A kind of meat skin cutting machine

A flower cutting machine and meat skin technology, which can be used in cutting meat skin equipment and other directions, can solve the problems of large workload, a lot of manpower and material resources, complicated steps, etc., and achieve the effect of improved work efficiency, consistent cutting depth, and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

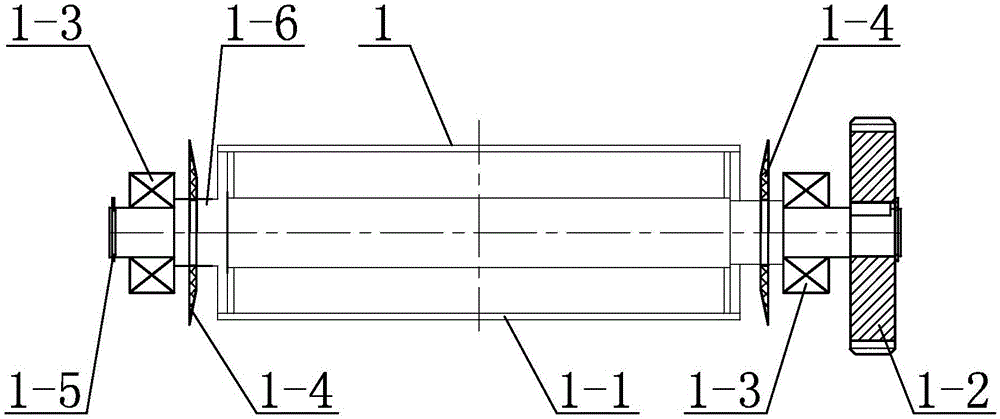

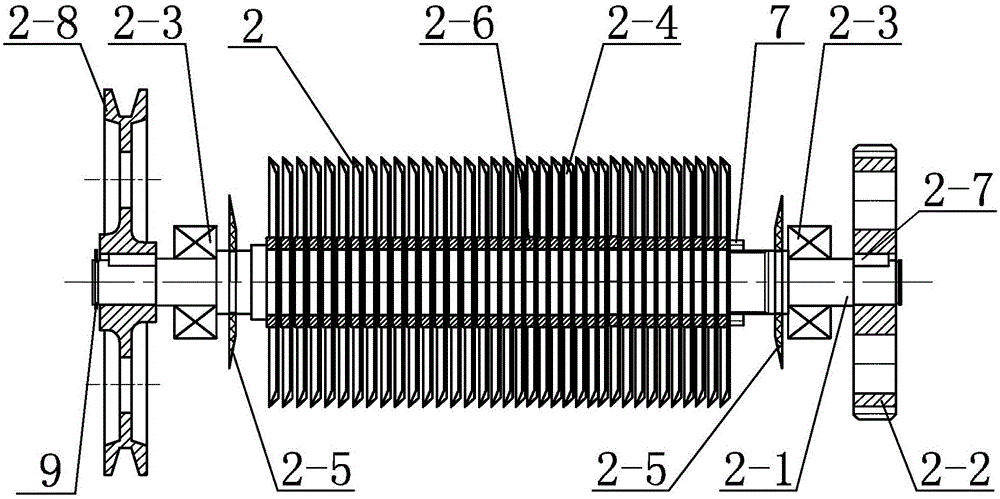

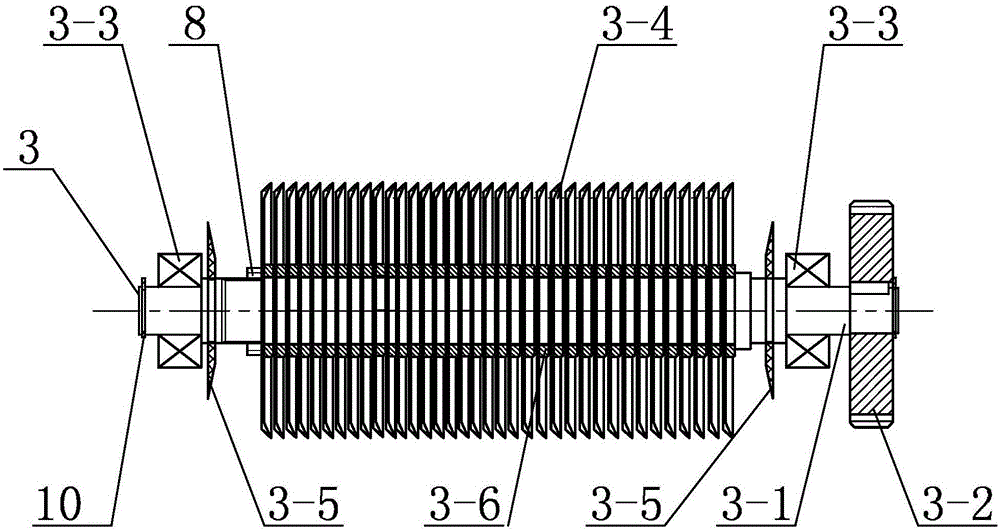

[0012] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 Describe this embodiment, a kind of meat skin cutting flower machine described in this embodiment comprises roller body 1, the first disk blade group 2, the second disk blade group 3, the first comb body 4, the second comb body 5 and machine Frame 6, the roller body 1, the first disc blade group 2, the second disc blade group 3, the first comb body 4 and the second comb body 5 are all located in the frame 6, and the first disc blade group 2 is arranged horizontally with the roller body 1, the second disk blade group 3 is located below the roller body 1 and is provided with a gap with the roller body 1, and the first comb body 4 is arranged near the first disk blade group 2 and Set with the gap of the first disc blade set 2, the second comb plate body 5 is arranged near the se...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 Describe this embodiment, in this embodiment, the first comb body 4 includes a first carding main body 4-1 and a plurality of first combing teeth 4-2, which are evenly distributed on the first carding main body 4-1. A plurality of first combing teeth 4-2, the two ends of the first carding main body 4-1 are detachably connected on the frame 6; the second combing body 5 includes the second carding main body 5-1 and a plurality of The second carding teeth 5-2, a plurality of second carding teeth 5-2 evenly distributed on the second carding main body 5-1, the two ends of the second carding main body 5-1 are detachably connected on the frame 6 . The second comb body 5 is arranged between the outlet of the frame 6 and the second disc blade set 3 and close to the second disc bl...

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 Describe this embodiment, the first disk blade set 2 in this embodiment also includes two first dustproof rings 2-5, and the second disk blade set 3 also includes two second dustproof rings 3-5 , the two first dust-proof rings 2-5 are set on the first rotating shaft 2-1 and located on both sides of a plurality of first disk blades 2-4; the two second dust-proof rings 3- 5 are set on the second rotating shaft 3-1 and located on both sides of the plurality of second disc blades 3-4. In this embodiment, the setting of the two first dust-proof rings 2-5 is to prevent other particles such as dust from entering the plurality of first disk blades 2-4 when the first rotating shaft 2-1 rotates to cut the meat skin. A plate of blades 2-4 affects the normal use of multiple first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com