Automatic force application device for adjusting back pulling rod of miter gate

A technology of miter gates and booster devices, which is applied to ship lifting devices, ship locks, water conservancy projects, etc. It can solve the problems of long construction period, high labor intensity, complicated process, etc., and achieves convenient operation, high safety and friendly interface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

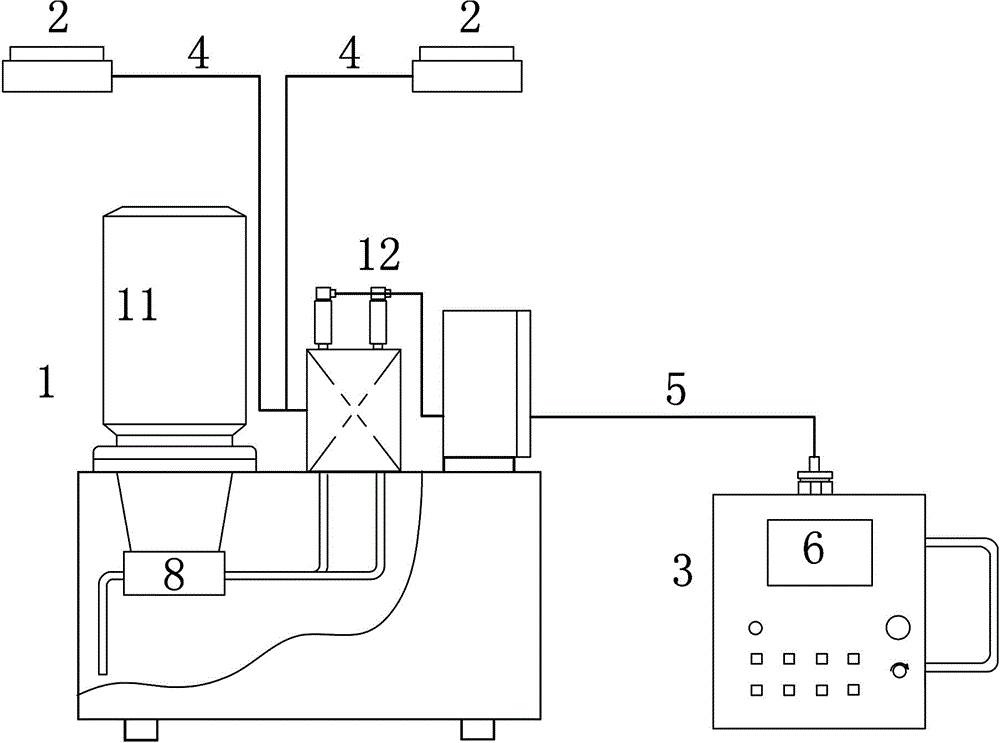

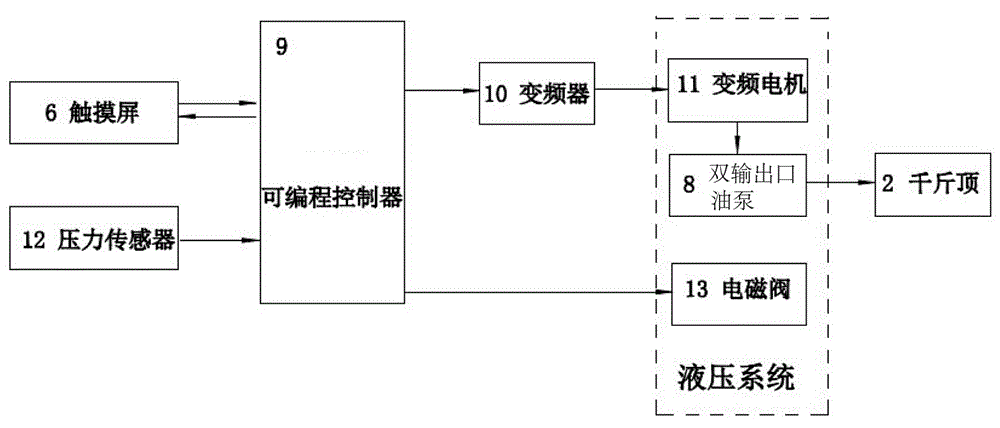

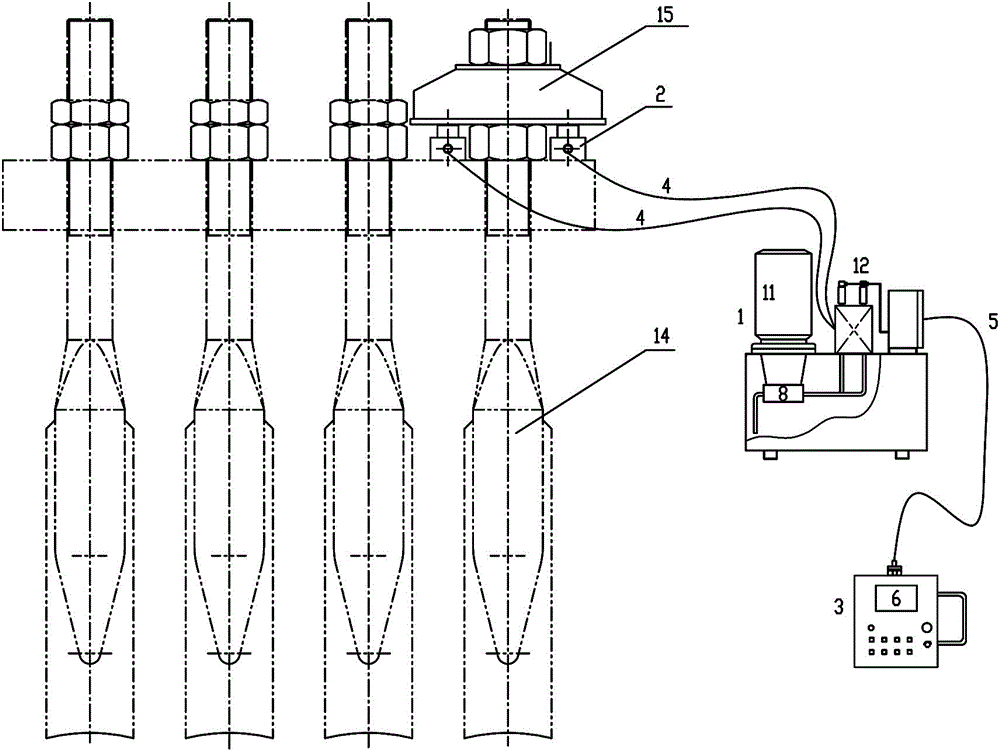

[0019] The structure of the present invention is as figure 1 , 3 Shown: an automatic booster device for adjusting the back pull rod of the herringbone gate, the device includes a hydraulic pump station 1, a jack 2 and a portable control box 3, and the jack 2 is connected with the hydraulic pump station 1 through a hydraulic hose 4 , the portable control box 3 is connected with the hydraulic pump station 1 through the cable 5; the hydraulic pump station 1 includes a dual-output oil pump 8 and a pressure sensor 12; the portable control box 3 includes a programmable controller 9, which is programmable The controller 9 is connected with the operation touch screen 6 and the frequency converter 10 through signal lines, and is respectively connected with the output ports of the dual-output oil pump 8 .

[0020] In the present invention, there are two jacks 2, which are respectively connected with the two output ports of the dual-output oil pump 8, and the jacks 2 are thin jacks.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com