Cold stripe mill deviation and shape automatic control method

A cold rolling mill and strip technology, applied in the field of strip rolling, can solve the problems of not considering control deviation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

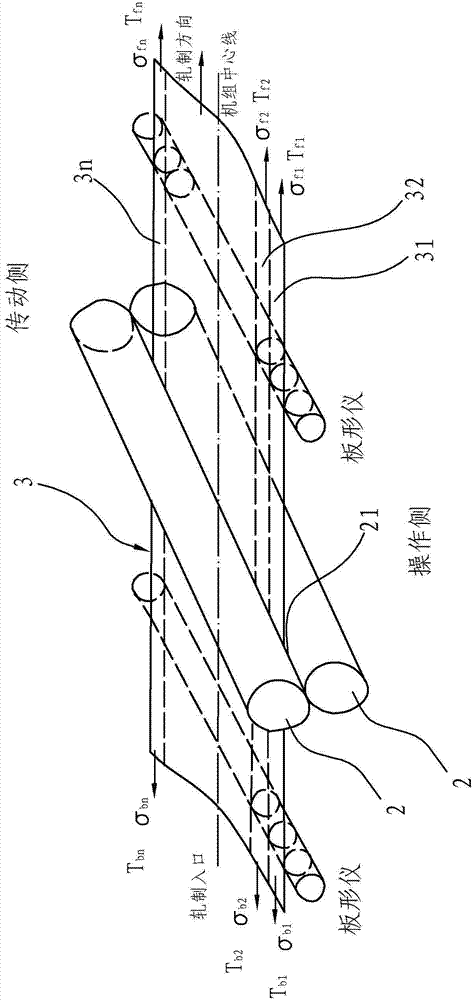

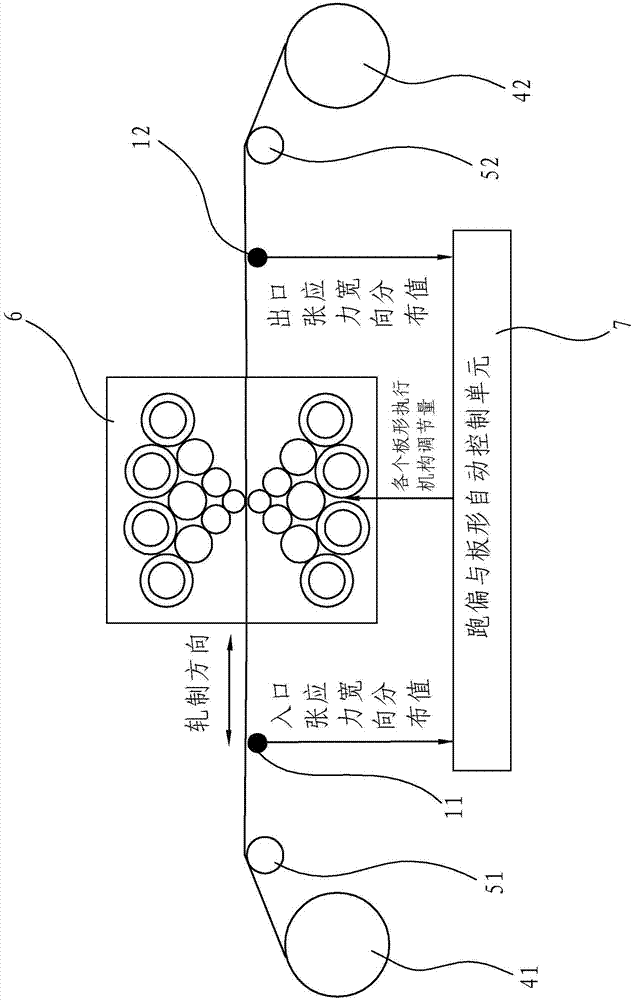

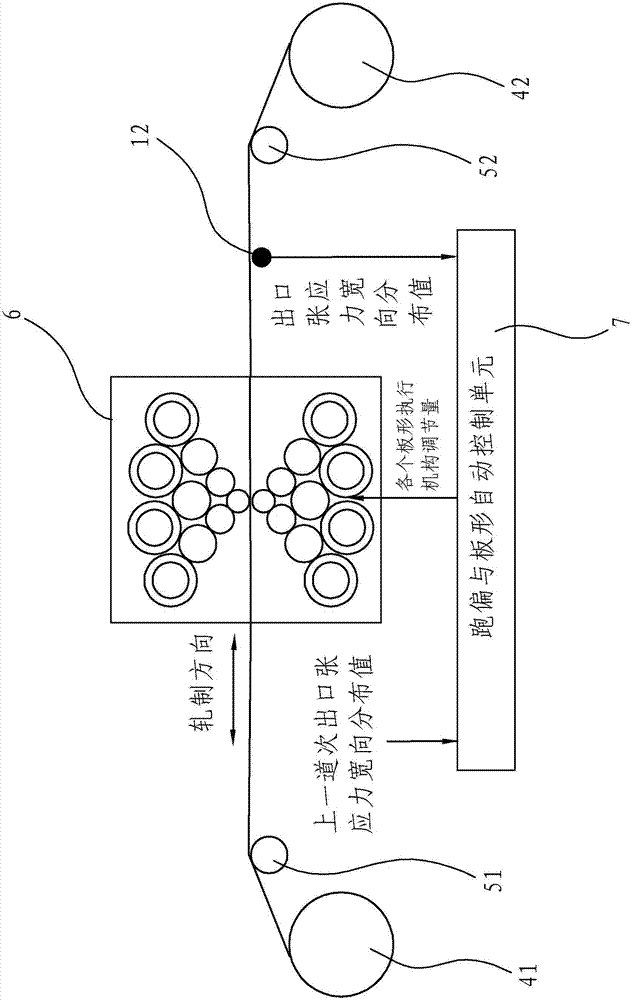

[0044] The cold rolling mill deviation and shape automatic control system adopting the method of the present invention has a plurality of shape actuators and deviation and shape automatic control units 7 for adjusting the shape of the strip, and at the same time, at the entrance of the cold rolling mill and the outlet are equipped with a shape meter, such as figure 2 shown.

[0045] The strip cold rolling mill running deviation and strip shape automatic control method provided by the present invention utilizes the flatness instrument configured at the entrance and exit of the cold rolling mill to detect the strip strip shape before and after the strip cold rolling in real time, and use the The strip shape after rolling and deviation amount of material 3 are taken as comprehensive control targets, and the deviation between the rolled shape and the target shape and the strip deviation amount are comprehensively minimized by automatically adjusting the shape adjustment mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com