Water-cooled proton exchange membrane fuel cell stack and water-cooled proton exchange membrane fuel cell

A fuel cell stack and proton exchange membrane technology, applied in the field of water-cooled proton exchange membrane fuel cell stack and water-cooled proton exchange membrane fuel cell, can solve the problems of easy accumulation of water, instability, poor gas concentration, etc., and achieve gas distribution The effect of uniform, stable operation and smooth drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The water-cooled proton exchange membrane fuel cell stack assembly of the present invention will be described below by way of example with reference to the accompanying drawings. However, it should be understood that the following embodiments and drawings are illustrative only and do not limit the scope of the present invention. The scope of the invention should be defined by the appended claims. Also, for the sake of clarity, the figures are not drawn to scale.

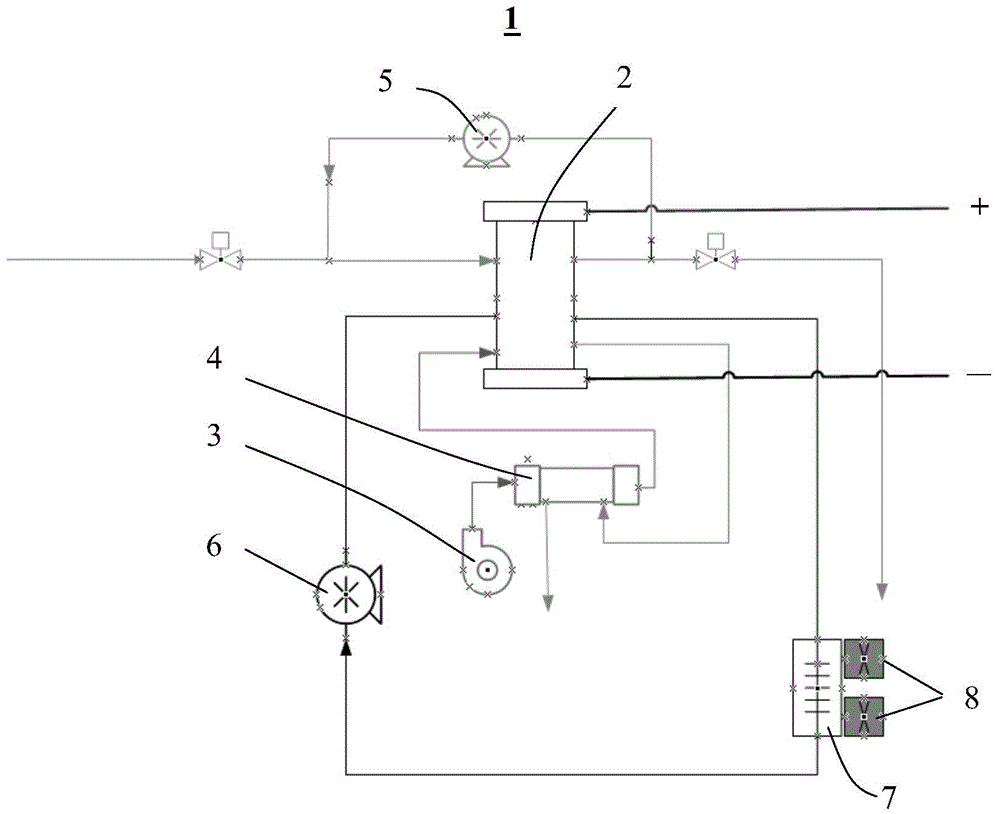

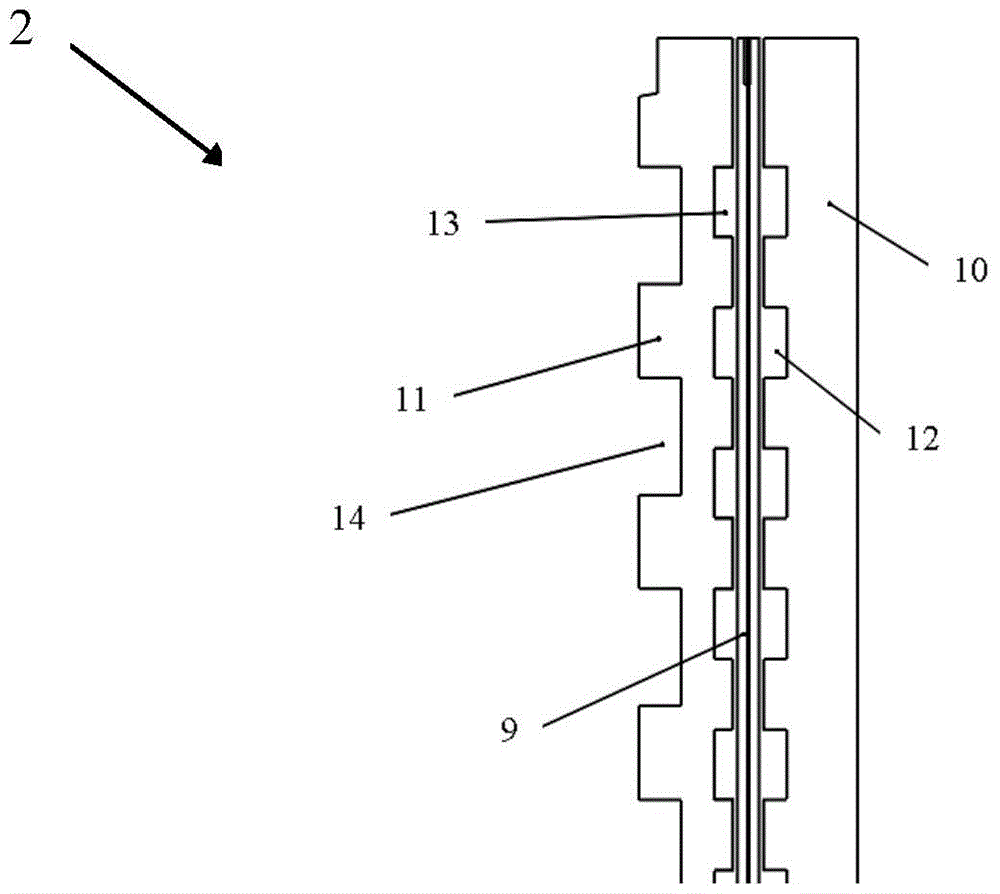

[0046] The water-cooled proton exchange membrane fuel cell stack 100 of the present invention includes a cathode flow field 20 , an anode flow field 30 and a cooling flow field 40 .

[0047] Cathode flow field

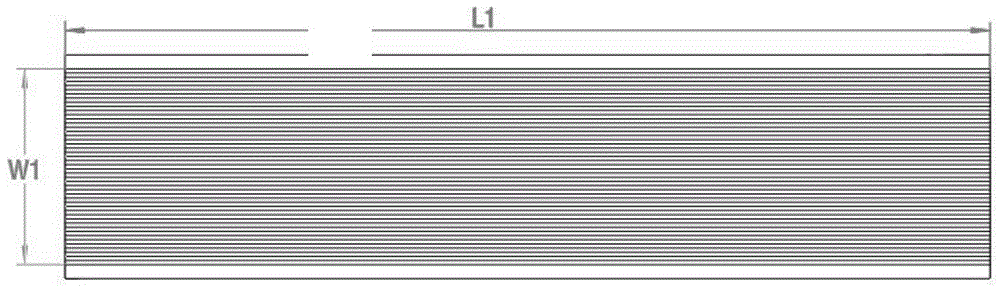

[0048] image 3 A schematic diagram of the cathode flow field of the water-cooled proton exchange membrane fuel cell stack of the present invention is shown. Figure 4 show image 3 A partial perspective view of the flow channels of the cathode flow field.

[0049] Such as image 3 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com