Production method of bottle type honeycomb honey

A production method and technology of honeycomb honey, which is applied in the field of bottle honeycomb honey production, can solve the problems of pollution, inedible paraffin components, and the pure nature of honeycomb honey, and achieve the effect of solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

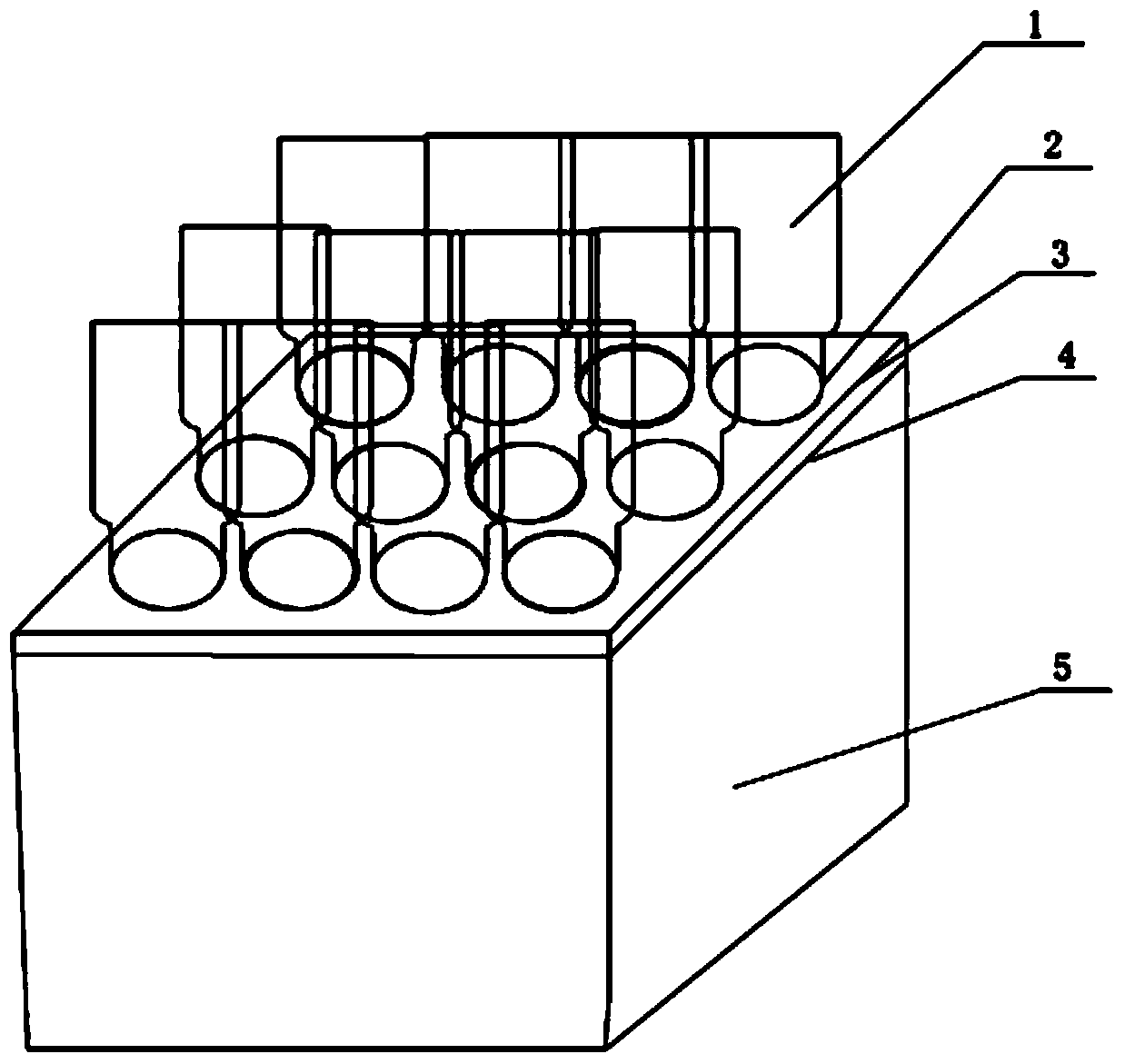

[0010] 1. Select a group of 12 large-diameter glass bottles 1, the size of the bottle mouth can be inserted into the size of the glass bottle mouth hole 2 reserved on the isolation plate 3, and use this glass bottle 1 as a bottle for brewing honey and packaging to consumers Put fresh honeycomb pieces in the bottle, melt the side of the honeycomb piece and stick it on the bottom or side wall of the glass bottle as an inducer.

[0011] 2. Make the upper cover of the beehive 5, reserve a hole the size of the bottle mouth on the upper cover as the isolation plate 3, attach the metal screen 4 to the lower layer of the isolation plate 3, and insert the glass bottle with the honeycomb upside down A group of glass bottles are lined up in the holes of the isolation plate.

[0012] 3. After the bees enter the honey bottle to build nests and make honey, and when the honeycomb in the bottle is full, take out the honey bottle, seal the bottle cap and put it on the market.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com