Motor vehicle lighting device with a coupling lens and a transport and conversion lens

A technology for optical devices and lighting devices, which can be applied to lighting devices, fixed lighting devices, components of lighting devices, etc., and can solve the problems of not being oriented in parallel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The same reference numbers in the various figures here indicate respectively identical or at least functionally similar elements.

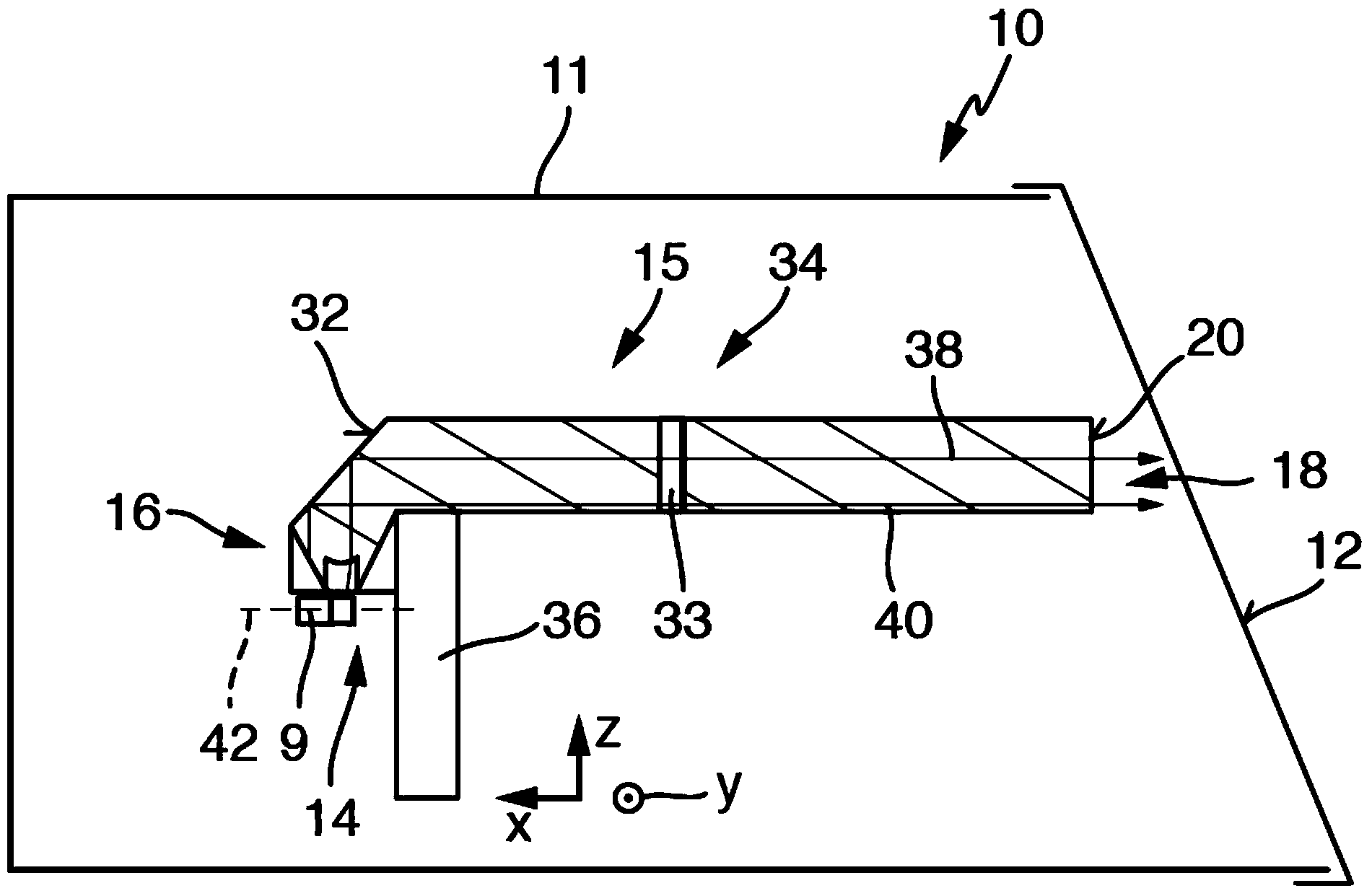

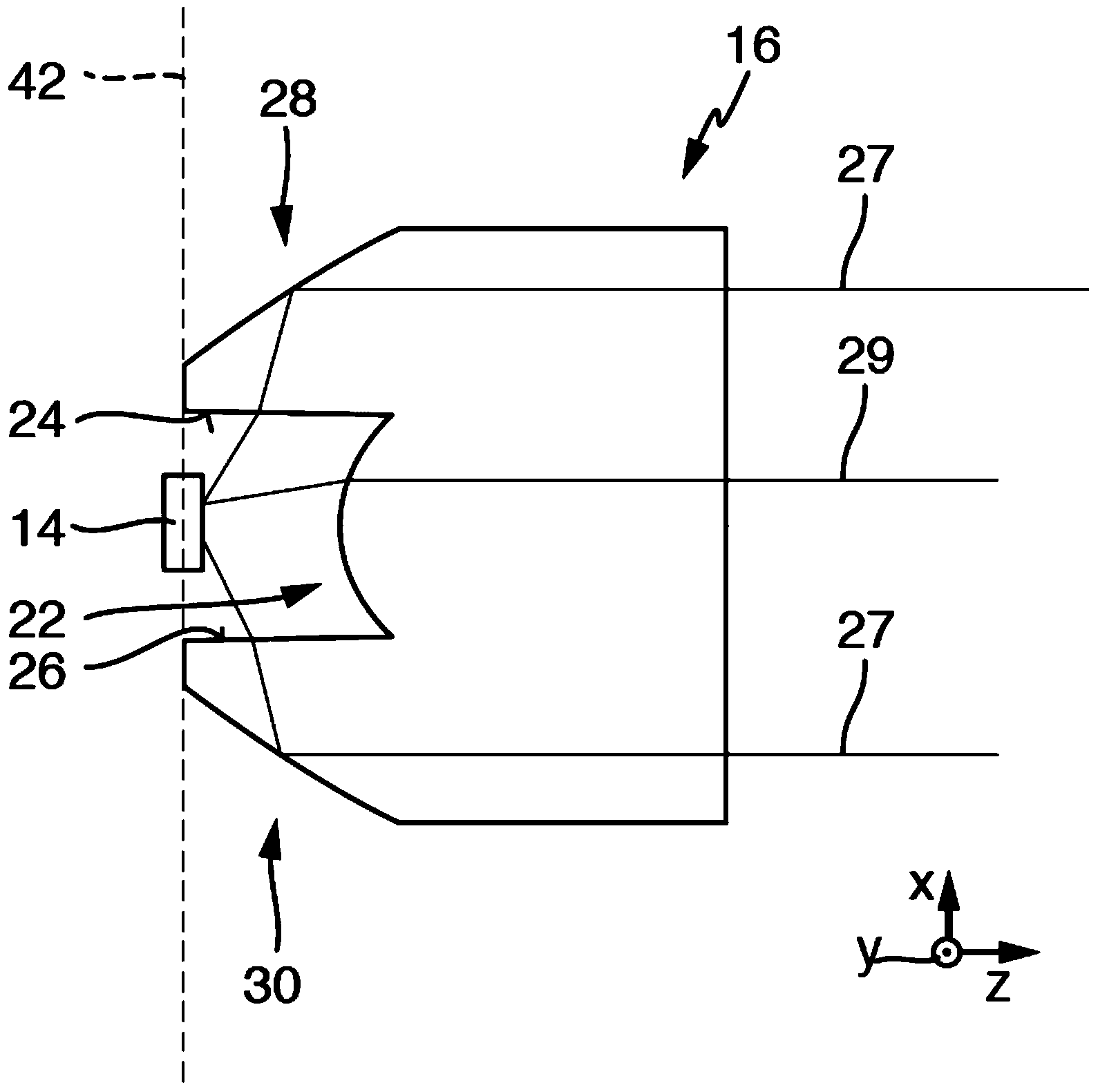

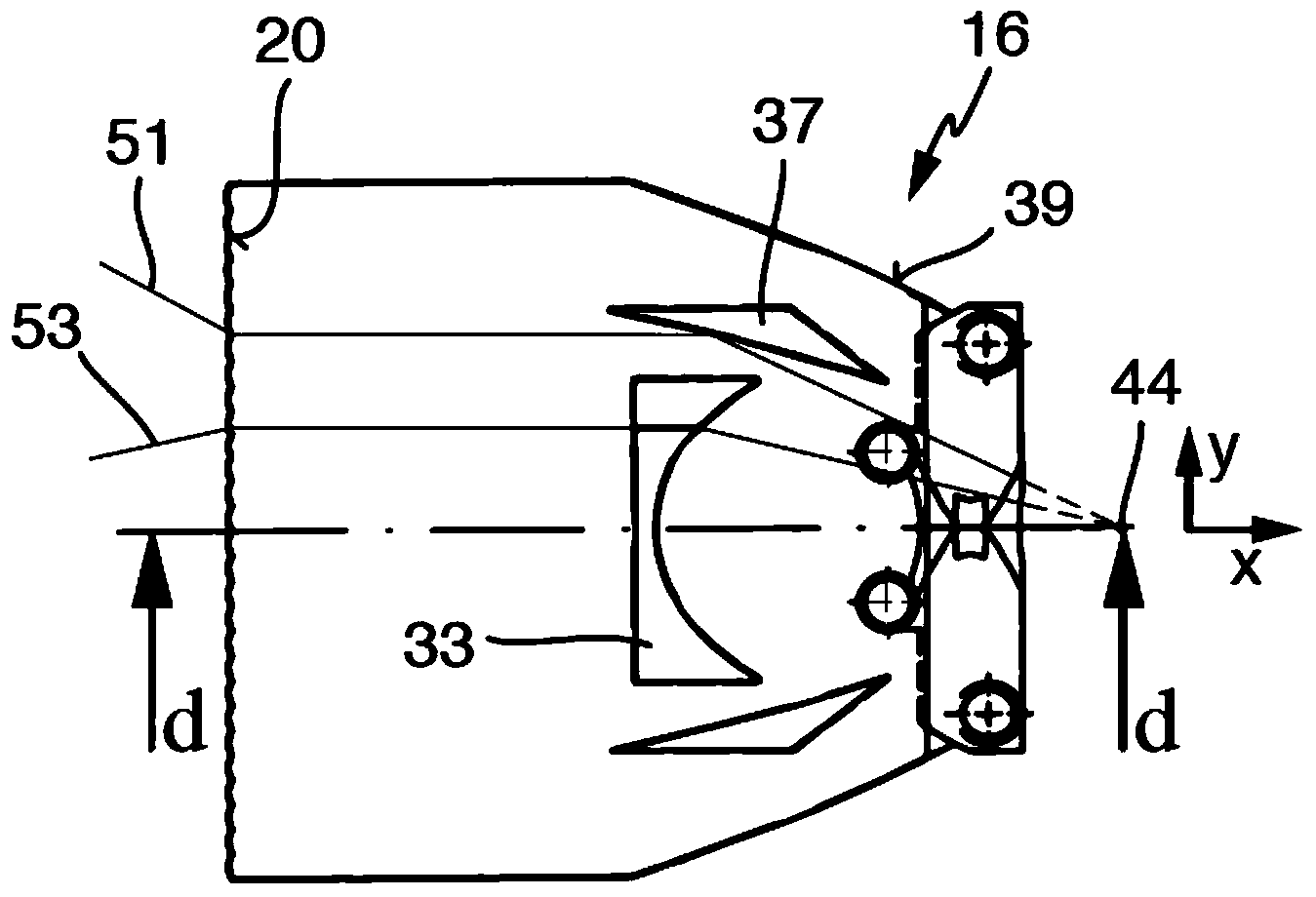

[0042] figure 1 Shown is a motor vehicle lighting device 10 with a housing 11 whose light exit opening is covered by a transparent dust cover 12 . The light source 14 held in a fixed position in the housing and the light guide arrangement 15 with the coupling optics 16 and the transmission and deformation optics 18 are located in the interior of the housing. Both the coupling optics 16 and the transmission and anamorphic optics 18 consist of a transparent light-conducting material, such as PC, PMMA, glass, COC or similar transparent materials, at least in the region in which they transmit the light from the light source 18 .

[0043]The transmission and anamorphic optics 18 have a light exit surface 20 at one end. The light source 14 is preferably a semiconductor light source, in particular a light emitting diode or a device consisting of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com