Crane Type Marine Cryogenic Fluid Filling Equipment

A low-temperature fluid and filling equipment technology, applied in mechanical equipment, equipment loaded into pressure vessels, cranes, etc., can solve problems such as difficulty in meeting user requirements, and achieve the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

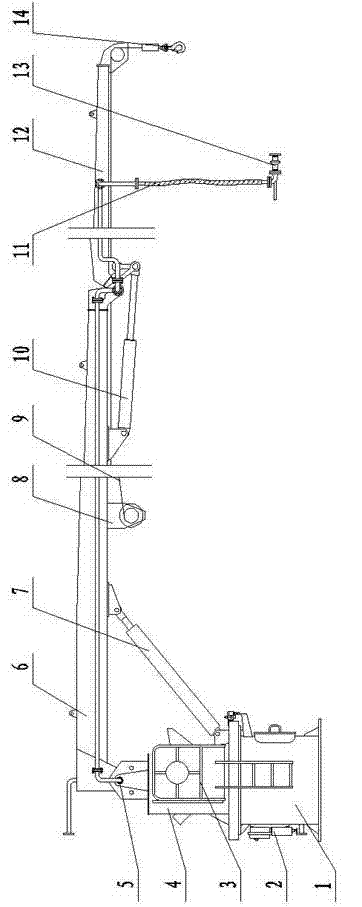

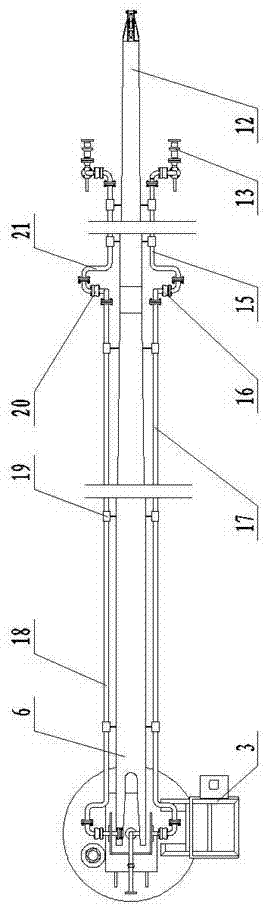

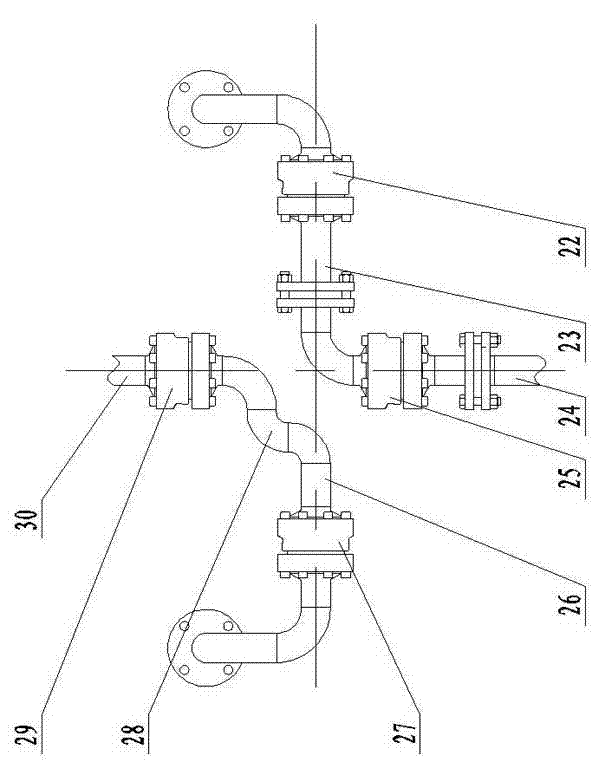

[0014] A crane-type marine low-temperature fluid filling equipment, including a base 1, a vertically arranged rotating column 4 is installed on the upper end of the base 1 through a slewing support, and a horizontally arranged hinge shaft 5 is installed above the rotating column 4 A main boom 6 is articulated, a main luffing mechanism 7 is arranged between the main boom 6 and the rotating column 4, and an auxiliary boom 12 is hinged at the front end of the main boom 6 through a pin shaft arranged parallel to the above-mentioned hinge shaft 5, An auxiliary luffing mechanism 10 is provided between the auxiliary boom 12 and the main boom 6, a fixed pulley is arranged at the outer end of the auxiliary boom 12, a hydraulic winch 8 is arranged in the middle of the main boom 6, and a hydraulic winch 8 A sling 9 is wound on the top, and the free end of the sling 9 bypasses the above-mentioned fixed pulley and is connected with a suspension hook 14; the left and right sides of the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com