Mechanical vibration damping device for height-limited positioning

A vibration damping device and mechanical technology, applied in the direction of transportation and packaging, substructure, vehicle parts, etc., can solve problems such as uneven transportation and damage to transported goods, and achieve the effect of reducing vibration and enhancing practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

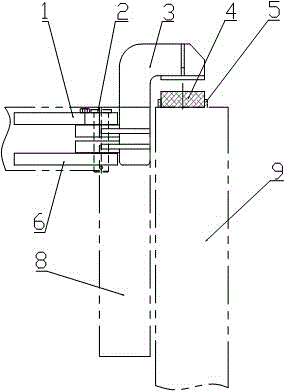

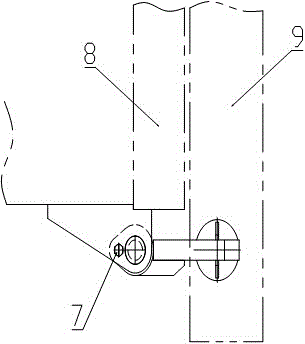

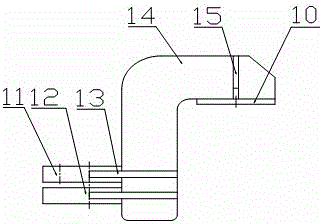

[0029] see figure 1 — figure 2 , the present invention relates to a mechanical damping device for height-limited positioning, which is composed of a rotating platen assembly welding 3, a base hole plate, a pin shaft 2, a circular nylon plate 4, and a nylon plate limit ring 5, the base The orifice plate is divided into an upper base orifice plate 1 and a lower base orifice plate 6. There is a gap between the upper base orifice plate 1 and the lower base orifice 6, and they are welded on the rear frame 8 respectively. The welding 3 is placed in the gap between the upper base orifice 1 and the lower base orifice 6, and is connected with the base orifice through the pin 2, and the nylon plate spacer ring 5 is placed on the top of the middle frame 9 and The corresponding position when the rotating pressure plate welding 3 plays the role of height limit positioning, and welded on the middle frame 9, the circular nylon plate 4 is placed inside the nylon plate limit ring 5, and glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com