Burglarproof nut and manufacturing method thereof

A technology of anti-theft nuts and nut sleeves, which is applied in the direction of nuts, bolts, threaded fasteners, etc., can solve the problems of complex process, many production processes, and metal waste, and achieve the effect of saving metal materials and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

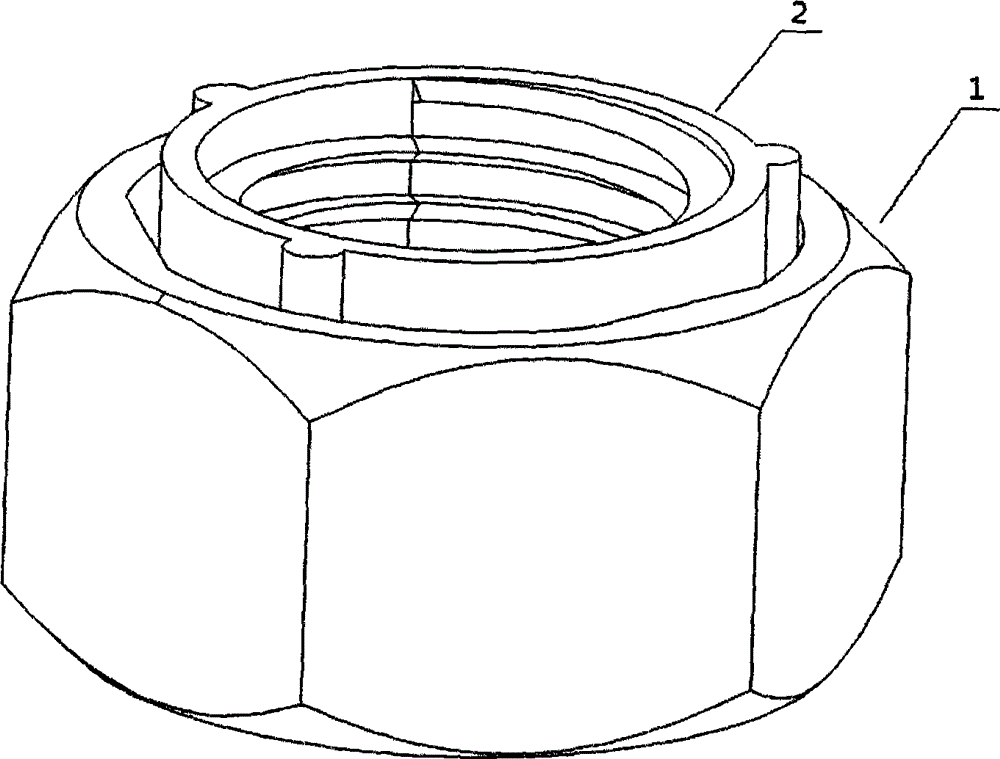

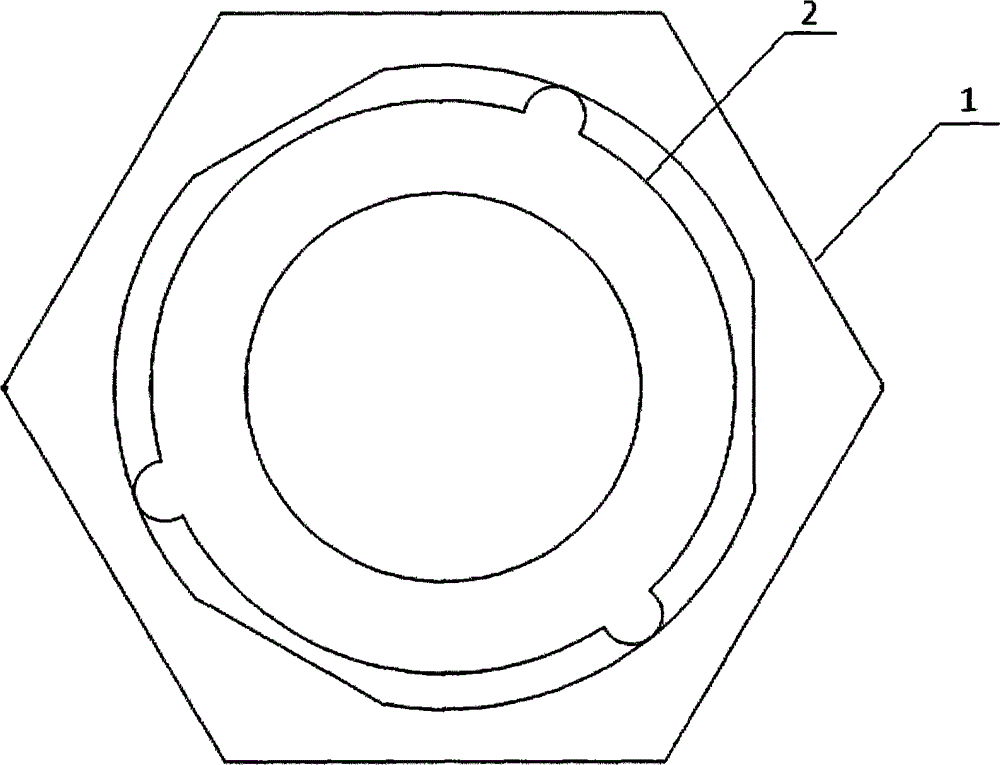

[0040] An anti-theft nut, comprising: a nut cover 1 made of metal material and a fastening body 2 arranged in the nut cover 1, the cross-sectional shape of the outer wall of the nut cover 1 is a regular polygon with more than four sides; the nut cover The middle part of the sleeve 1 is provided with a first groove, and the inner wall of the first groove is provided with at least one plane parallel to or passing through the axis of the nut sleeve 1, or at least one first rib protruding toward the axial direction of the nut sleeve 1 , or at least one plane parallel to or passing through the axis of the nut sleeve 1 and at least one first rib protruding toward the axis of the nut sleeve 1 are provided at the same time; the bottom of the first groove is provided with a first through hole.

[0041] The fastening body 2 is hollow cylindrical, the middle part of the fastening body 2 is provided with a circular second through hole, and the outer wall of the fastening body 2 is provided w...

Embodiment 2

[0055] Such as figure 1 and figure 2 As shown, compared with Example 1, the only difference is that the inner side walls of the first groove of the nut sleeve 1 are spaced 120° apart from each other, and three planes parallel to the axis are arranged, and the outer side walls of the fastening body 2 are spaced 120° apart from each other. ° There are three second corrugations with semicircular cross-sections. When the anti-theft nut 1 is rotated and tightened, the plane of the inner wall of the nut sleeve 1 abuts against and squeezes the second rib on the outer wall of the fastening body 2, causing the thread of the fastening body 2 to be damaged to a certain extent. , the nut sleeve 1 slips relative to the fastening body 2 and rotates in the circumferential direction, so the fastening body 2 cannot be removed.

Embodiment 3

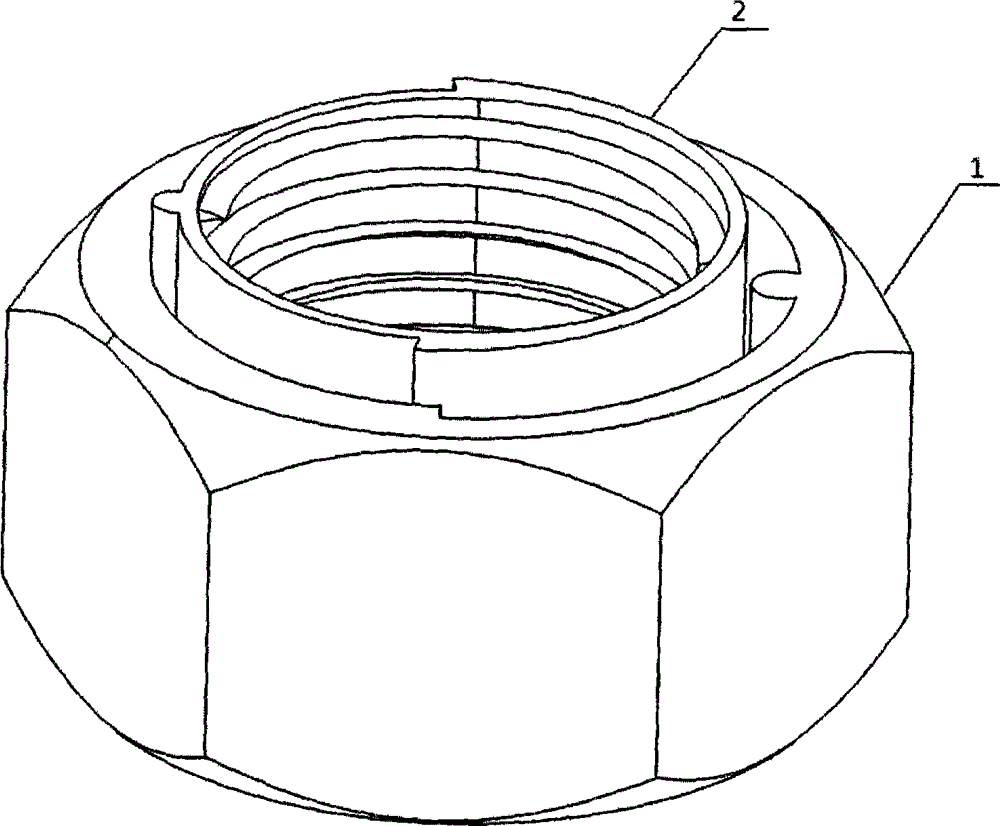

[0057] Such as image 3 and Figure 4 As shown, compared with Example 1, the only difference is that the axes of the nut sleeve 1 and the fastening body 2 are not coincident but parallel, and the inner wall of the nut sleeve 1 is composed of an arc surface with a larger diameter and a smaller diameter. The circular arc surface is formed by connecting two small planes, and the larger arc surface is provided with a corrugation; the outer wall of the fastening body 2 is composed of an arc surface with a larger diameter and an arc surface with a smaller diameter. It is formed by connecting two small planes, and the smaller arc surface is provided with a rib; the smaller arc surface of the inner wall of the nut sleeve 1 is connected to the larger arc surface end of the fastening body 2 part, the ribs on the inner side wall of the nut sleeve 1 are in contact with the larger arc surface of the fastening body 2, and the ribs on the outer side wall of the fastening body 2 are in conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com