Footstand adjusting and positioning structure of magnifying lens device

A technology of positioning structure and magnifying glass, applied in magnifying glass, optics, instruments and other directions, can solve the problems of breakage and damage of the clamping block 251, easy shaking of the foot seat 24, and shortening of service life, etc., to achieve the effect of improving the convenience of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]In order to make your examiner further understand the present invention, hereby give a preferred embodiment and cooperate with the drawings, as follows in detail:

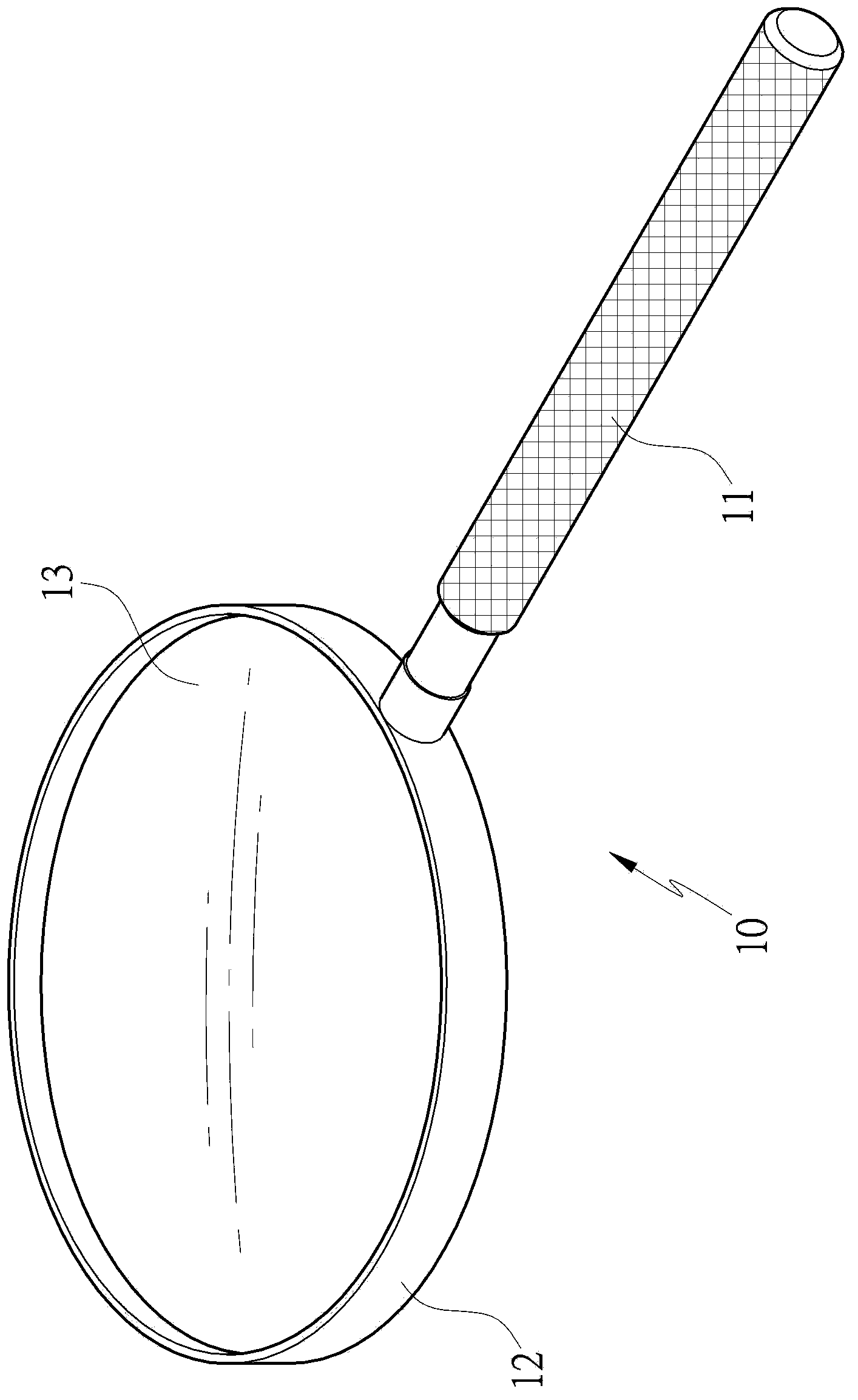

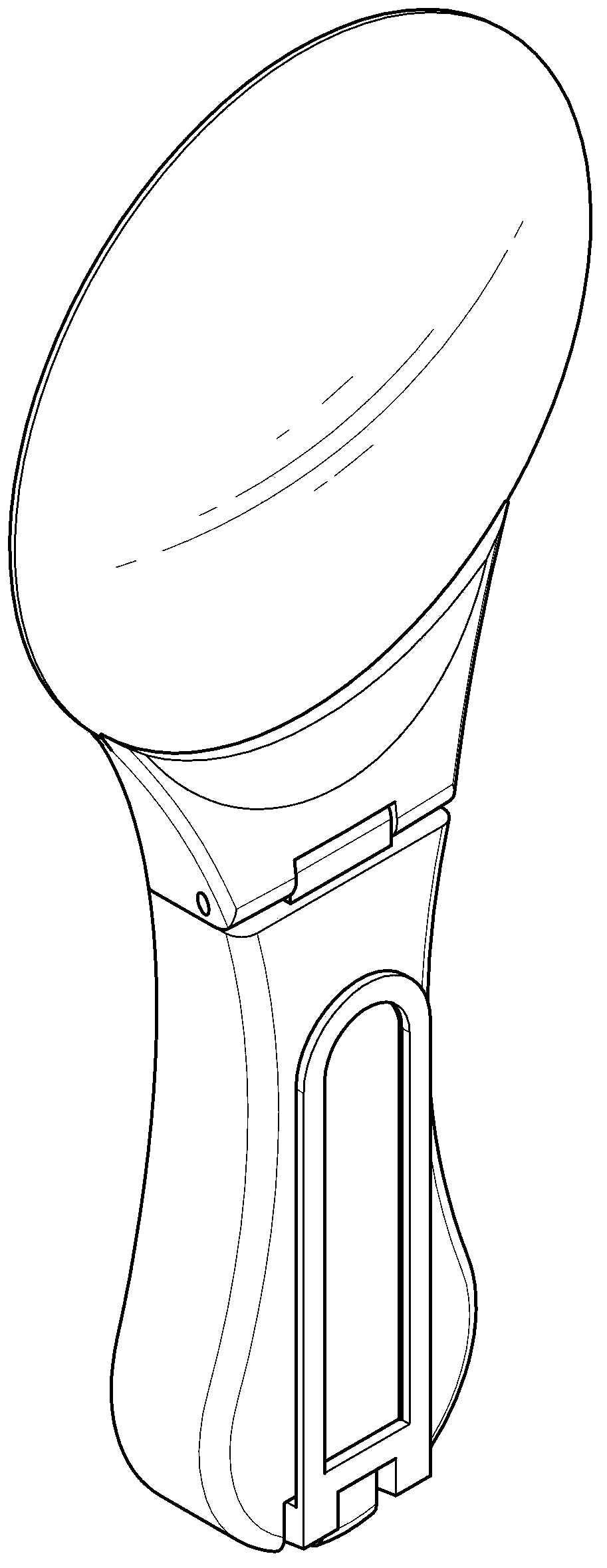

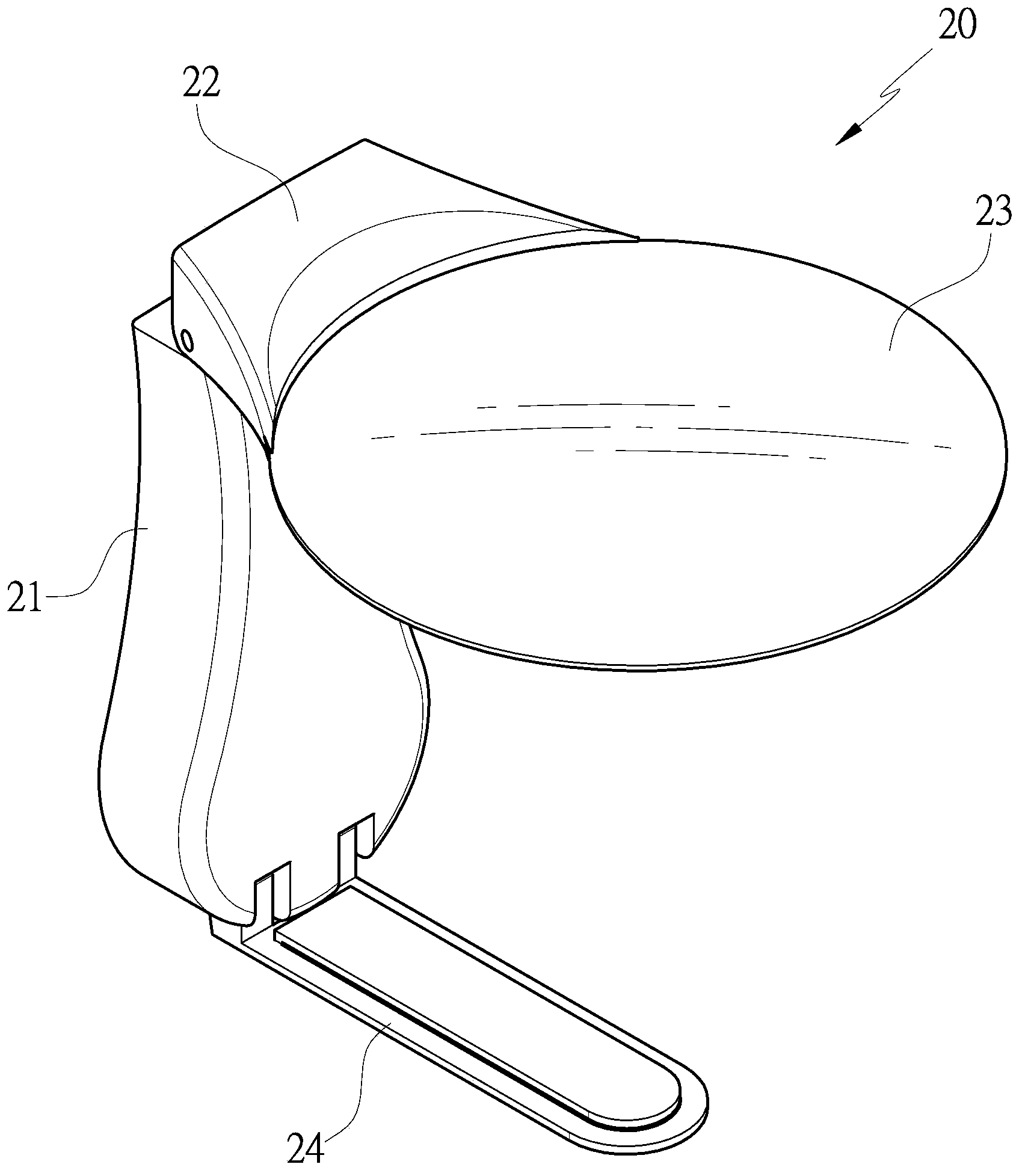

[0047] see Figure 5 , Image 6 , Figure 7 As shown, the magnifying glass device 30 of the present invention includes a grip body 31, a bearing seat 32, a foot seat 33 and a positioning member 34; one end of the grip body 31 is connected with a shaft 311 to pivotally set the bearing seat 32, So that the bearing seat 32 can swing and displace along the shaft 311, a mirror frame 321 is provided on the bearing seat 32 for installing the lens 322; one end of the foot base 33 is provided with a pivot joint 331 for The connection is pivotally arranged at the other end of the grip body 31, and a top catch portion 332 is provided on the outer surface of the pivot portion 331; in this embodiment, the other end of the grip body 31 and the The pivot joints 331 of the feet 33 are respectively provided with shaft hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com