Cashmere sweater with uniform fabric thickness and high wearing layered effect

A technology of uniform thickness and cashmere sweater, applied in the field of cashmere sweater, can solve the problems of unfavorable product promotion, uneven thickness of fabrics, single style, etc., and achieve the effect of improving ornamental and aesthetic performance, uniform thickness of fabrics, and high market sales.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

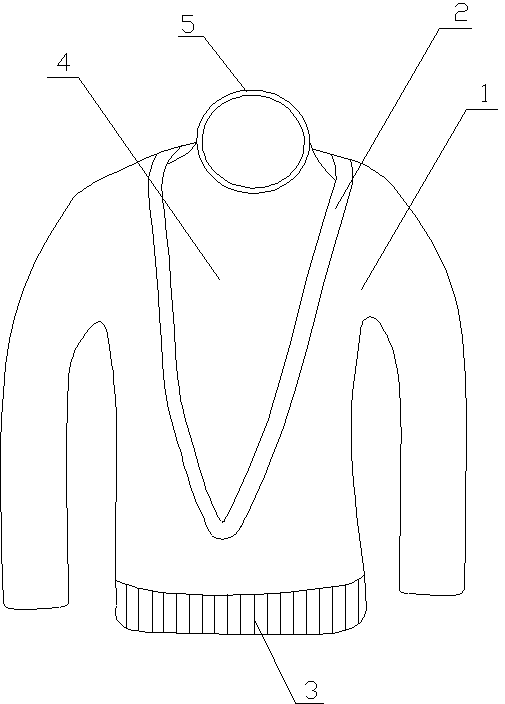

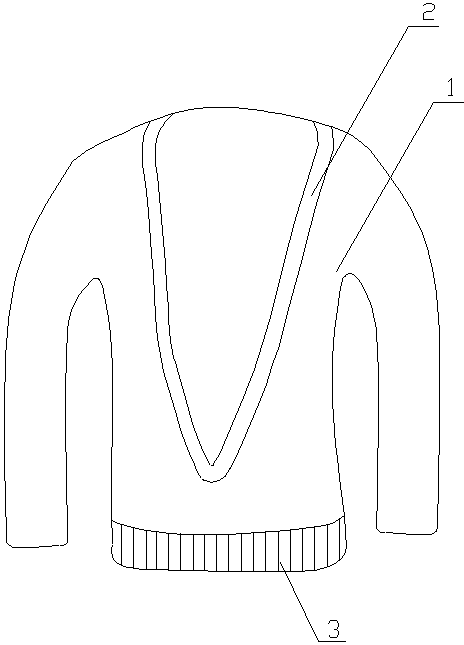

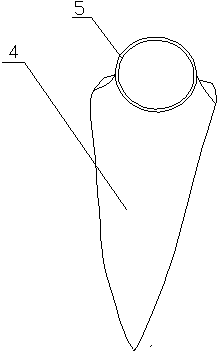

[0016] see Figure 1~3 , the present invention relates to a cashmere sweater with uniform thickness and strong layered fabric, the cashmere sweater includes a clothing body 1, the front body and sleeves of the clothing body are made of cashmere, and the back body of the clothing body is made of fabric , the fabric is a felt fabric, and the felt fabric includes a fixedly connected cloth layer and a wool layer, and the wool layer is a mesh fabric composed of criss-cross wool threads. The neckline of the clothes body 1 is a V-neck 2, and the lower end of the neckline of the V-neck 2 extends to 3 places close to the hem to form a deep V-neck structure, and there is a patch 4 whose shape matches the V-neck 2. The edge is sewn on the edge of the V-neck 2, preferably, the edge of the patch 4 is sewn on the inner side of the V-neck 2, which has two advantages, one is that the seam cannot be seen from the outside, so More attractive in appearance, the 2nd, make the overall sense of la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com