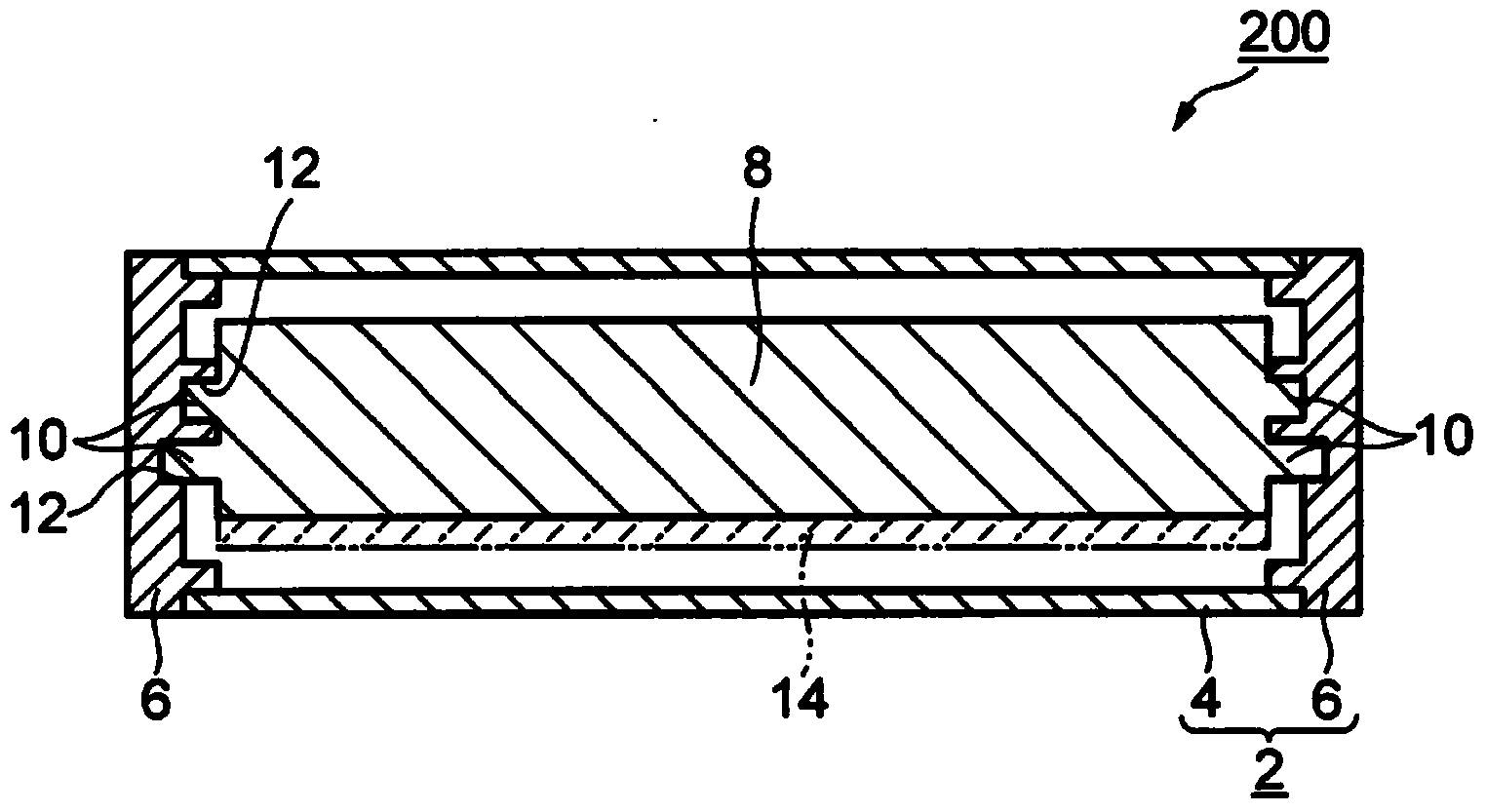

[0064] refer to figure 1 and figure 2 , the multi-optical axis photoelectric sensor 200 of the embodiment includes a housing 2 as a basic element. Two types of sensors 200F ( figure 1 ) and 200S ( figure 2 ).

[0065] available from figure 1 and figure 2 As seen in , the housing 2 has an elongated shape with a substantially rectangular cross-section. figure 1 The first sensor 200F uses a relatively wide surface corresponding to the long side of the rectangle as the light emitting / receiving surface 2a. The first sensor 200S uses a relatively narrow surface corresponding to the short side of the rectangle as the light emitting / receiving surface 2a. exist figure 1 and figure 2 In , the first sensor 200F and the second sensor 200S are shown as having a light emitting / receiving surface 2 a facing downward and a rear surface 2 b facing upward.

[0066] exist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com