Toggle rod clamping mechanism

A technology of clamping mechanism and toggle lever, which is applied in the direction of clamping, metal processing machinery parts, support, etc., can solve the problems of inflexible and convenient clamping or loosening, complex structure of clamping mechanism, general clamping effect, etc., and achieve clamping Convenient and fast holding, good clamping effect, flexible and stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

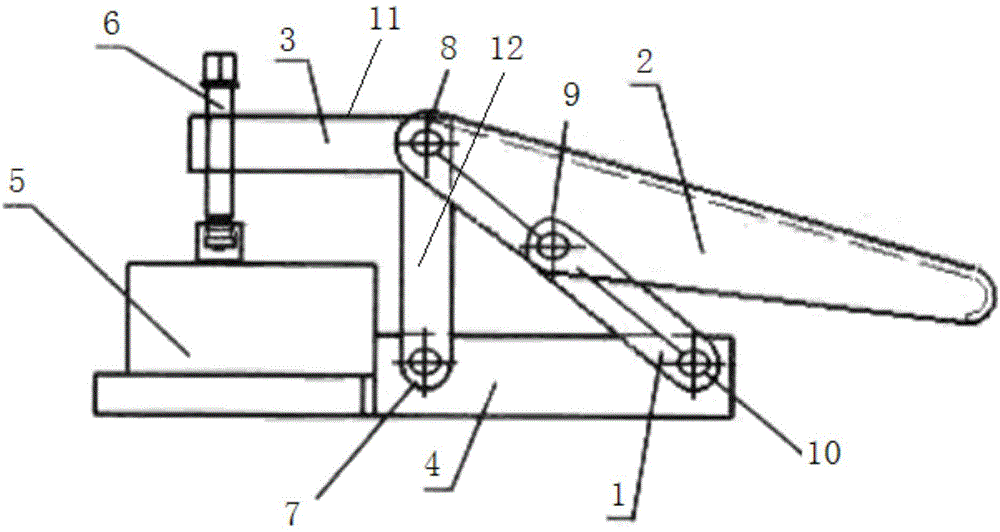

[0014] like figure 1 As shown, a toggle clamping mechanism includes a workbench 4, a first rocker 1, an L-shaped rocker 3, a connecting rod 2 and an adjusting screw 6, and the L-shaped rocker 3 includes a vertical plate 12 and a The horizontal plate 11 connected by the vertical plate 12, the bottom of the vertical plate 12 is hinged with the side of the middle part of the workbench 4 through the first pin 7, the horizontal plate 11 is provided with threaded holes, and the adjusting screw 6 can be connected with the threaded The holes are matched and connected, and the length of the adjusting screw 6 protruding from the threaded hole can be changed. The top end of the connecting rod 2 is hinged with the joint of the vertical plate 12 and the transverse plate 11 through the second pin shaft 8, and the first rocker 1 Arranged obliquely, the top end of the first rocker 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com