An anti-twist structure for a toggle piece of a lock cylinder

A toggle piece and lock cylinder technology, applied in the field of locks, can solve the problems of not being able to ensure the safety of the lock cylinder, the lock cylinder falling off, etc., and achieve the effect of ingenious design, preventing violent unlocking, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

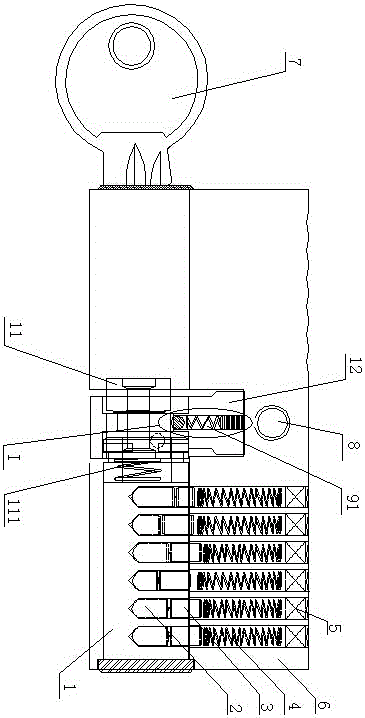

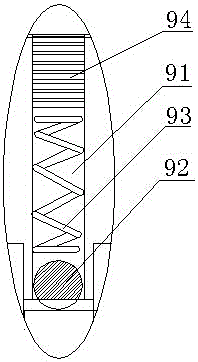

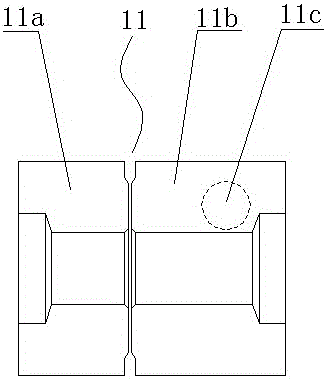

[0026] The title of each reference sign in the accompanying drawings of the present invention is:

[0027] Lock cylinder inner core 1, collar groove 1a, toggle piece groove 1b, lower pin 2, upper pin 3, pin spring 4, door sealing pin 5, lock core body 6, key 7, mounting hole 8, locking hole 91, Steel ball 92, locking spring 93, set screw 94, inner rotor 11, first inner rotor unit 11a, second inner rotor unit 11b, cavity 11c, inner rotor spring 111, toggle unit 12 , bump 12a, widened portion 12b.

[0028] Describe the present invention in further detail below in conjunction with accompanying drawing:

[0029] Such as Figure 1 to Figure 7 as shown,

[0030] An anti-twisting structure of a toggle for a lock cylinder, comprising a toggle 12 installed in a lock cylinder body 6, an inner turning piece 11 and an inner core 1 of the lock cylinder, and a lock is vertically provided on the toggle 12. A stop hole 91, in which a steel ball 92, a lock spring 93 and a set screw 94 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com