Method for accurately controlling trimming line of turned edge under complex curved surface

A technology for flanging and trimming lines and complex surfaces, which is applied in special data processing applications, instruments, electrical and digital data processing, etc. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the scope described in the embodiments.

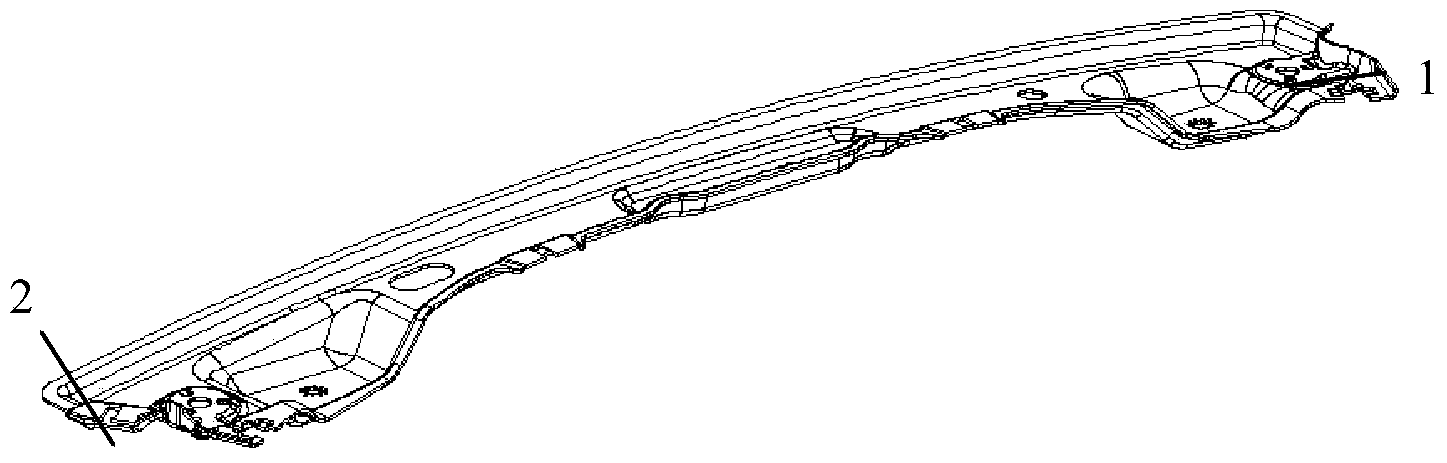

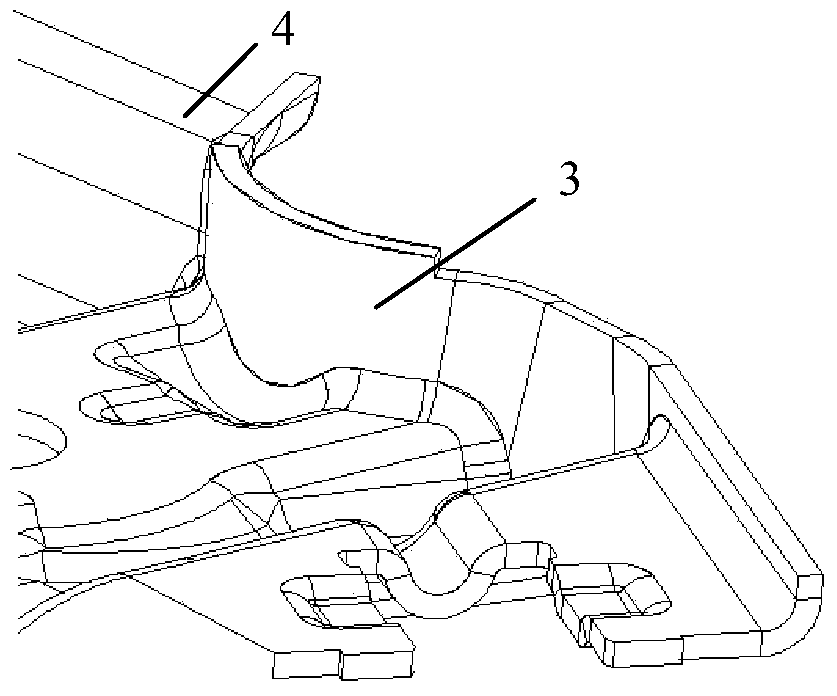

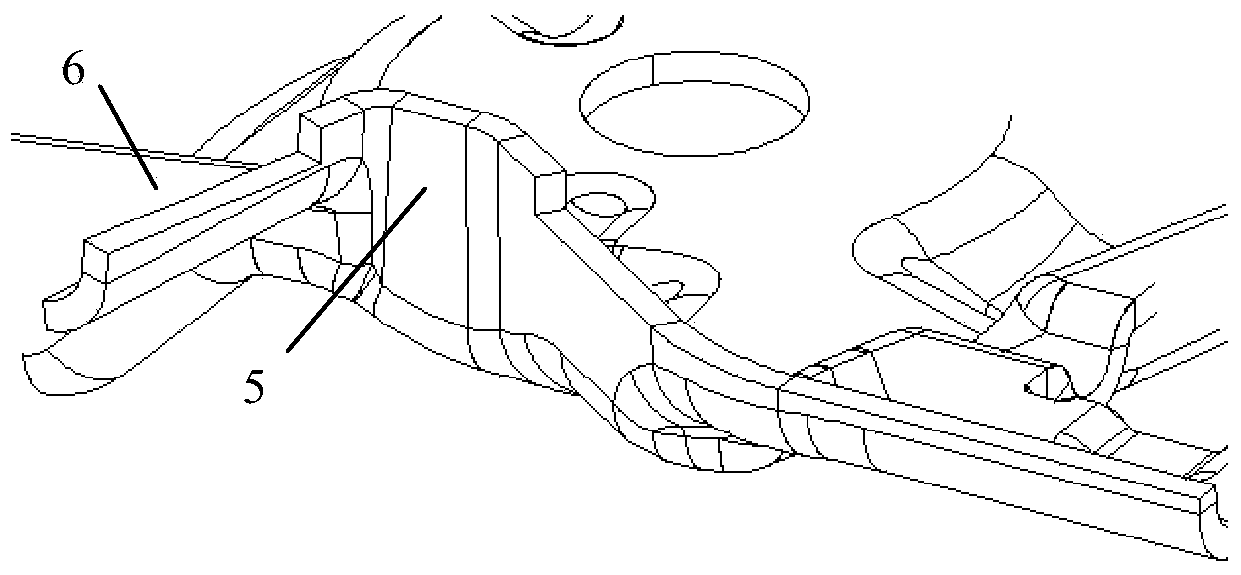

[0040] like figure 1 As shown, the part to be processed is a car door glass guide rail structure, the material is galvanized sheet, the thickness of the material is 1.2mm, and it is used for the electric glass regulator of the car. The door glass guide rail structural part has a complex curved surface; the upper and lower ends of the door glass guide rail structural part are upper flange 1 and lower end flange 2, and the flange edge precision of the door glass guide rail structure requires high precision and the error of some areas is controlled at 0.8 per side within mm. As shown in Fig. 2(a) and Fig. 2(b), the surfaces of the upper end flanging shape 3 and the lower end flanging shape 5 of the door glass guide rail structure are complex curved surfaces combine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com