A system and method for safe tapping

A tapping system and safe technology, applied to heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve problems such as deviation error stepping distance, steel billets cannot be normally released from the furnace, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

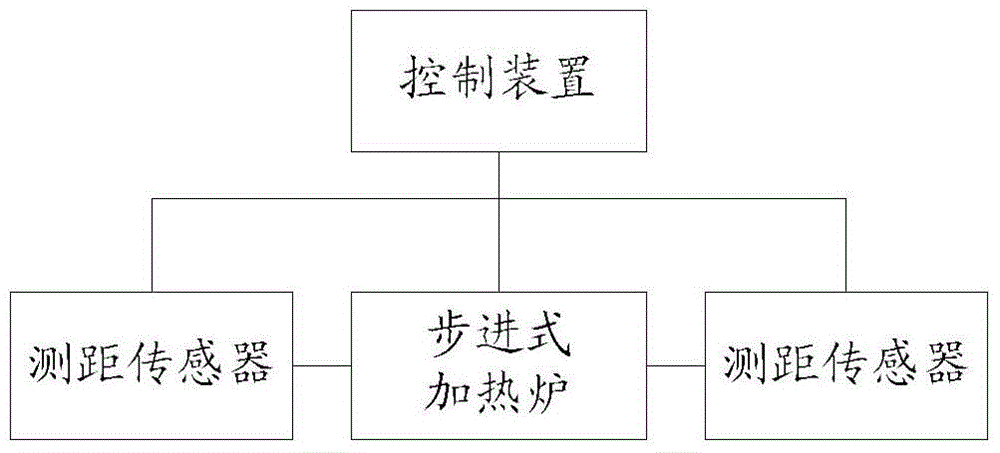

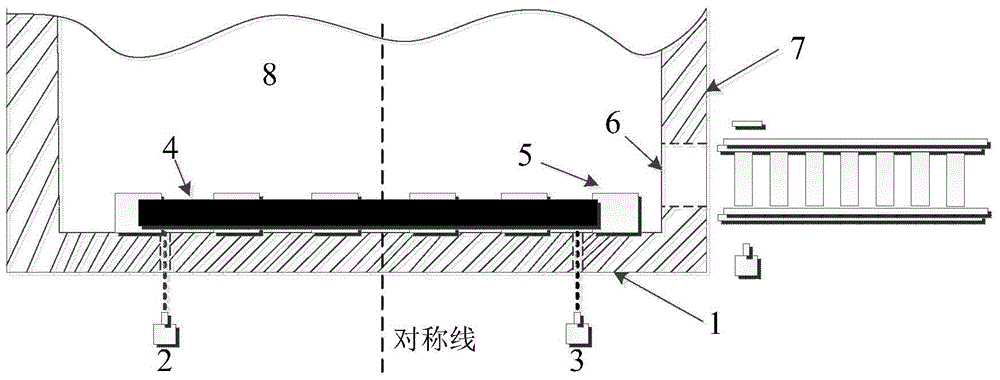

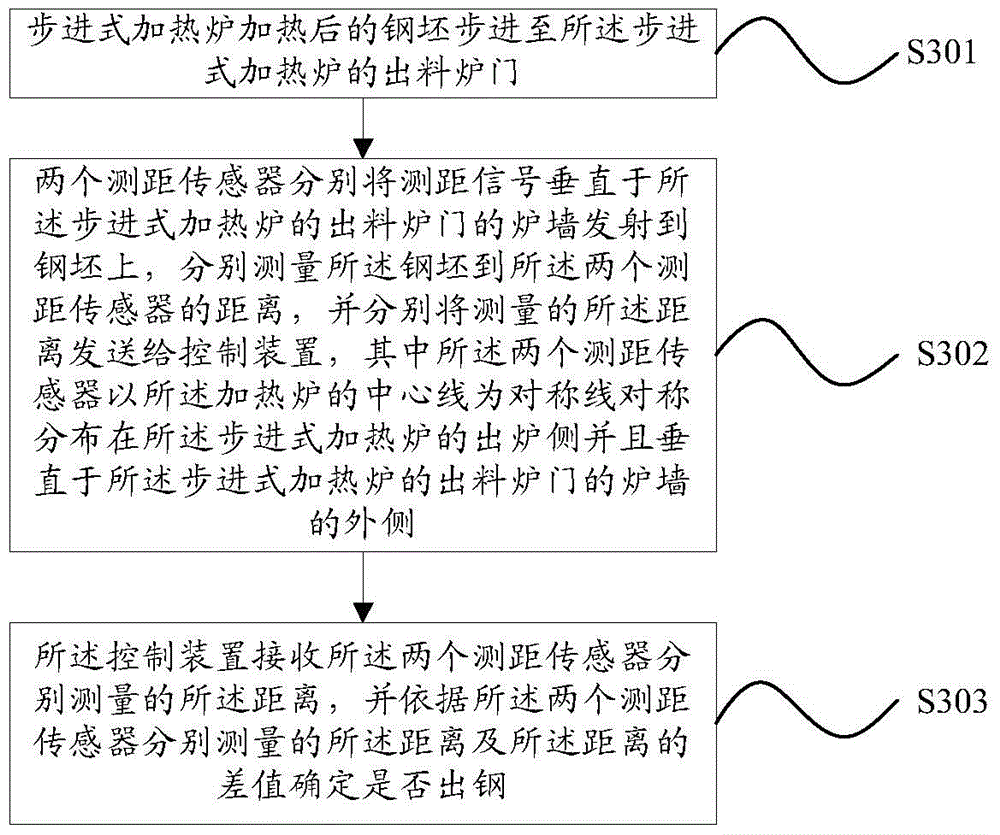

[0024] preferred, with figure 2 It is a system schematic diagram of embodiment 1 of a safe tapping system provided by the present invention, and the present invention provides a safe tapping system embodiment 2, combined with the attached figure 1 And attached figure 2 A safe tapping system is described in detail. figure 1 A safety tapping system shown includes a walking furnace, two distance measuring sensors and a control device. It should be noted that, for the convenience of description, the two range-finding sensors are recorded as the first range-finding sensor and the second range-finding sensor, specifically, as figure 2 The system shown is taken as an example. A safe tapping system includes a walking heating furnace 8, a first distance measuring sensor 2 and a second distance measuring sensor 3, and a control device. It should be noted here that the control device is in the figure 2 not shown in The walking heating furnace 8 is used to heat the billet 4 and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com