A device for separating warhead liner cover and explosive grain column

A drug-type cover and warhead technology, which is applied to ammunition, weapon accessories, offensive equipment, etc., can solve the problems of potential safety hazards, explosions, hot spot combustion, etc., and achieve the effect of improving the degree of protection and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

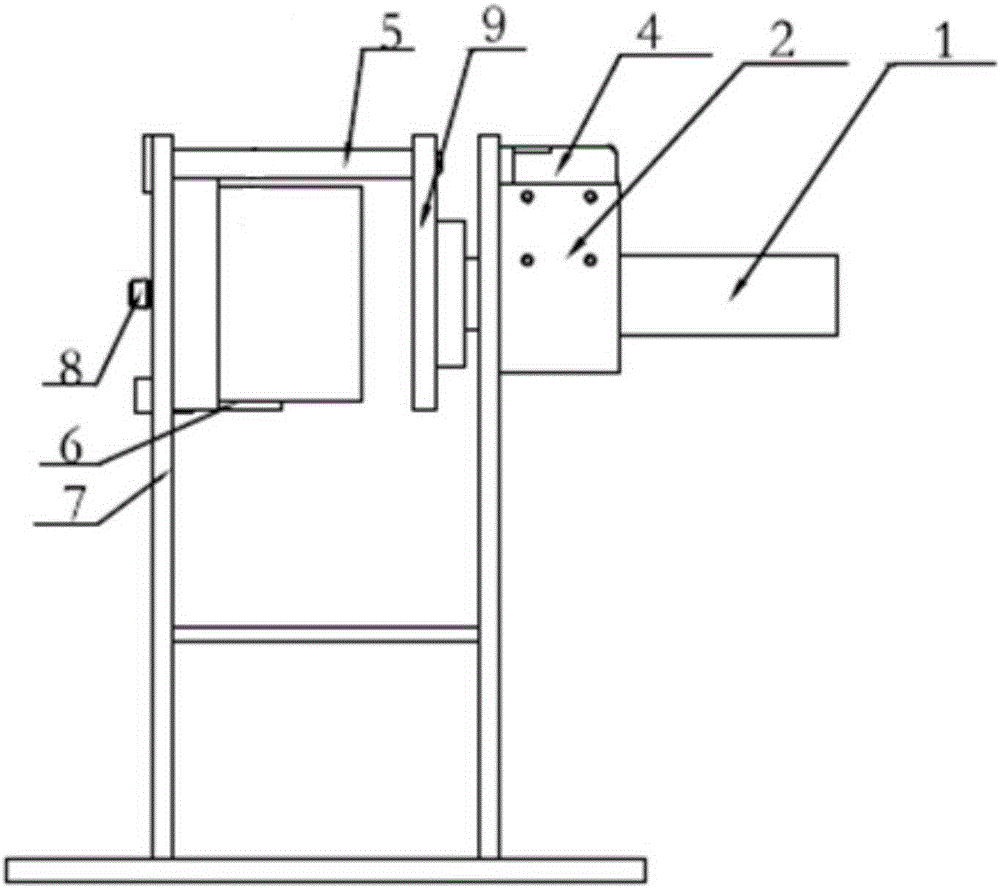

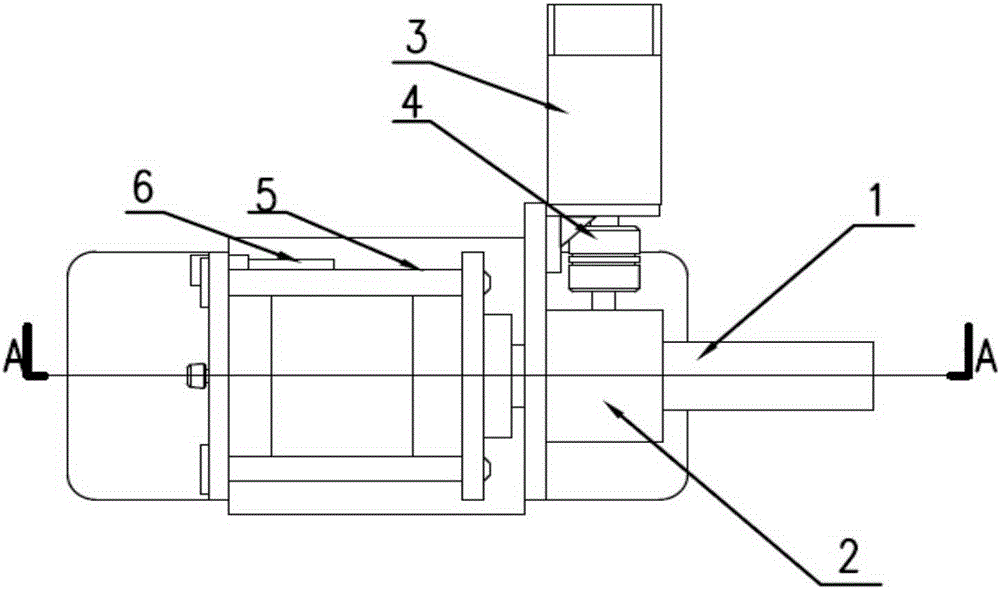

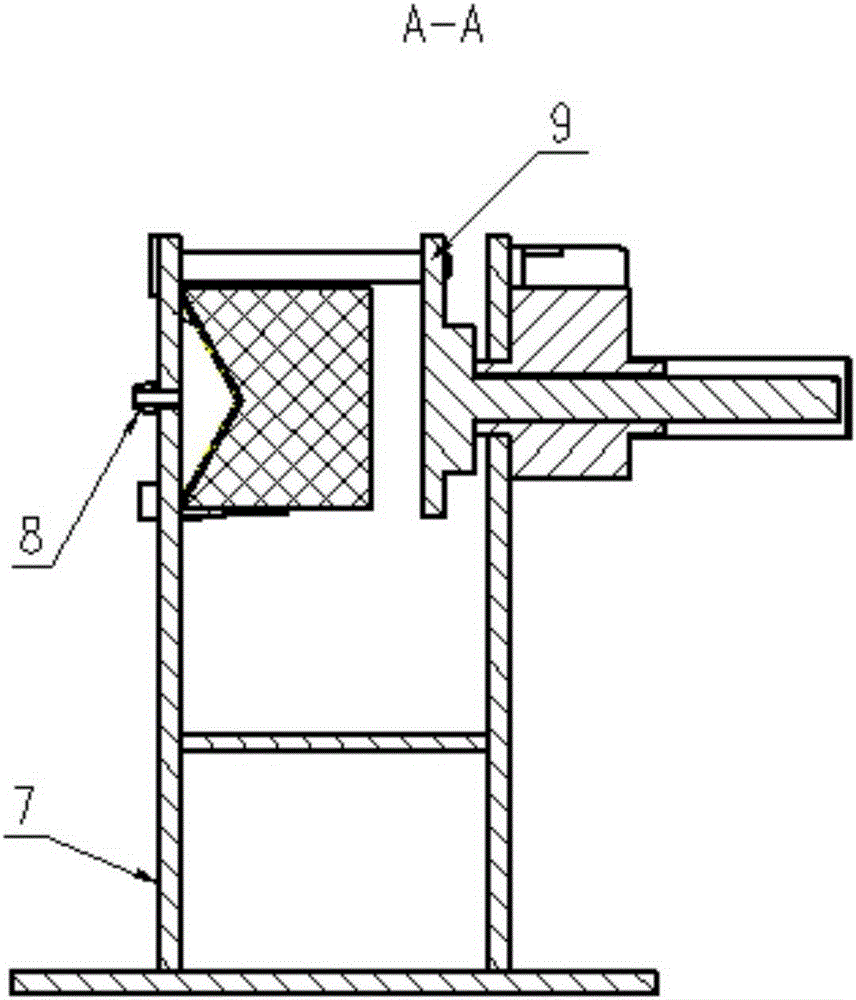

[0014] This embodiment is an example in which the drug-shaped cover and the explosive column of an armor-piercing projectile are separated by a device for separating the drug-shaped cover and the explosive column.

[0015] The outer dimensions of the liner cover and the explosive column used in this embodiment are 120mm in diameter and 135mm in height.

[0016] Before the liner is separated from the explosive column, first adjust the length of the adjustable stop block 6 to make it greater than the height of the liner; then place the open side of the liner facing the end face of the vacuum port 8, and turn on the vacuum pump at the same time. Fix the liner and the explosive column on the end face of the vacuum port 8; evacuate the personnel, start the explosion-proof stepping motor 3, adjust the motor speed so that the pressure plate moves towards the explosive column at any speed between 10mm / min and 60mm / min , when the extrusion pressure of the pressing plate is greater than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com