A material testing machine

A material testing machine and material testing technology, applied in the direction of analyzing materials, instruments, measuring devices, etc., can solve the problems of test piece damage, splashing, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

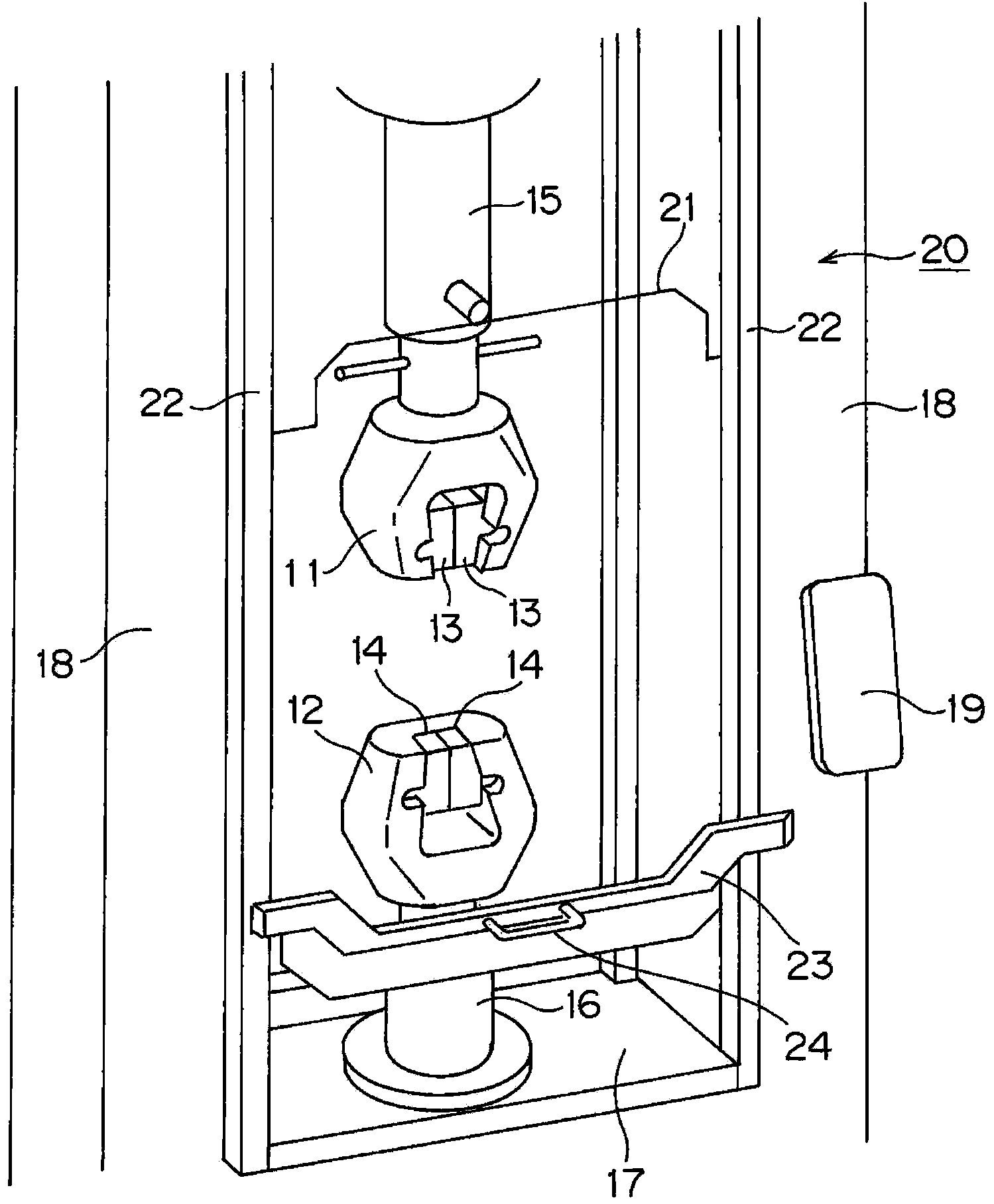

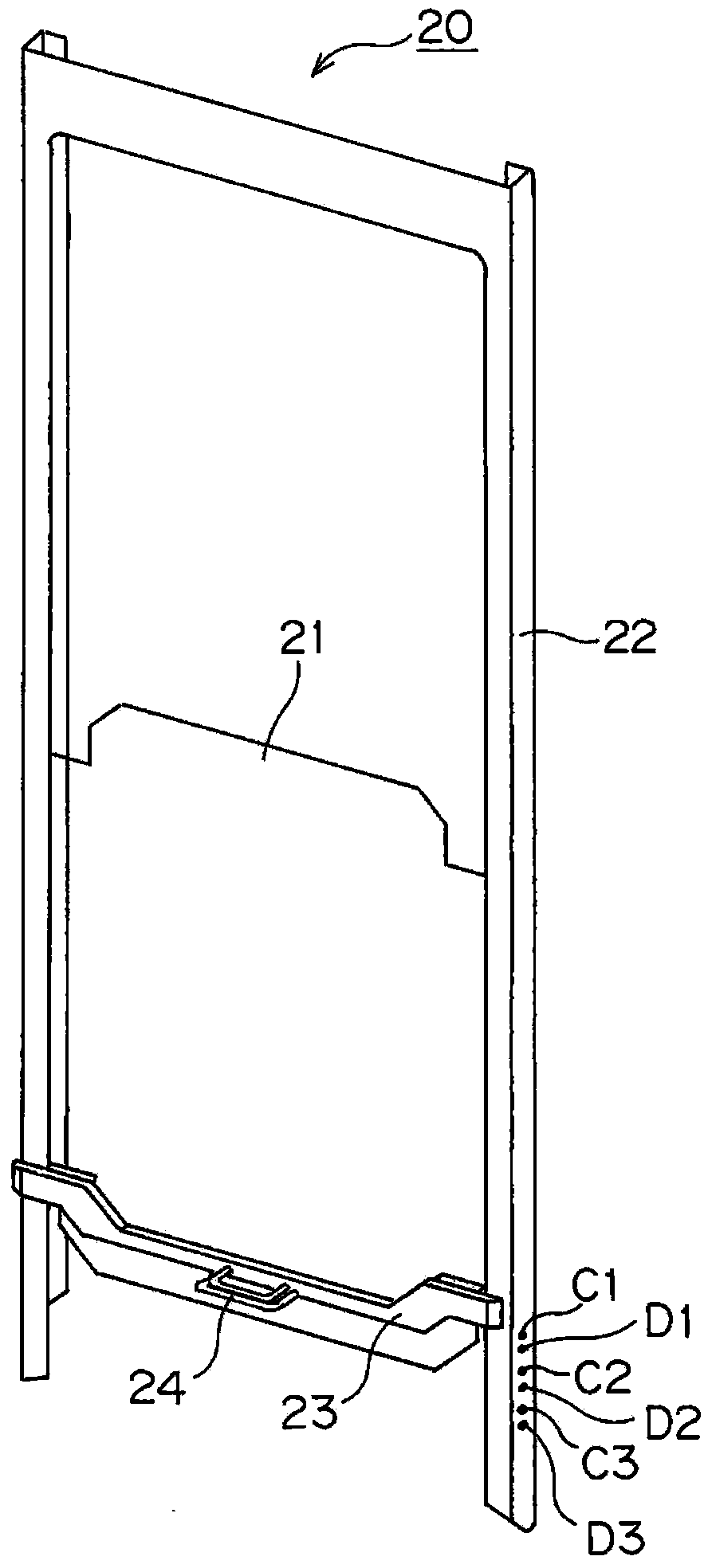

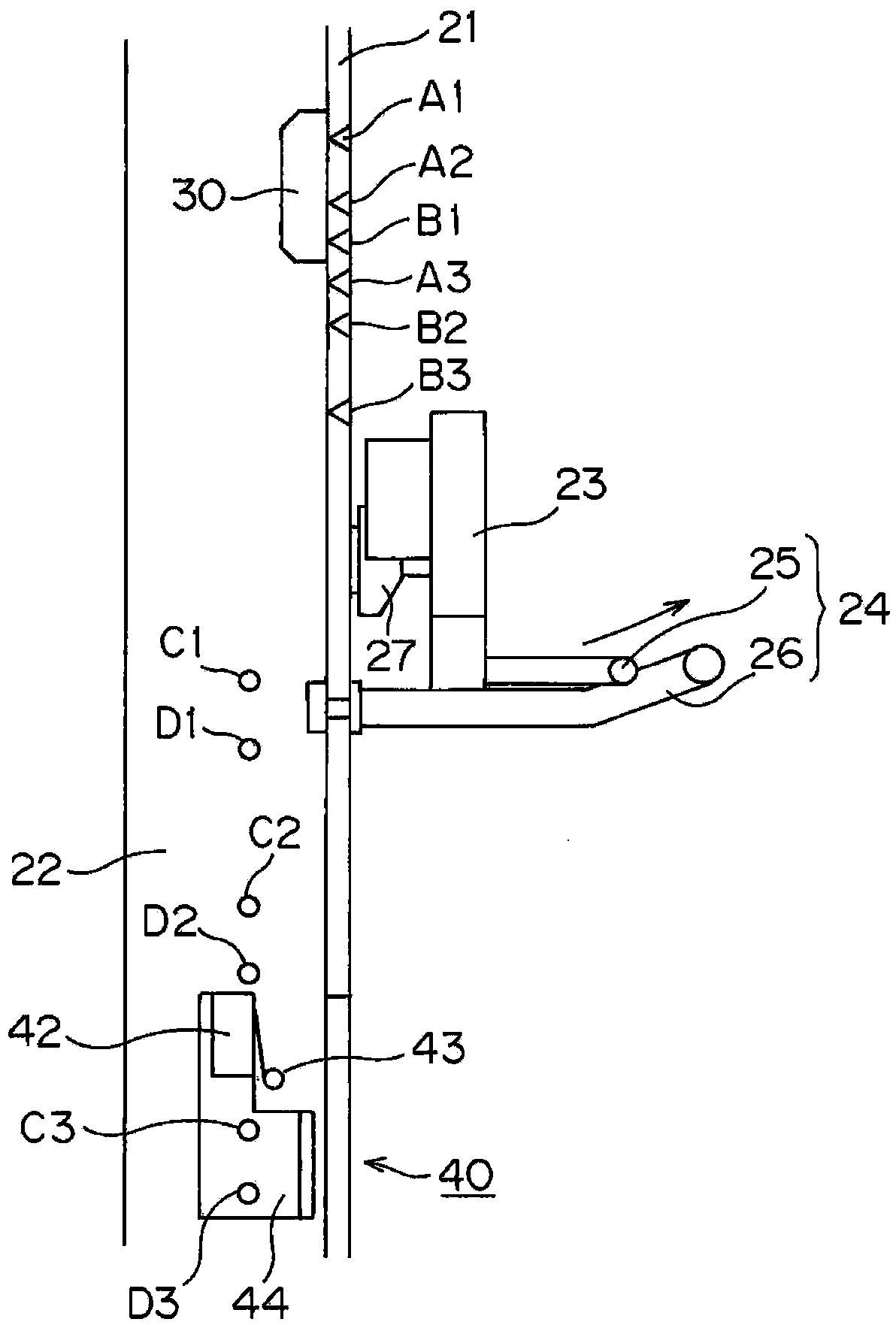

[0030] Embodiments of the present invention will be described below based on the drawings. figure 1 A perspective view showing key parts of the material testing machine involved in the present invention.

[0031] This material testing machine has a pair of columns 18 erected on a table 17 , and a crosshead (not shown) that moves up and down along the columns 18 by driving a screw disposed inside the columns 18 . An upper jig 11 having a pair of gripping teeth 13 for gripping the upper end of the test piece is disposed on the crosshead through a coupling 15 . On the other hand, a lower jig 12 having a pair of gripping teeth 14 for gripping the lower end of the test piece is disposed on the table via a coupling 16 .

[0032] In this material testing machine, when performing a tensile test on a test piece, the input unit 19 inputs necessary test conditions and the like. Then, in a state where both ends of the test piece are held by the upper jig 11 and the lower jig 12 , the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com