Permanent magnetic transmission coupler of wind generating set and generator rotor temperature measuring method

A technology for wind power generators and generator rotors, which can be applied to thermometers, measuring devices, and heat measurement, etc., and can solve problems such as no measurement methods for rotors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

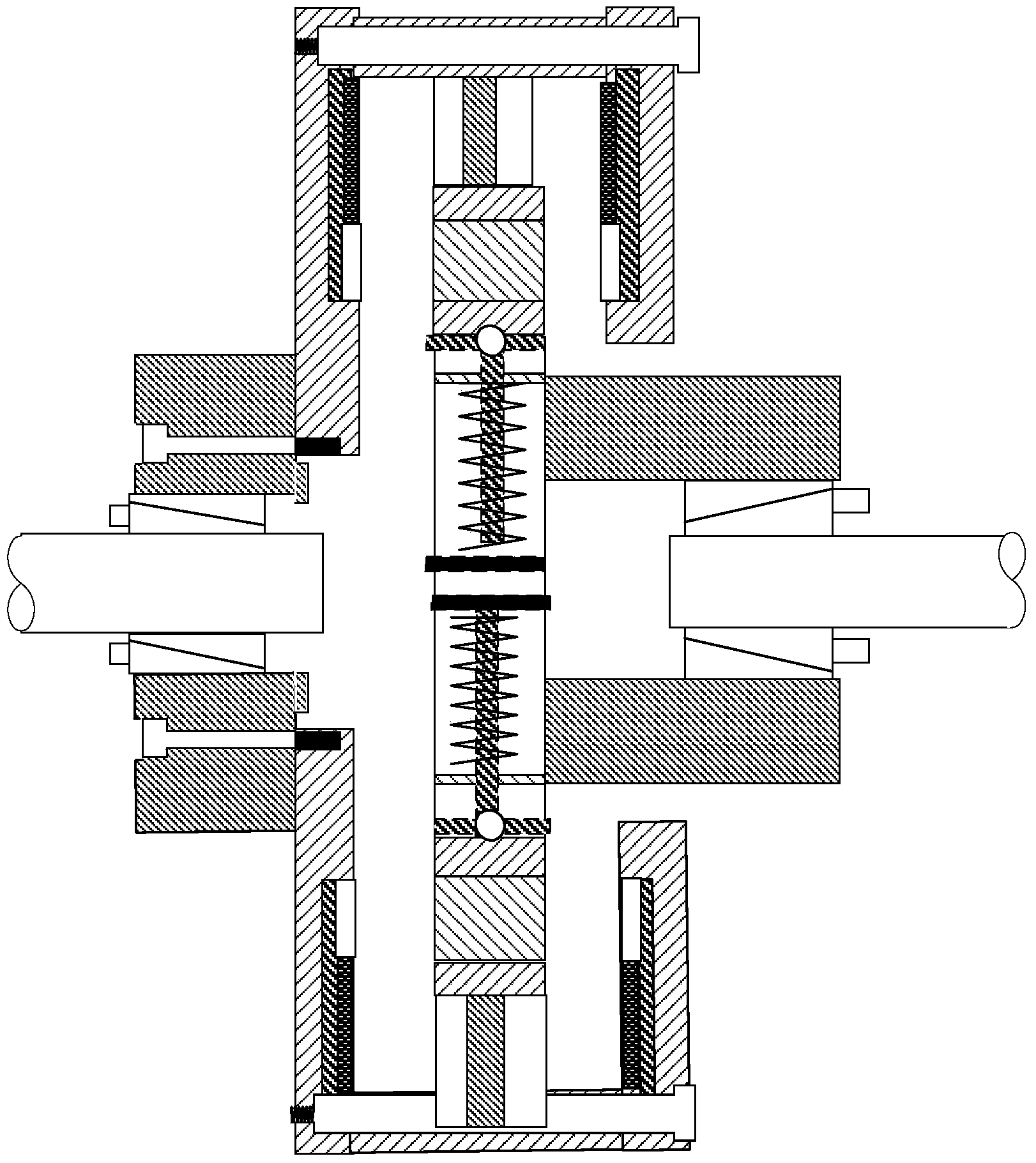

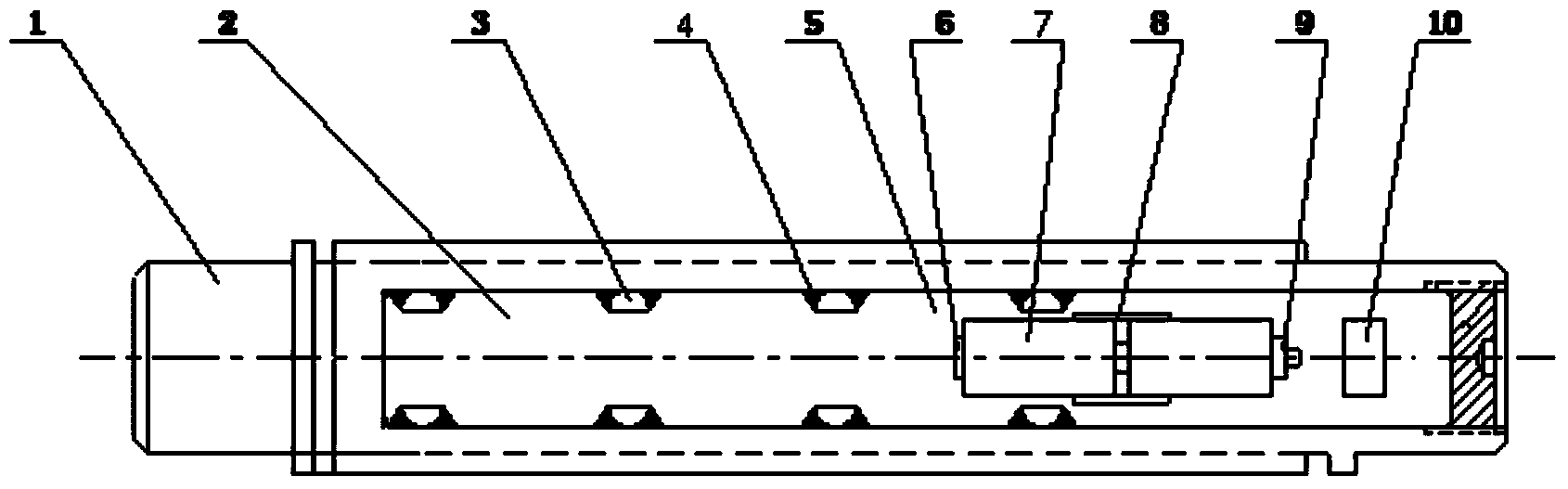

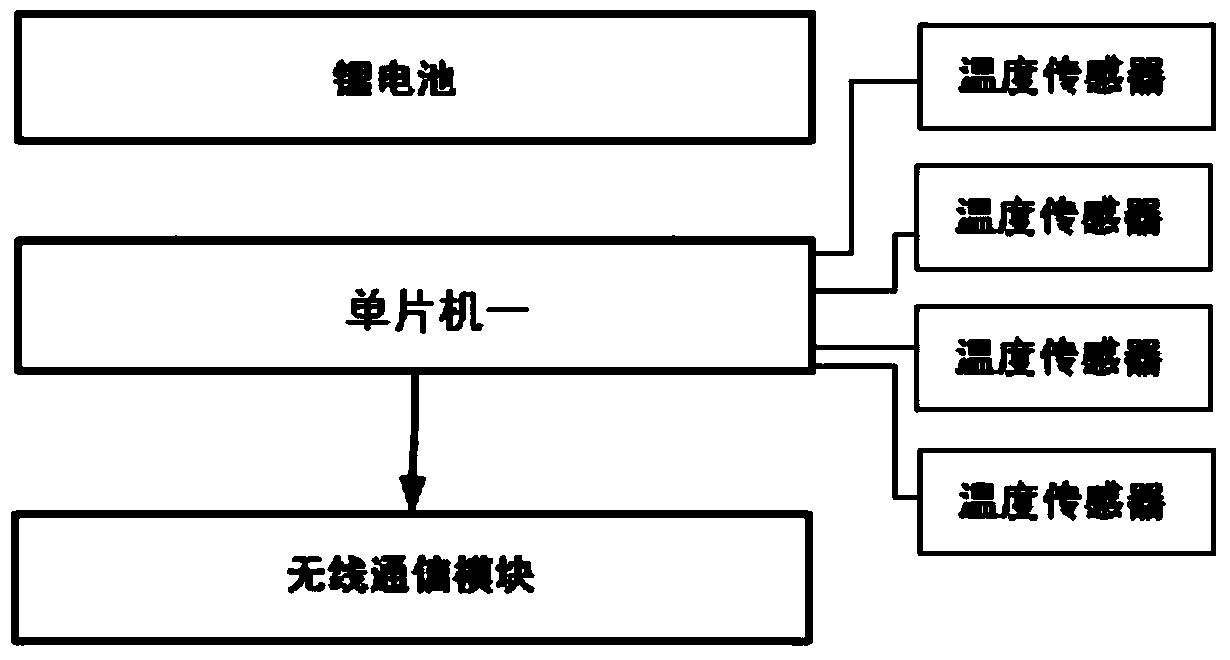

[0017] Wind turbine permanent magnet transmission coupling and generator rotor temperature measurement method, such as figure 1 , figure 2 As shown, the shaft coupling drive shaft of the permanent magnet transmission mechanism and the generator rotor 1 are hollow shafts, and a wireless temperature collector is arranged inside the hollow shaft, and the wireless temperature collector is installed on the coupling and the generator It consists of temperature sensors at multiple temperature measuring points inside the rotor, a single-chip microcomputer (STM32F407ZGT6) controlling multiple temperature sensors, and a wireless communication module (radio frequency chip CC2420), powered by a lithium battery ( image 3 ), the wireless temperature collector wirelessly sends the collected temperature data to the data receiving uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com