Cartridge case machining process

A processing technology and cartridge case technology, which is applied in the field of cartridge case processing technology, can solve the problems of complicated cartridge case processing technology and difficulty in ensuring accuracy, and achieve the effect of reducing working time and workload and ensuring the accuracy of cartridge cases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

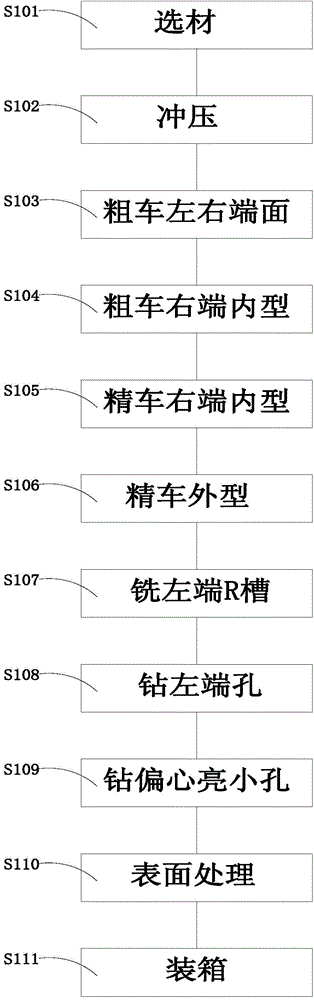

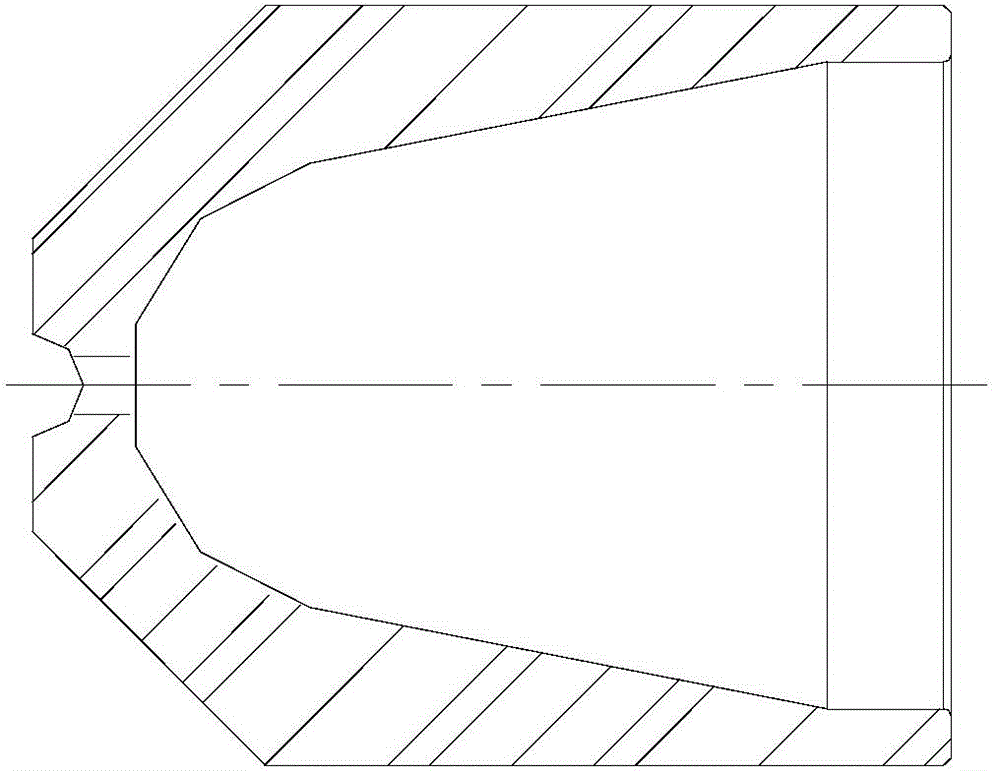

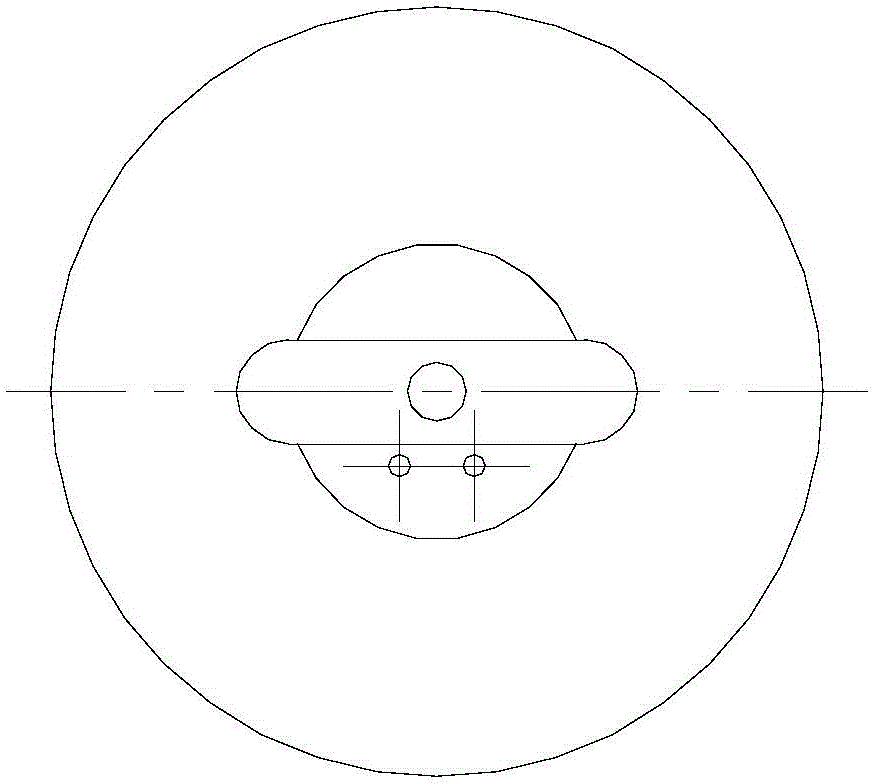

[0031] Such as figure 1 — image 3 Shown, a kind of cartridge case processing technology comprises the following steps:

[0032] Step S101, material selection: select materials of 680g-685g / piece;

[0033] Step S102, stamping: stamping the cartridge case to form, the total length of the formed cartridge case is 66±0.5mm, and the coaxiality between the formed cartridge case inner cavity and the outer shell is 0.5mm;

[0034] Step S103, roughing the left and right end faces: roughing the right end face of the cartridge case, the total length after roughing the right end face is The perpendicularity between the shell and the right end face of the rough-turned right end face is 0.15mm, the left end face of the rough-turned cartridge case, and the total length behind the rough-turned left end face is The surface roughness of the cartridge case is 12.5μm;

[0035] Step S104, the inner shape of the right end of the rough car: the drilling depth is The inner cavity at the ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com