High-voltage capacitor component

A technology of high-voltage capacitors and capacitors, which is applied in the direction of capacitors and electrical components, can solve problems such as limited voltage, difficulties in mechanical and electrical connections, and inability to use, so as to improve the withstand voltage capability, improve the withstand voltage level and reliability, and achieve high-voltage The effect of electric field optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

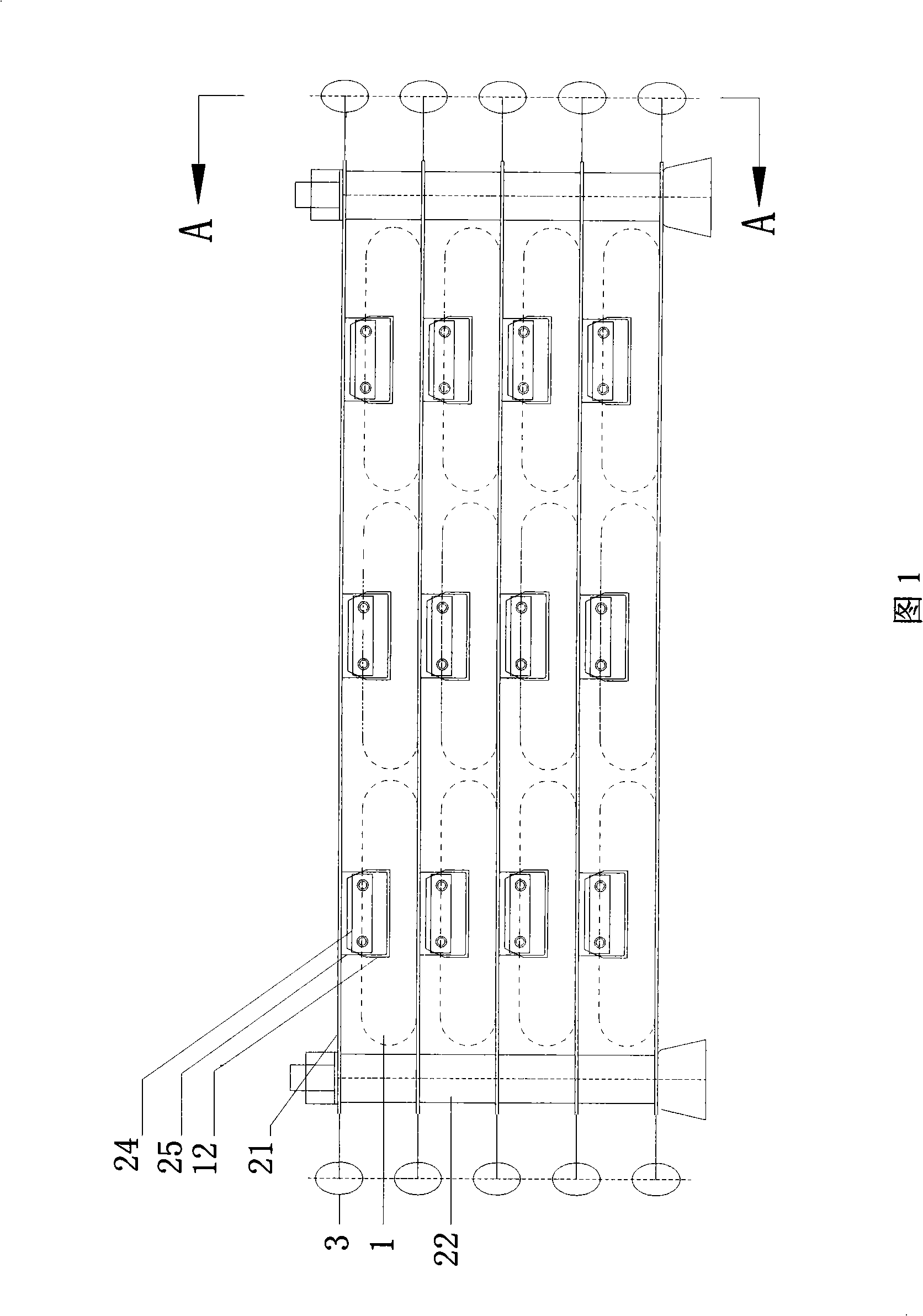

[0030] A high-voltage capacitor assembly as shown in FIG. 1 mainly includes two parts: a bare capacitor 1 and a capacitor assembly support 2 .

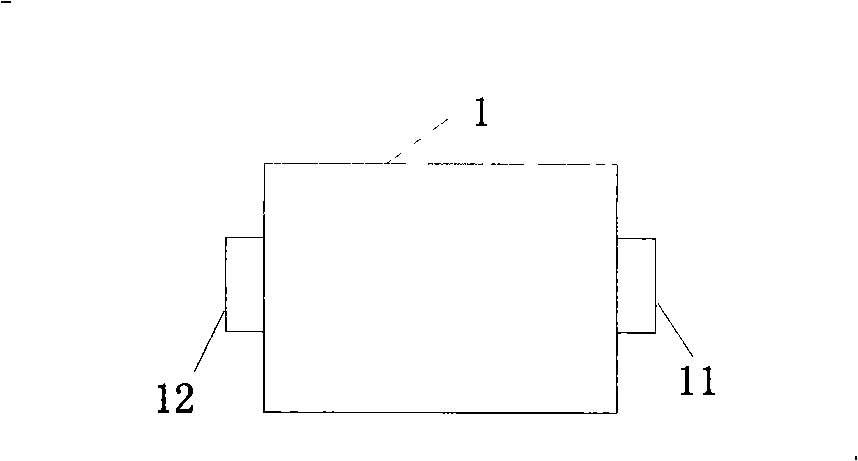

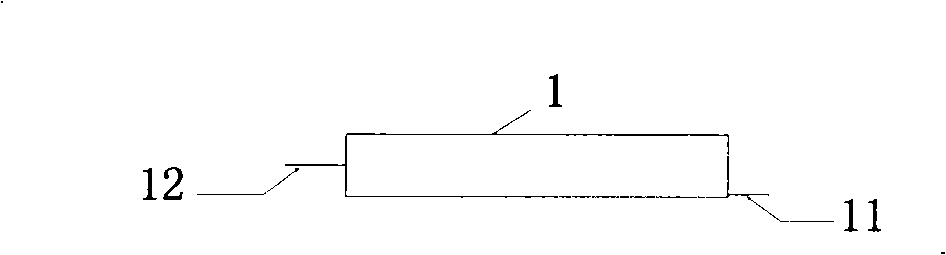

[0031] Among them such as figure 2 , 3 Shown is a schematic structural view of the bare capacitor 1 , which includes capacitor outer electrodes 11 and center electrodes 12 . Figure 1, Figure 4 , Figure 6 As shown, the capacitor assembly support 2 includes an aluminum plate 21 , an insulating support 22 , an electrode pressing piece 23 , an electrode pressing piece 24 , and an electrode metal support 25 . Several layers of aluminum plates 21 are insulated and supported by insulating pillars 22 arranged between every two layers of aluminum plates, and the height of insulating pillars 22 is determined according to the working voltage of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com