Bush stubble stumping machine with automatic reset safe hood

A technology of automatic reset and safety cover, which is applied in agricultural machinery and implements, cutting tools, cutting equipment, etc., can solve the problems of operator injury and lack of protective safety cover for flat stubble saw blades, and achieves increased equipment processing cost and simple structure. , the effect of flexible movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

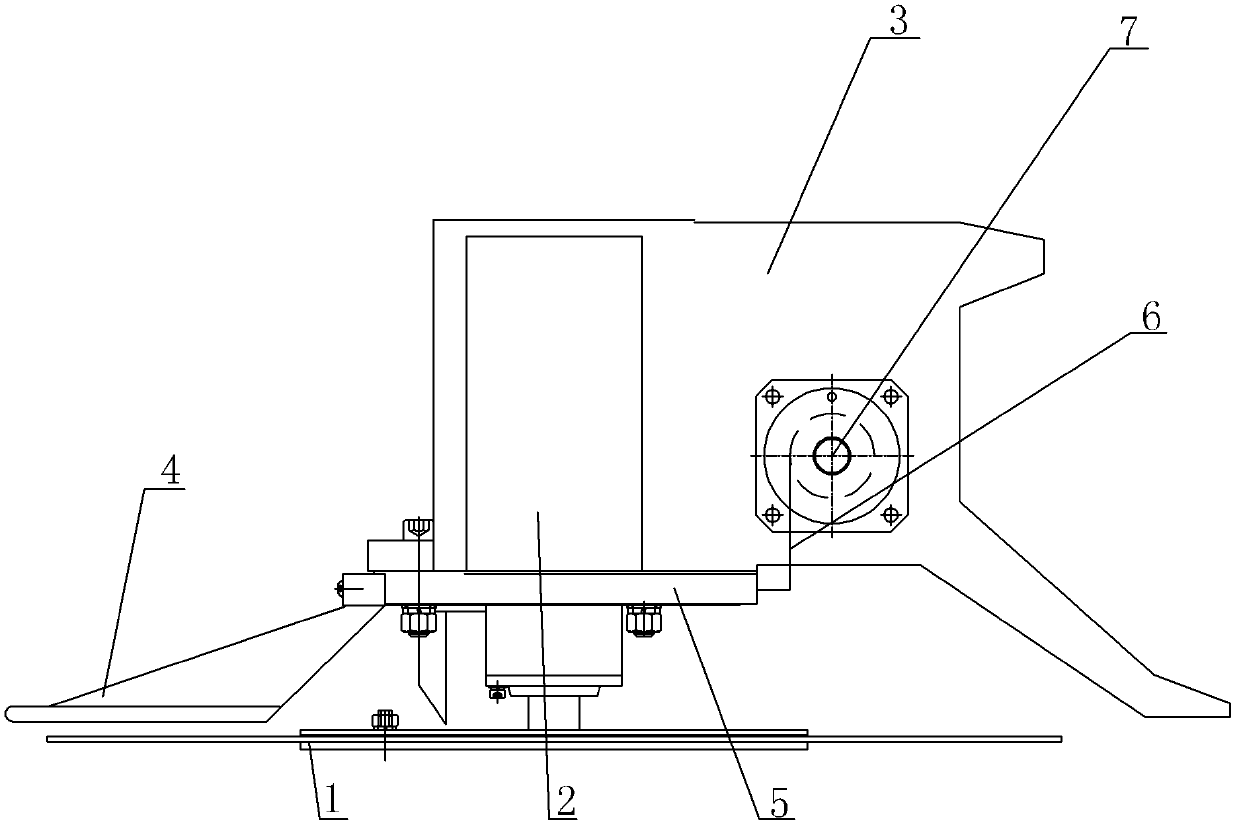

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, a kind of shrub stubble machine with automatic reset safety cover described in this embodiment includes saw blade 1, drive motor 2 and chassis 3, drive motor 2 is installed in chassis 3, and drive motor 2 The axis of the output shaft is perpendicular to the horizontal plane, the saw blade 1 is set on the output shaft of the drive motor 2, and the saw blade 1 is located under the chassis 3, and this embodiment also includes a safety cover 4, a rotor 5, a wire rope 6 and a reset mechanism 7 , the rotor 5 is set on the output shaft of the drive motor 2, and the rotor 5 is located between the lower surface of the chassis 3 and the saw blade 1, the safety cover 4 is connected to the edge of the rotor 5, and the safety cover 4 is located at the front end of the chassis 3 One end of the wire rope 6 is fixedly connected to the edge of the rotor 5, and the other end of the wire rope 6 is connected to th...

specific Embodiment approach 2

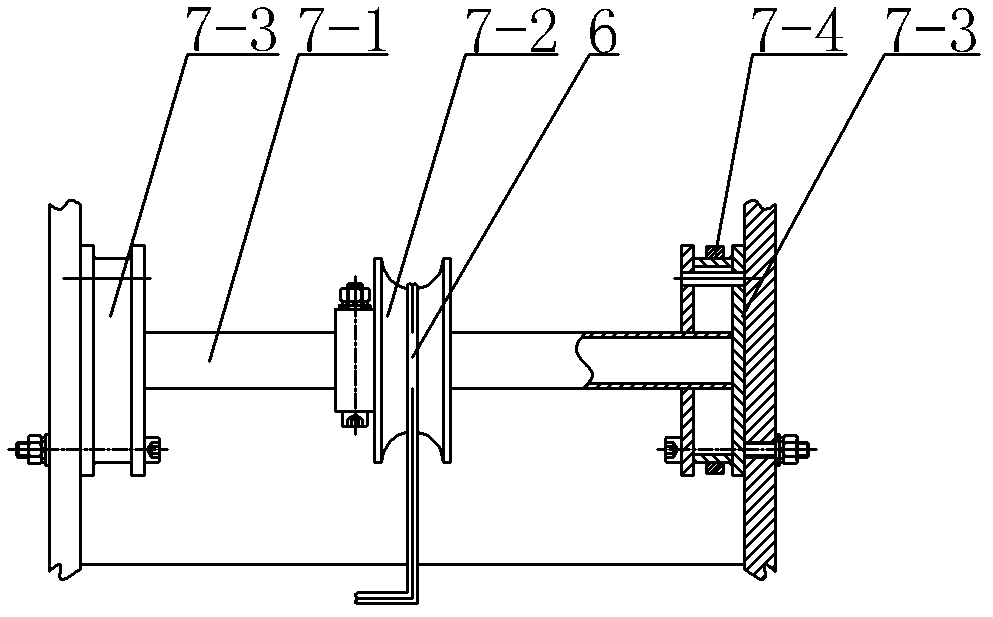

[0009] Specific implementation mode two: combination figure 2 Describe this embodiment, the resetting mechanism 7 of a kind of shrub stubble machine with automatic reset safety cover described in this embodiment includes a shaft tube 7-1, a steel wire winding roller 7-2, two coil spring boxes 7-3 and two A coil spring 7-4, two coil spring boxes 7-3 are respectively arranged side by side on the underframe 3 in parallel, the two ends of the shaft tube 7-1 are respectively connected with a coil spring box 7-3, and the steel wire winding roller 7- 2 are set on the middle part of the shaft tube 7-1, each coil spring 7-4 is wound in a coil spring box 7-3 respectively, and the other end of the steel wire rope 6 is wound on the steel wire winding roller 7-2. Other components and connections are the same as those in the first embodiment.

[0010] working principle

[0011] When performing bush stubble operations, the output shaft of the driving motor 2 rotates and drives the rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com