Composite movement mechanism

A compound motion, consistent technology, applied in mechanical equipment, transmission, belt/chain/gear and other directions, can solve the problems of difficult to achieve a variety of motion states, difficult to change, complex structure, etc., to achieve simple structure and diverse motion states. , control simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

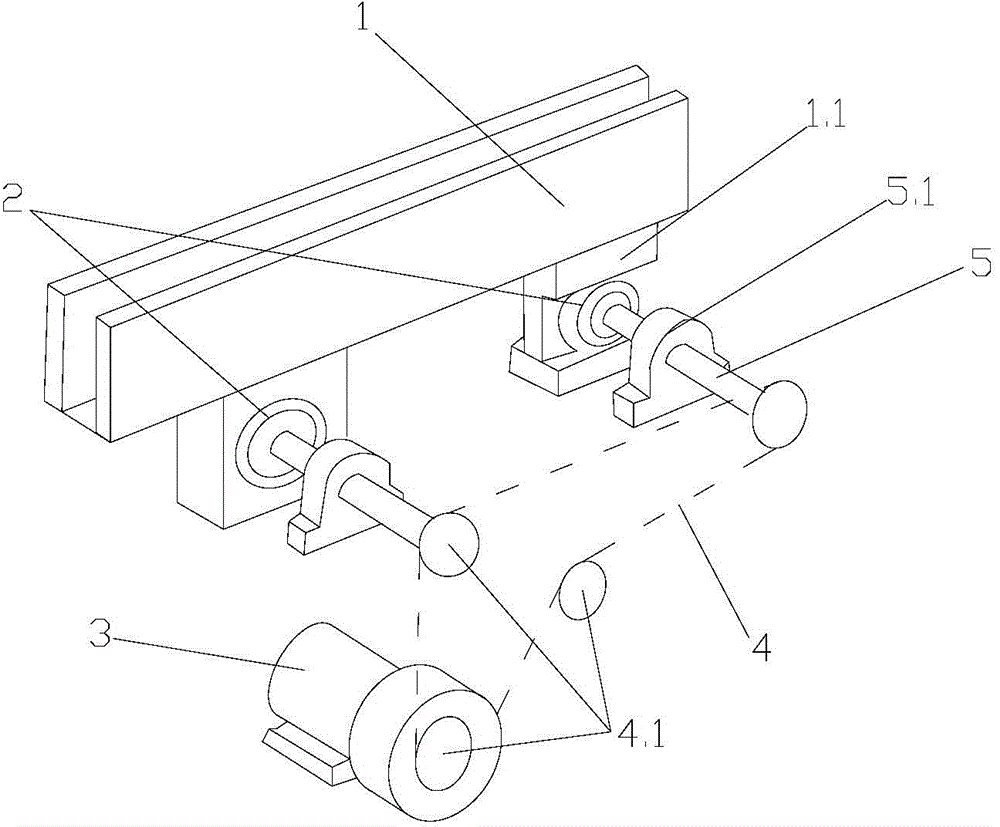

[0011] Example 1: Reference figure 1 , A compound motion mechanism, including straight slot type hopper 1, cam 2, motor 3, and transmission assembly. The number of cams 2 is two, which are correspondingly arranged at the bottom ends of hopper 1. The transmission assembly includes chain 4 and several sprockets. 4.1. The drive shaft 5 connected with the sprocket 4.1. One end of the drive shaft 5 is connected with the sprocket 4.1, and the other end extends to the bottom of the hopper 1 to connect with a fixed cam 2. The bottom of the hopper 1 is provided with a cam seat 1.1 that matches with the cam 2. The cam seat 1.1 There is a cam cavity, the cam 2 is set in the cam cavity, the drive shaft 5 is supported and fixed by the fixing base 5.1, the motor 3 is set at the bottom of the hopper 1, the output shaft of the motor 3 is provided with a sprocket 4.1, and the chain 4 is connected to the sprocket 4.1 for transmission , The eccentricity of the two cams 2 is the same, so that both...

Embodiment 2

[0012] Example 2: Reference figure 1 , A compound motion mechanism, including straight slot type hopper 1, cam 2, motor 3, and transmission assembly. The number of cams 2 is two, which are correspondingly arranged at the bottom ends of hopper 1. The transmission assembly includes chain 4 and several sprockets. 4.1. The drive shaft 5 connected with the sprocket 4.1. One end of the drive shaft 5 is connected with the sprocket 4.1, and the other end extends to the bottom of the hopper 1 to connect with a fixed cam 2. The bottom of the hopper 1 is provided with a cam seat 1.1 that matches with the cam 2. The cam seat 1.1 There is a cam cavity, the cam 2 is set in the cam cavity, the drive shaft 5 is supported and fixed by the fixing base 5.1, the motor 3 is set at the bottom of the hopper 1, the output shaft of the motor 3 is provided with a sprocket 4.1, and the chain 4 is connected to the sprocket 4.1 for transmission , The eccentricity of the two cams 2 is inconsistent, causing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com