Paper folding device

A paper stacking and paper feeding technology, applied in the direction of folding thin materials, transportation and packaging, function indication, etc., can solve a lot of time and other problems, and achieve the effect of easy resetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

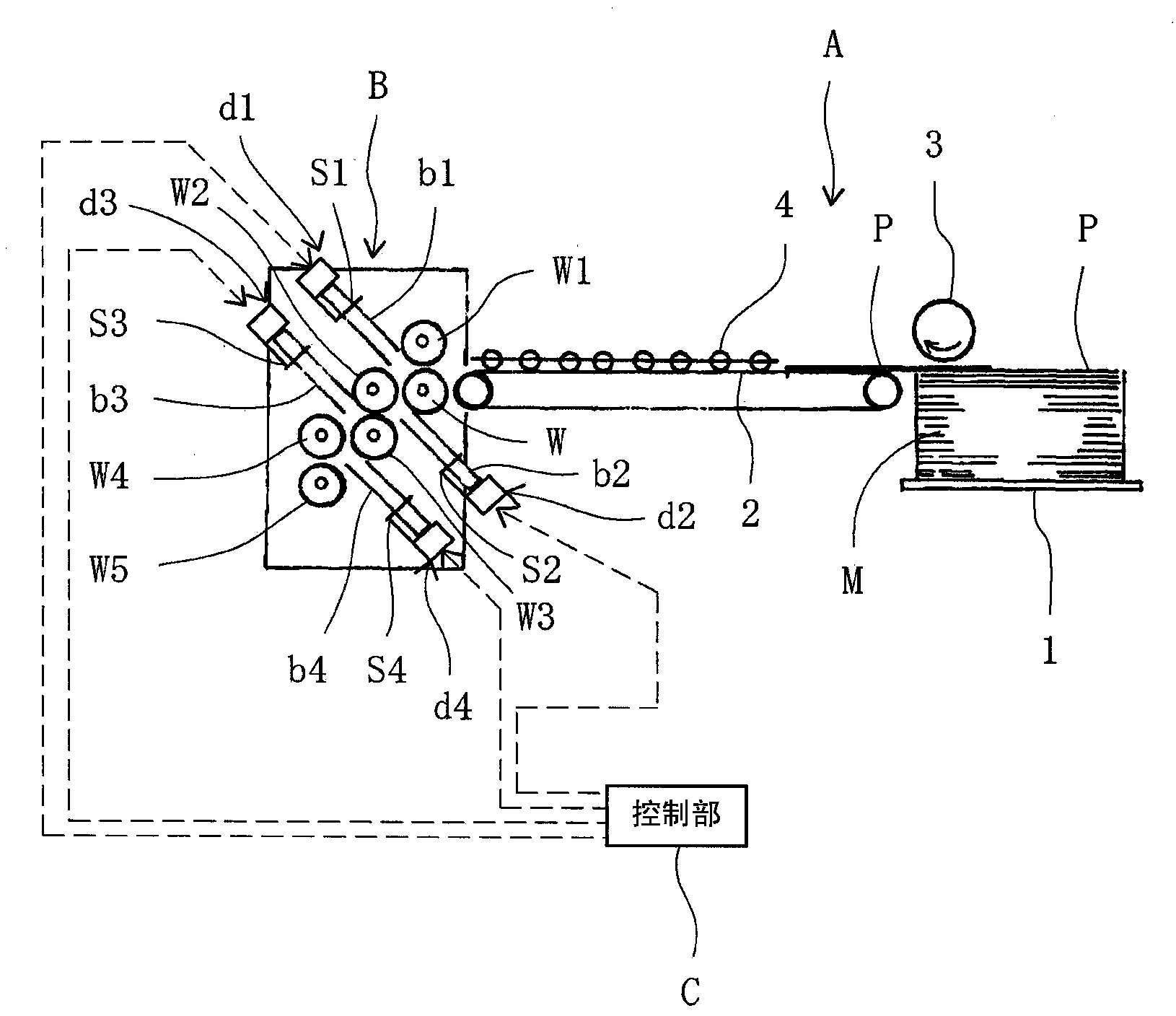

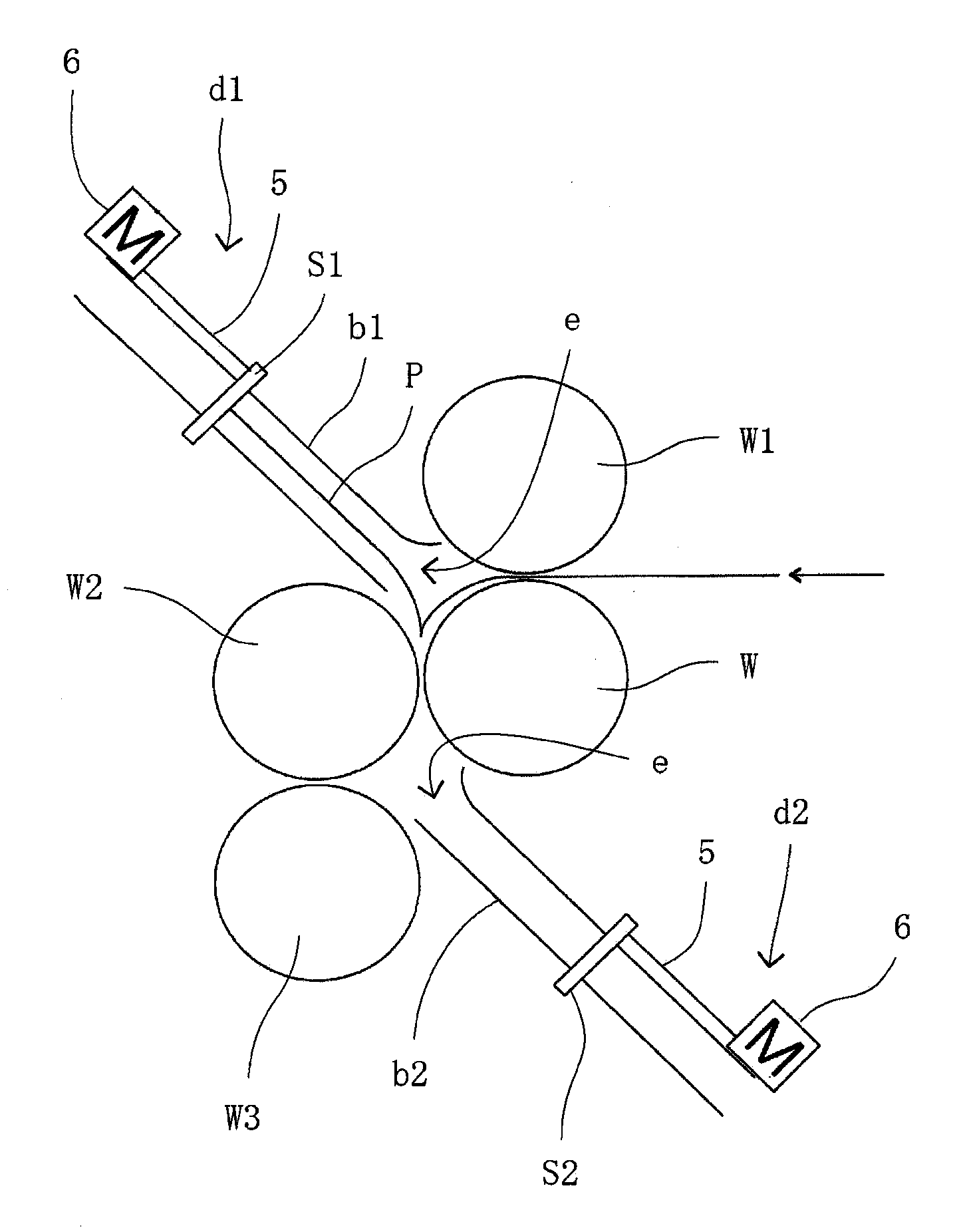

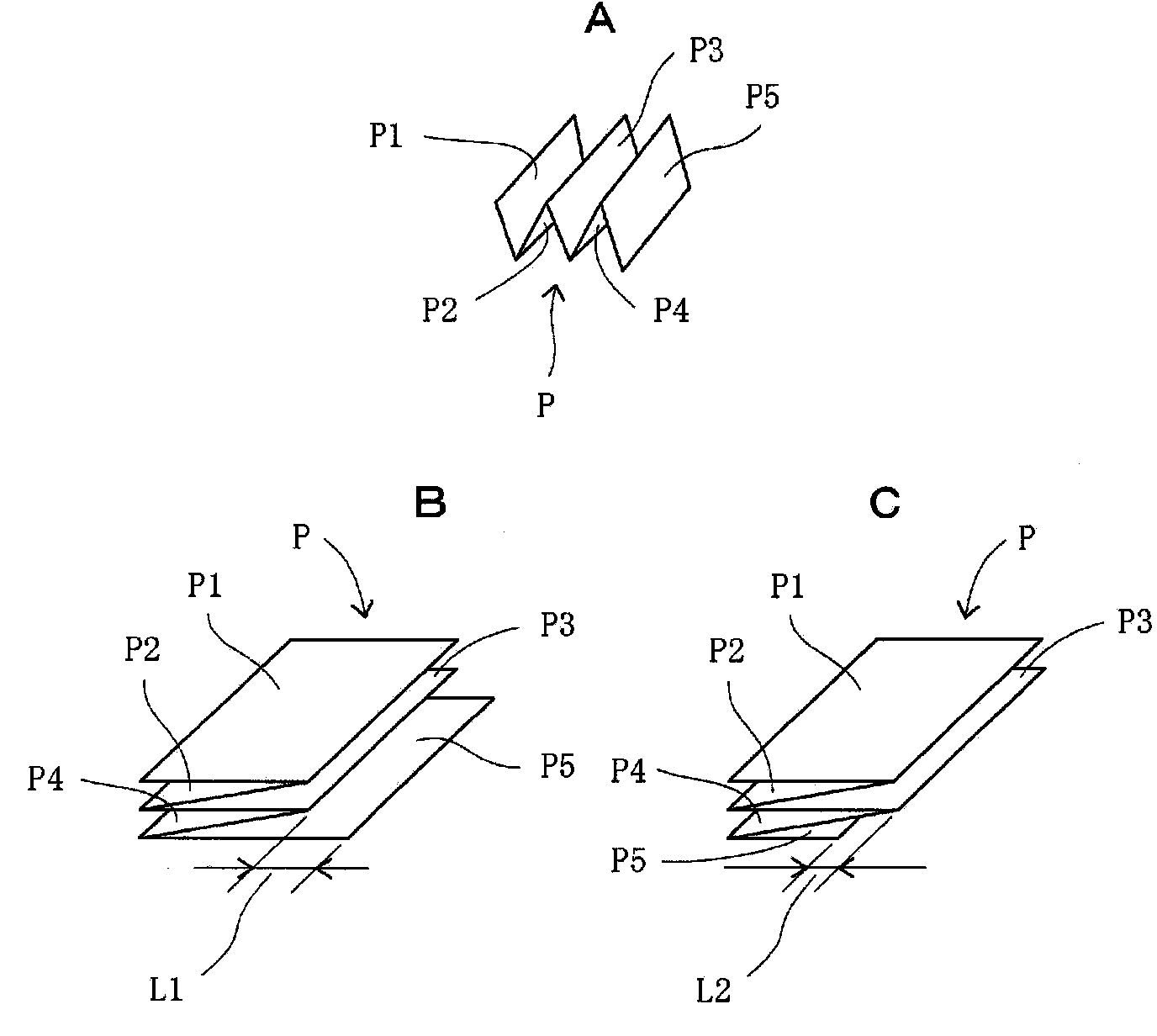

[0029] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. figure 1 is a diagram showing a schematic configuration of an origami device according to an embodiment of the present invention, figure 2 yes means figure 1 An enlarged view of the structure of the folding section of the folding device shown.

[0030] refer to figure 1 The paper folding apparatus of the present invention includes a paper feeding unit A that sequentially feeds paper P from a paper pile M, and a paper folding unit B that folds the paper P fed from the paper feeding unit A at right angles to the paper feeding direction.

[0031] The paper supply unit A has: a shelf 1 on which a stack of paper M is placed and can be raised and lowered; a conveyor belt 2 extending between the shelf 1 and the folding unit B; The uppermost paper P is sequentially fed to the paper feeder 3 on the conveyor belt 2 . In this embodiment, the paper feeder 3 is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com