Three-gauge track changer

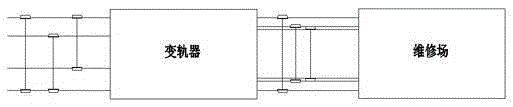

A three-gauge, wire-sleeve technology, applied in tracks, switches, movable tracks, etc., can solve problems such as inconvenient maintenance, and achieve the effect of improving use efficiency, saving construction funds and station land.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

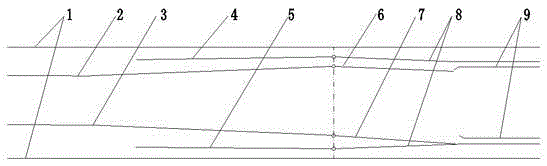

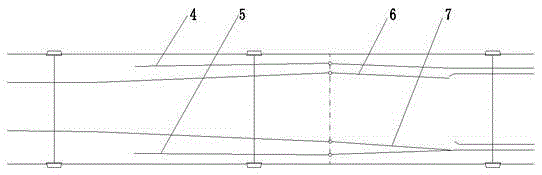

[0020] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0021] Such as figure 1 , figure 2 As shown, the three-gauge track changer of the present invention includes two 1435 standard rail basic rails 1, one 1065 narrow rail 2, one 1000 narrow rail 3, A point rail 4, B point rail 5, and C point Rail 6, D point rail 7, two connecting rails 8 and two guard rails 9. The front part of the track changer is used to connect the running line of the locomotive, and the rear part is used to connect to the locomotive maintenance yard. The two standard rail basic rails run through the rail changer. The 1065 narrow gauge, 1000 narrow gauge, A switch rail and B switch rail are placed inside the two basic rails of the standard rail at the front of the rail changer. The C point rail, D point rail, two connecting rails and two guard rails are placed inside the two standard rail basic rails at the rear of the rail changer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com