Lock head adopting vane spring idle rotation lock master structure and the key thereof

A pincer and blade technology, applied in the field of mechanical locks, can solve the problems of difficult to guarantee machining accuracy, many parts, time-consuming processing, etc., and achieve the effect of improving safety, reducing parts and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

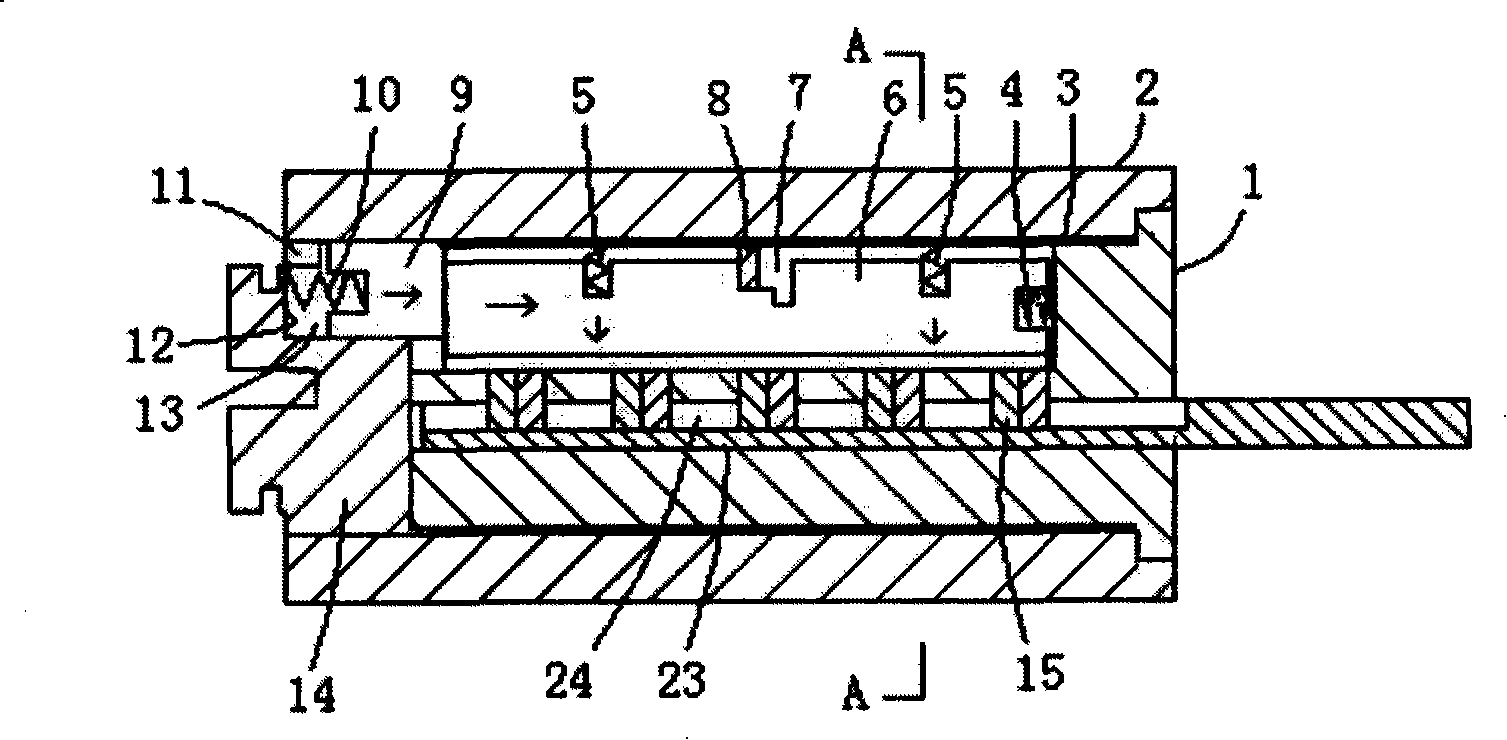

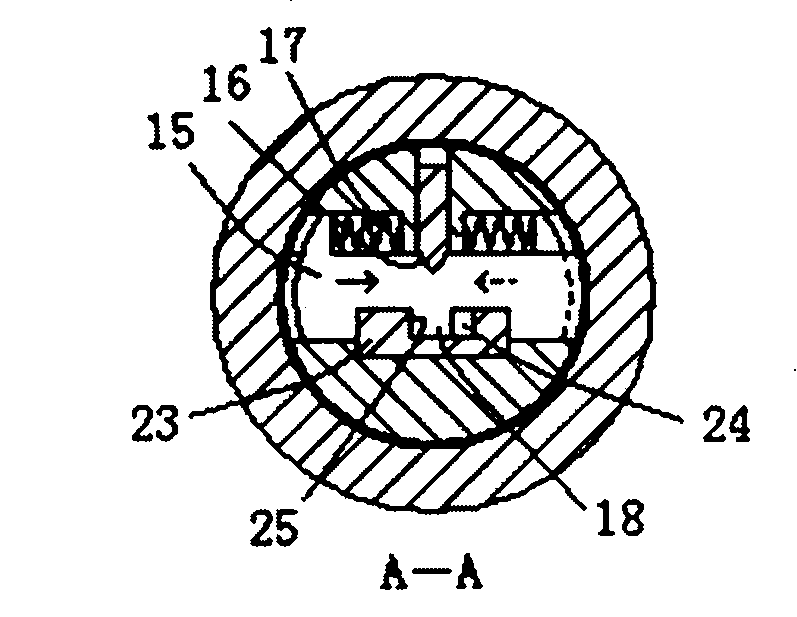

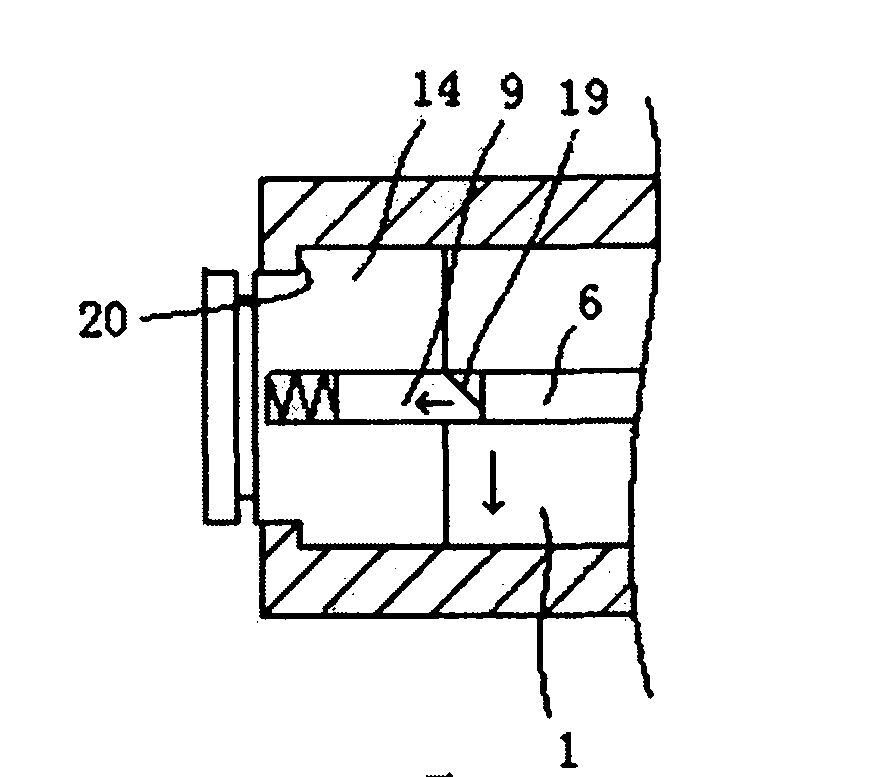

[0019] see Figure 1 to Figure 4 , The lock head of the present invention includes a lock body 2 and a lock cylinder in the lock body 2. The lock cylinder is divided into a front lock cylinder 1 and a rear lock cylinder 14. The front lock cylinder is provided with a number of two-blade marbles 15 along the axis. A set of blade pinballs. The locking side column slot on the front lock cylinder 1 is provided with a locking side column 6 that can be matched with the V-shaped groove 16 on the blade pin, and the locking side column 6 is provided with a stepped groove 7 , The upper part of the locking side column groove is provided with a card 8 and a fixing part that are matched with the step-shaped groove 7 on the locking side column. The fixing part adopts the sleeve 3, the sleeve 3 and the locking side column 6 which are sleeved on the front lock cylinder. A locking side post radial return spring 5 is provided between the locking side post 6 and the locking side post axial return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com