Implanted electrode compatible with MRI and manufacturing method thereof

A manufacturing method and implantable technology, applied in the direction of electrodes, internal electrodes, etc., can solve the problems of high current density, ohmic heating, etc., and achieve the effects of ensuring safety, eliminating heat generation, and changing the properties of transmission lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The MRI compatible implantable electrode provided by the present invention and its manufacturing method will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

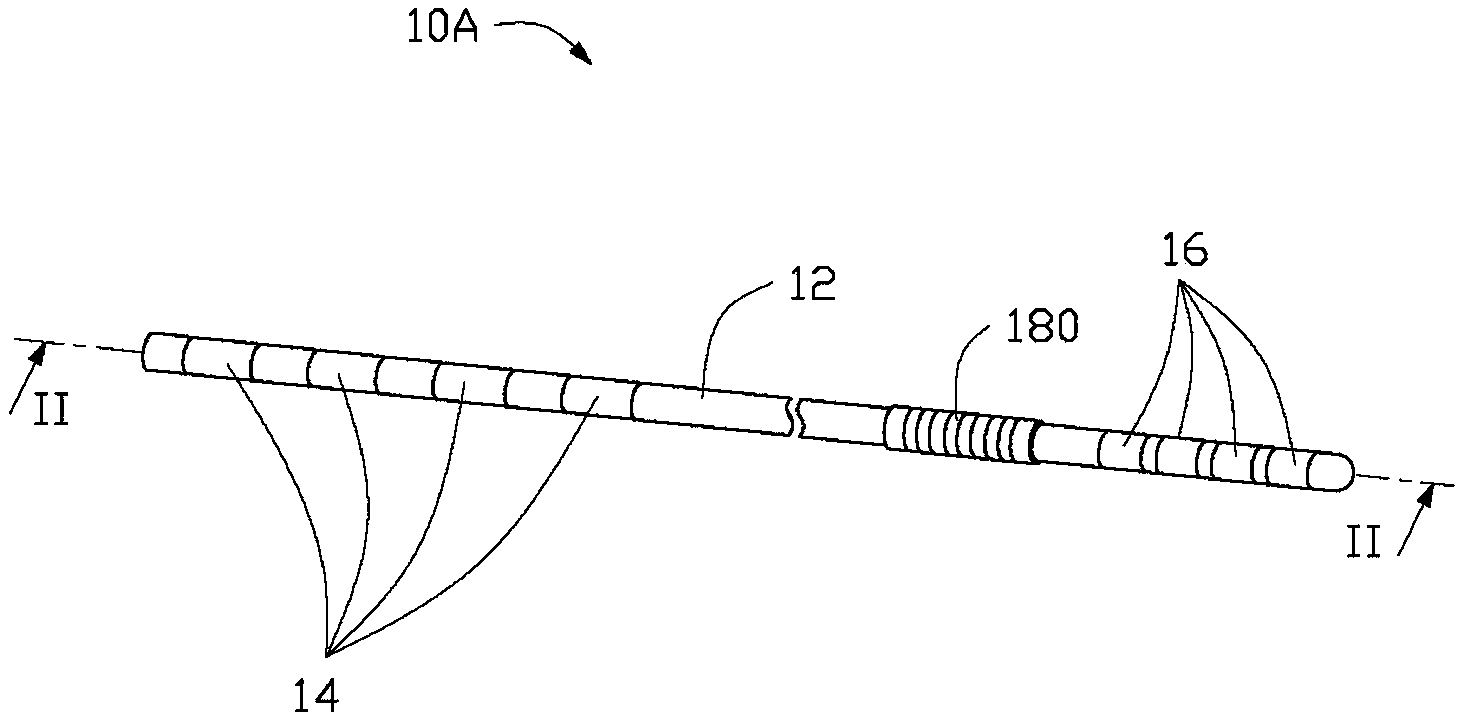

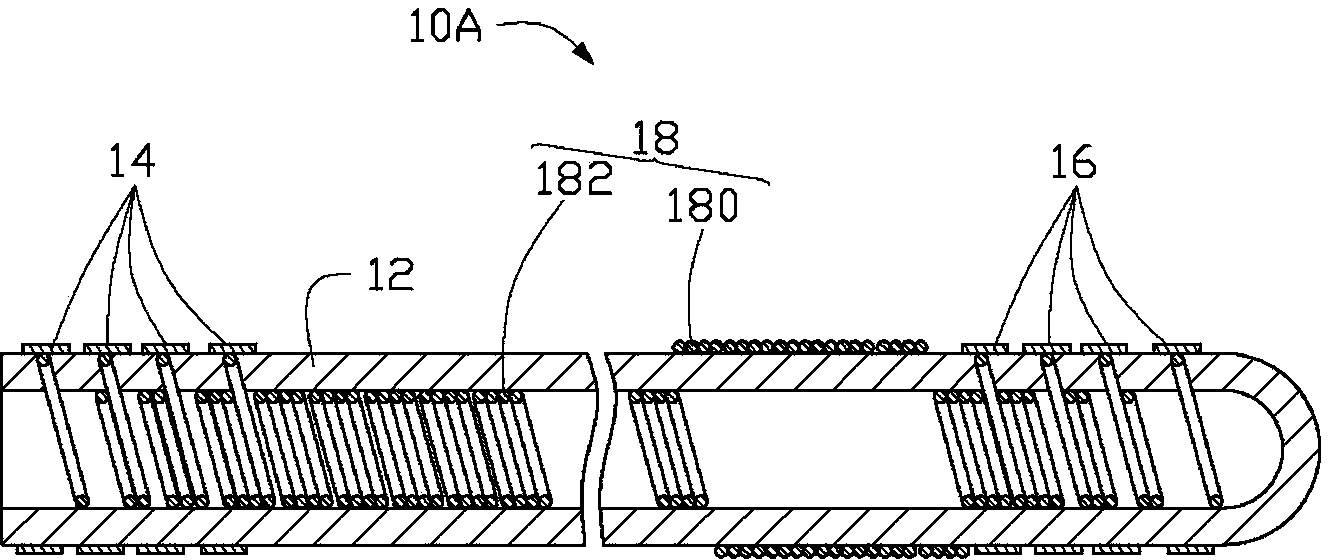

[0027] See Figure 1-2 , the first embodiment of the present invention provides an MRI compatible implantable electrode 10A, which includes: a flexible insulating conduit 12, the flexible insulating conduit 12 has a first end and a second end opposite to the first end end; at least one connector 14 is arranged on the outer surface of the first end of the flexible insulating conduit 12; at least one contact 16 is arranged on the outer surface of the second end of the flexible insulating conduit 12; and a helical wire 18 is arranged on the flexible insulating conduit 12 Inside the insulating conduit 12, and the helical wire 18 electrically connects the at least one contact 16 and at least one connector 14; further, the helical diameter of the helical wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com