Monitoring system and method for cigarette machine consumables

A technology for cigarette making machines and consumables, applied in computer components, instruments, data processing applications, etc., can solve problems such as product quality accidents, mismatches, and wrong shipments, and achieve precise control of product quality, accurate inventory management of auxiliary materials, and improved management horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

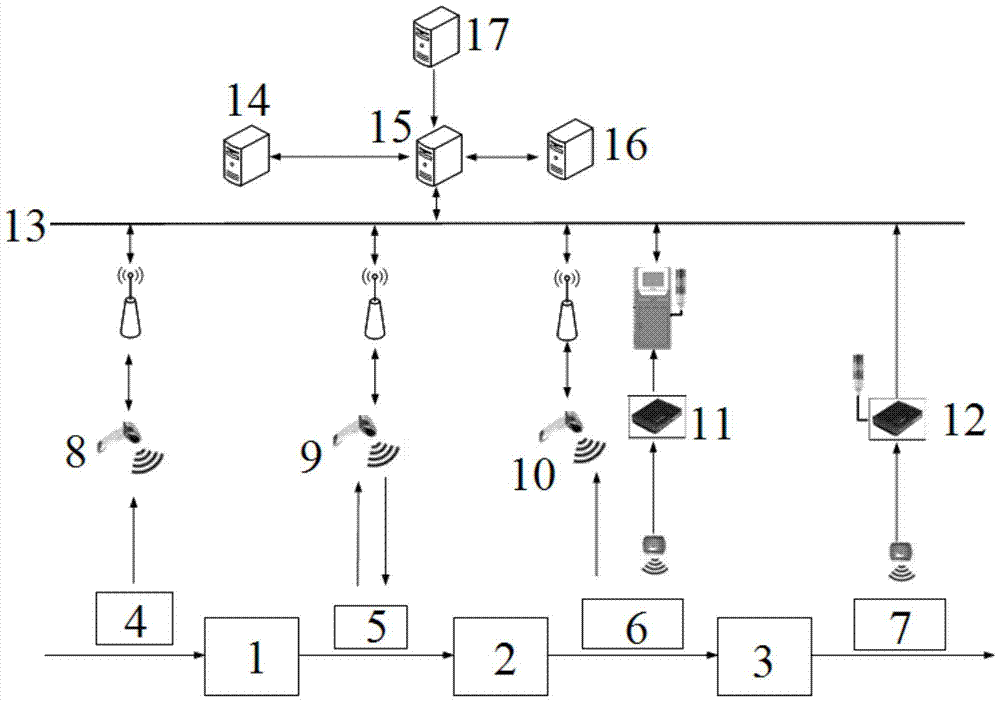

[0028] A cigarette machine consumables monitoring system, such as figure 1 As shown, include: server 15, handheld PDA reader-writer (8,9,10), the automatic RFID reader-writer 11 that is arranged on the transfer storehouse 2 outbound places and the automatic RFID reader-writer 12 that every cigarette machine is provided with, Each reader / writer is connected to the server 15 through the network 13 to complete the data collection of each link of the cigarette consumables; Both the warehouse and the on-site terminal cabinet of the machine are provided with alarm indicator lights, and the alarm indicator lights are all connected to the server 15. The server 15 is respectively connected with the data acquisition system 14, the budget management system 16 of the cigarette manufacturer, and the auxiliary material information system 17 of the auxiliary material supplier; figure 1 The serial number 3 represents the workshop.

[0029] As the medium of the cigarette machine consumables ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com