Grinding device

A technology for grinding and grinding surfaces, applied in abrasive surface adjustment devices, parts of grinding machine tools, grinding/polishing equipment, etc., can solve the problem of fast consumption of dressing plates, and achieve the effect of prolonging replacement intervals and suppressing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

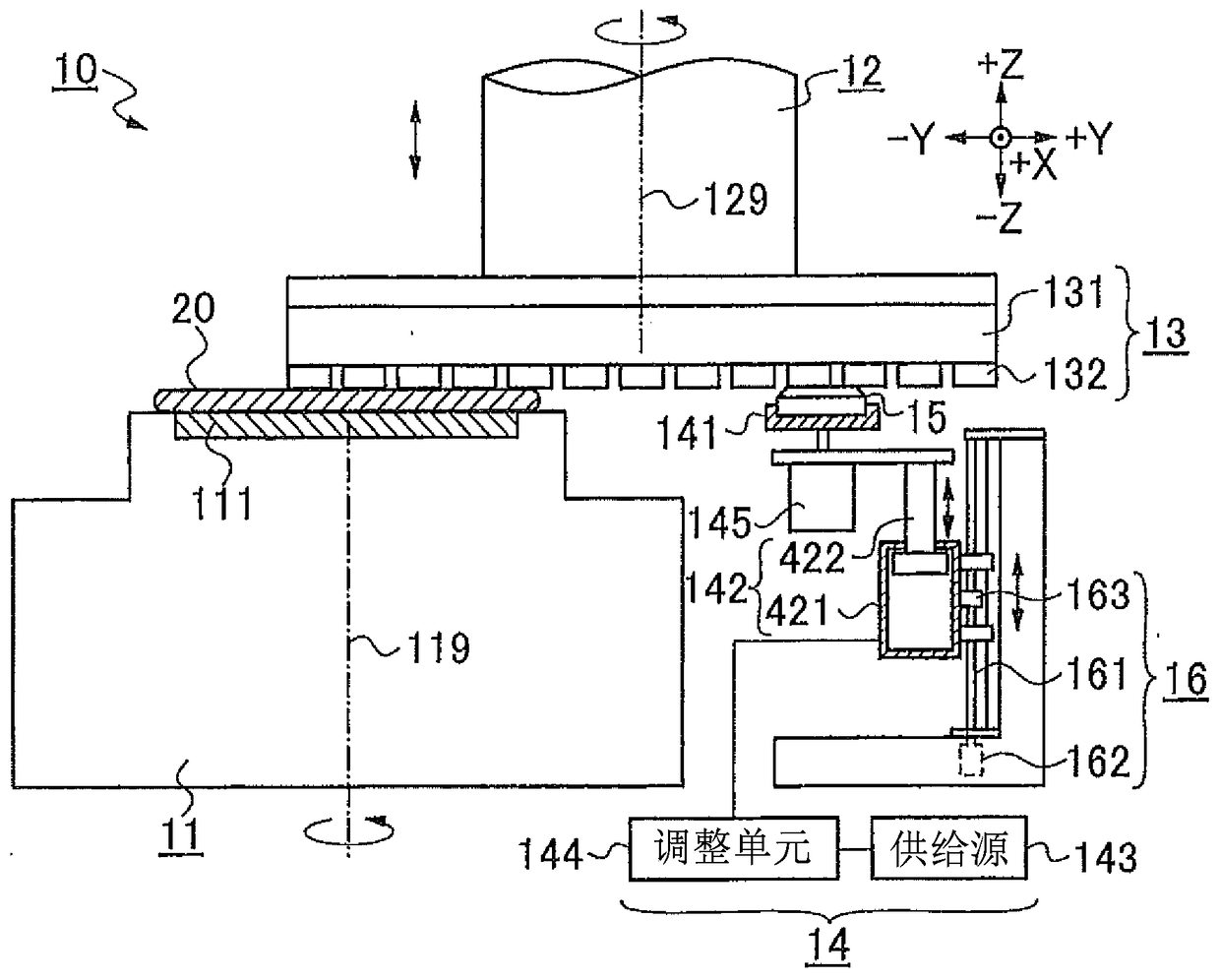

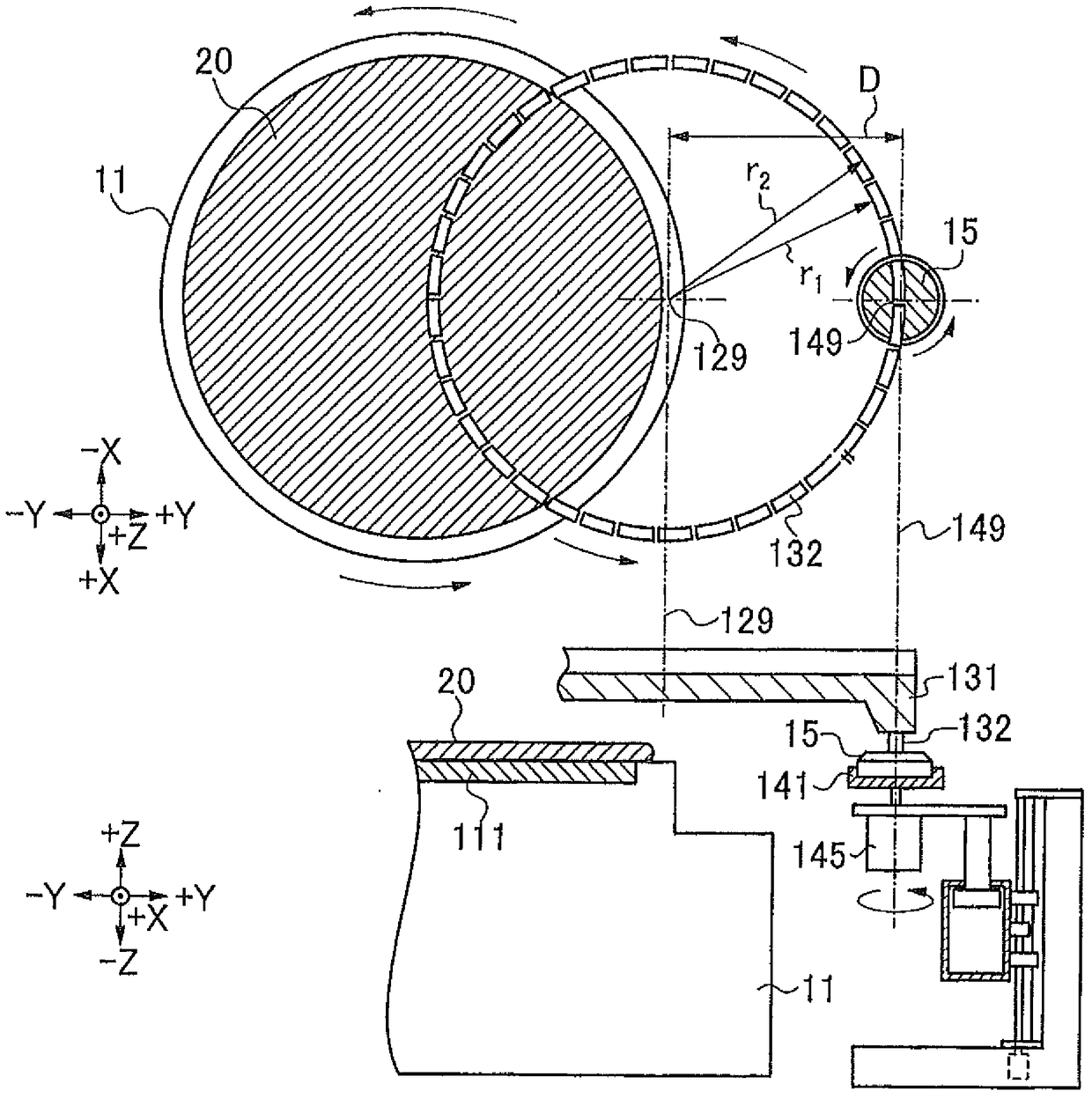

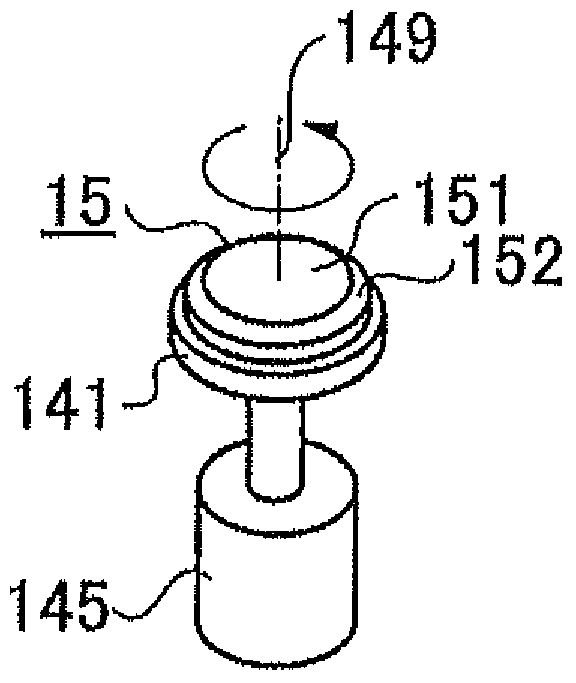

[0026] figure 1 The shown grinding device 10 has a chuck table 11 holding a workpiece 20, a grinding unit 12 for grinding the workpiece 20 held on the chuck table 11, and the grinding unit 12 is positioned in the ±Z direction. Grinding feed unit (not shown) moving on (grinding feed direction). The grinding feed unit brings the grinding unit 12 close to the chuck table 11 by moving the grinding unit 12 in the −Z direction, or moves the grinding unit 12 away from the chuck table 11 by moving the grinding unit 12 in the +Z direction.

[0027] The chuck table 11 has a holding surface 111 formed of a porous material or the like, and rotates about a rotation axis 119 parallel to the ±Z direction. The workpiece 20 is placed on the holding surface 111 perpendicular to the ±Z direction, and is sucked by a suction source (not shown), thereby sucking and holding the workpiece 20 . The workpiece 20 held on the holding surface 111 rotates around the rotation shaft 119 as the chuck table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com