Pattern displacement sensor system for detecting position state of disconnecting link of transformer substation

A technology of grating displacement and knife gate position, which is applied to instruments, measuring devices, and optical devices, etc., can solve the problems of inability to realize remote inspection and inspection of substations, consuming a lot of manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

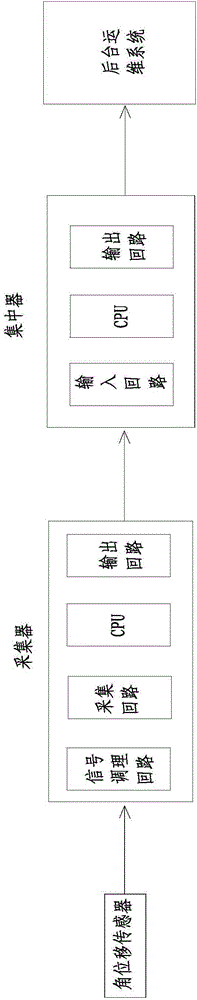

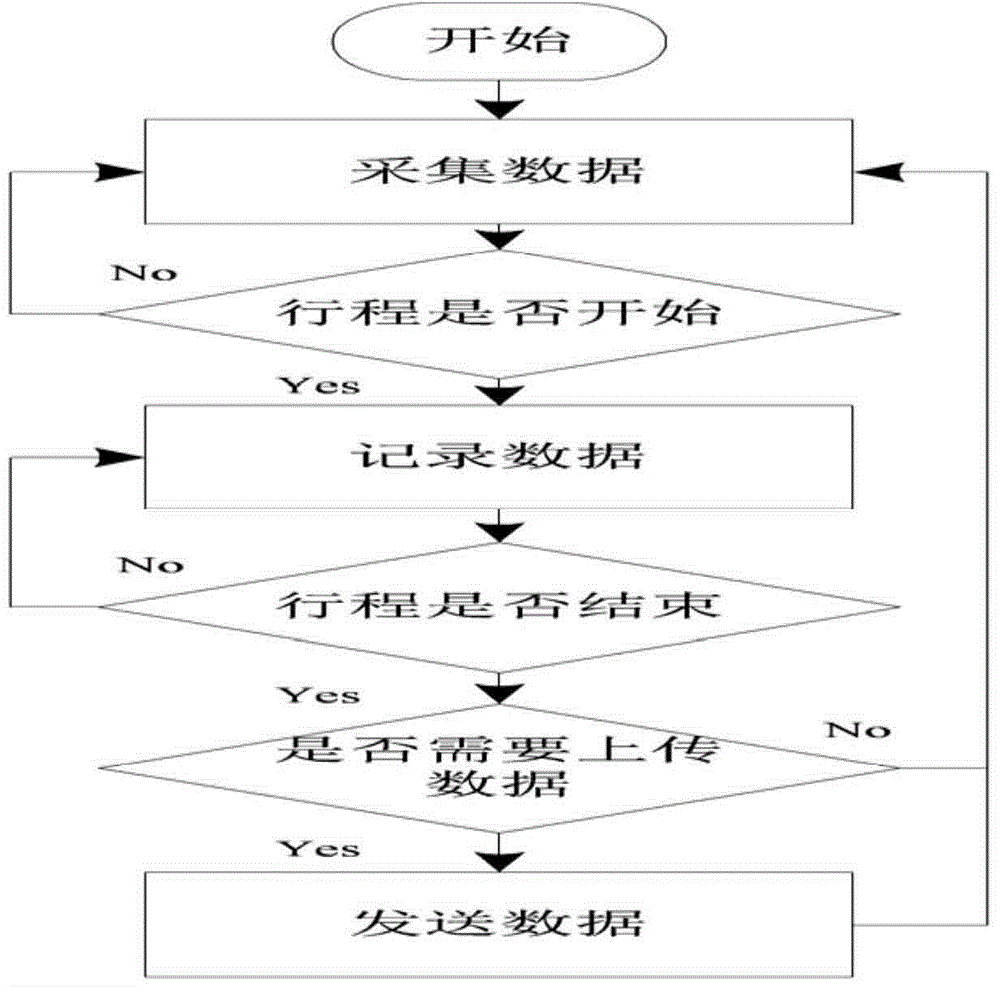

[0019] refer to Figure 1-2 , a grating displacement sensor system for detecting the position status of a switch in a substation, a grating displacement sensor and a background operation and maintenance system;

[0020] The grating displacement sensor collects the angular displacement change signal of the switch in the substation, and transmits it back to the background operation and maintenance system; the background operation and maintenance system compares the received angular displacement change signal with the preset maximum closing angle in the system Compare with the minimum closing angle; if the angular displacement change signal is greater than the minimum closing angle and smaller than the maximum closing angle, it is judged that the knife switch is closed. The maximum closing angle and the minimum closing angle are recorded by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com