Hoisting cage for hoisting electromechanical device

A technology for electromechanical equipment and hoisting, which is applied in the directions of transportation and packaging, load hoisting components, etc., to achieve the effect of efficient and safe hoisting and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

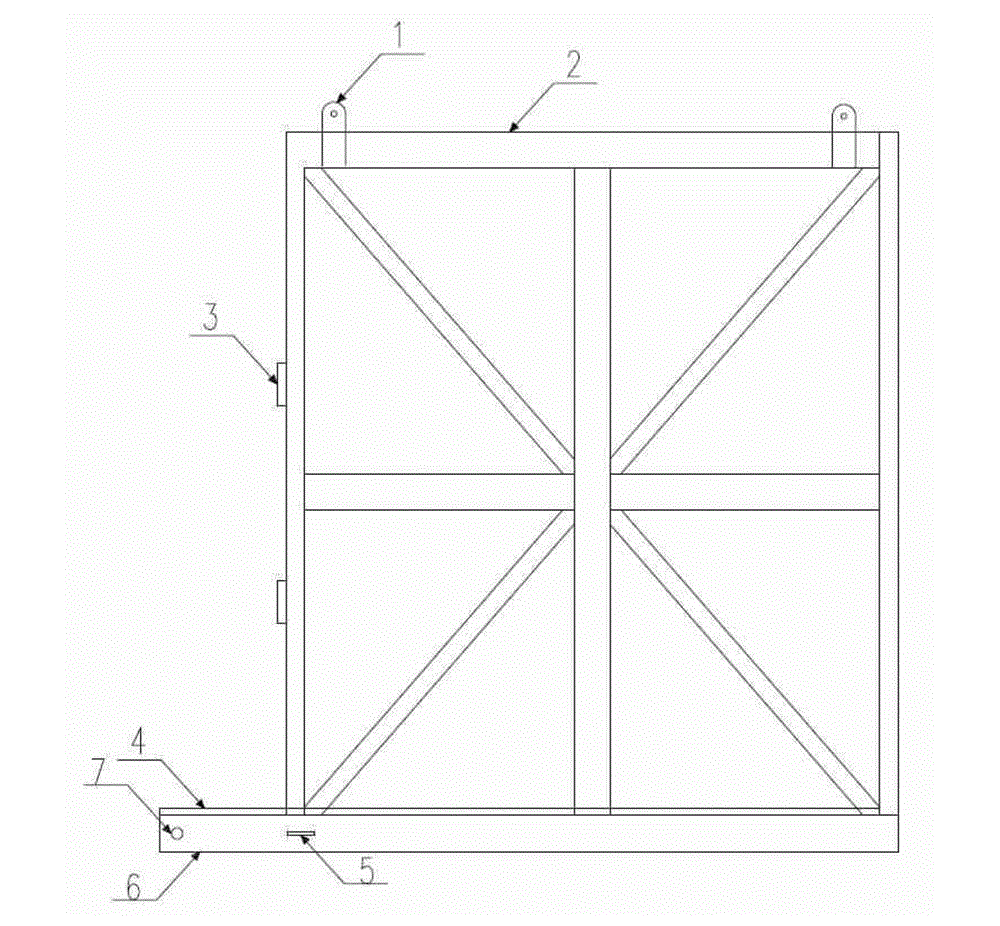

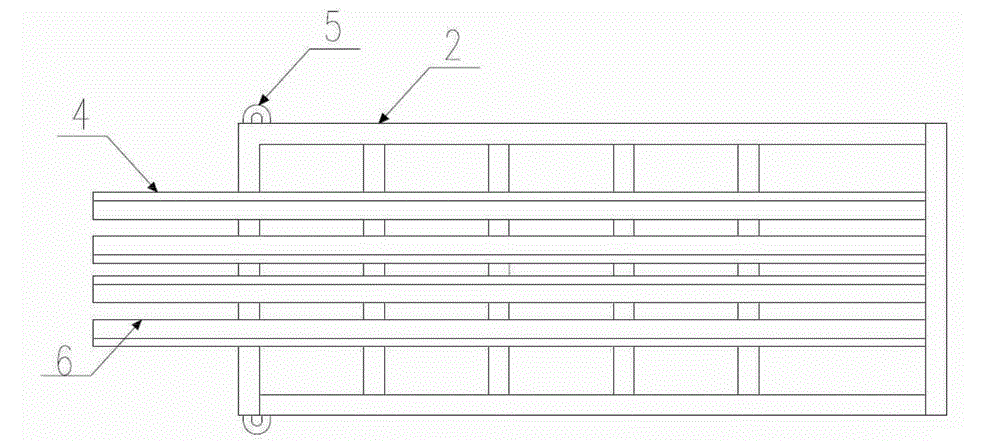

[0017] Structural drawings further describe the present invention.

[0018] Such as figure 1 , figure 2 As shown, the present invention includes four lifting lugs 1, a cage body 2, two guide rails 4, and a base. The front side of the cage body 2 is set as a movable latch door 3, the bottom of the cage body is welded to the base, and the base protrudes from the cage body 2 part on the front side of the cage body 2 to form a base support leg 6, and the base support leg 6 The length is 700mm; two guide rails 4 are welded on the base, and the two guide rails 4 are matched with the ground tank for transportation, an earring 5 is respectively arranged on the left and right sides of the front side of the base, and the front section of the support leg 6 of the base is provided with Hole 7.

[0019] Construction process of the present invention is:

[0020] Firstly, according to the size and weight of the electromechanical equipment, the type steel is selected to make and process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com