Cable bending method

A bending and cable technology, applied in the field of cable bending radius controller and cable bending, can solve the problems of low professional quality of team members, insulation breakdown, hard extrusion of cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

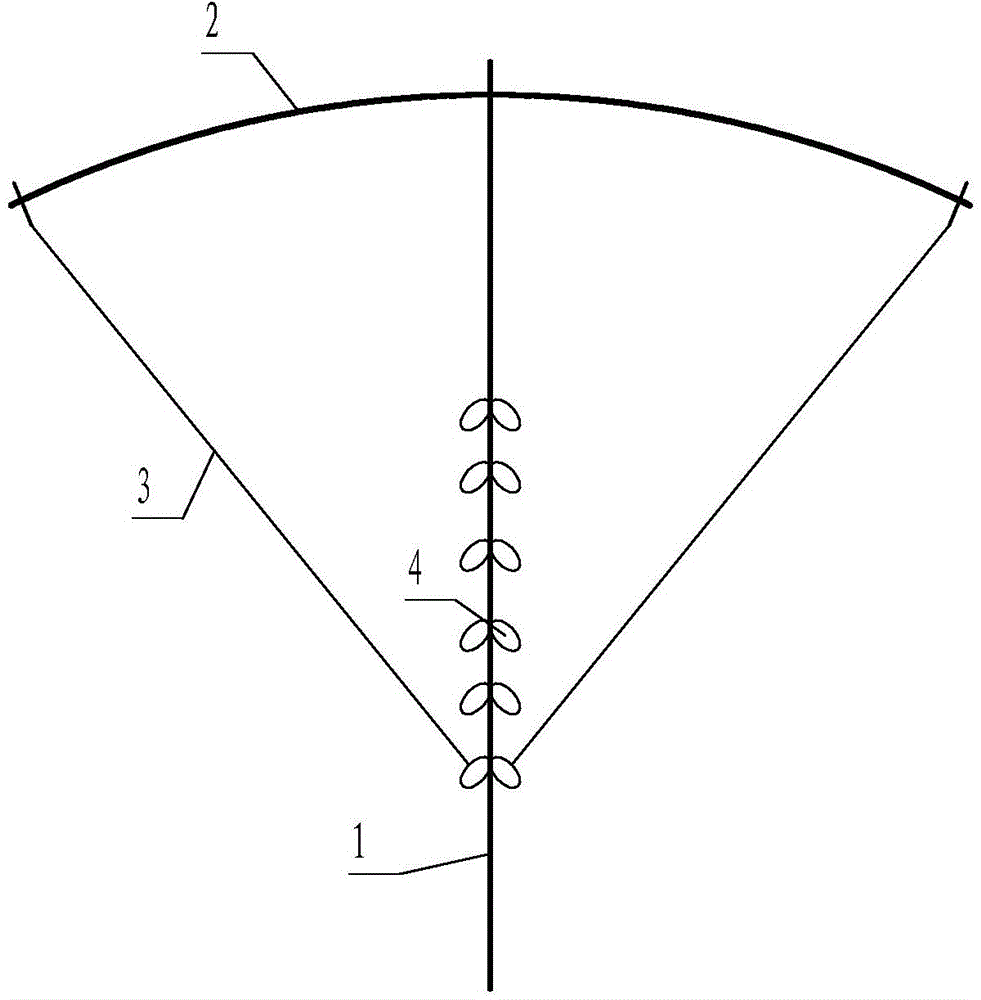

[0028] a kind of like figure 1 The shown cable bending radius controller includes a support rod 1, a bendable rod 2 and a pull cord 3, and a through hole for the bendable rod to pass is provided at one end of the support rod, and the axis of the through hole is vertical On the axis of the support rod, there are scale values distributed along the axis of the support rod on the support rod, and the two sides of the support rod at the scale 4 are provided with pull rings for hanging pull ropes, and at both ends of the bendable rod There are through holes for hanging and stretching. When working, one end of the two pull ropes is respectively connected to the through holes at both ends of the bendable rod, and the other end of the two pull ropes is respectively connected to the pull rings on the same scale value of the support rod. After being connected, the length of the stay cord between the bendable rod and the support rod is equal to the length between the corresponding scale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com