A tunnel air purification equipment

A technology for tunnel air and purification equipment, which is applied in the directions of external electrostatic separator, electrostatic separation, electrode cleaning, etc., can solve the problems of occupying tunnel space, difficult air purification, and squeezing the installation space of the purifier, so as to improve the processing air volume and improve the Effect of purifying air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

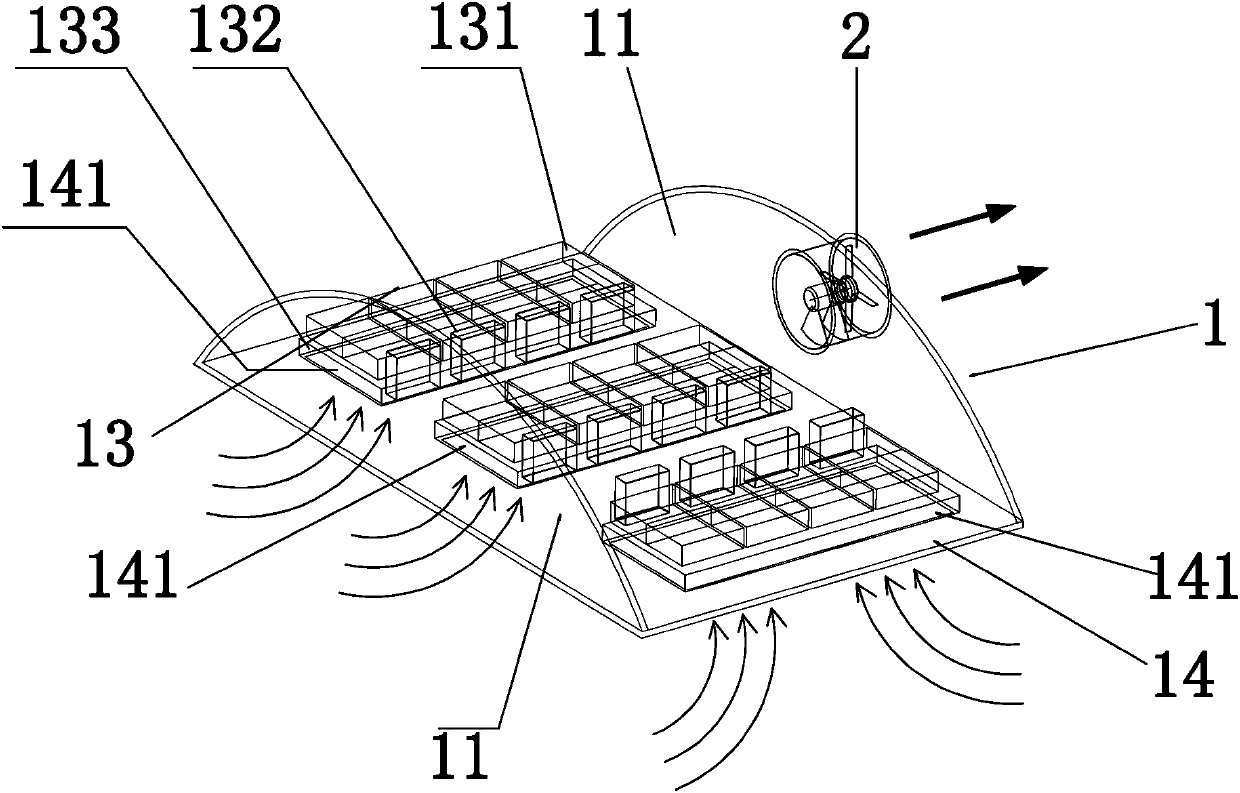

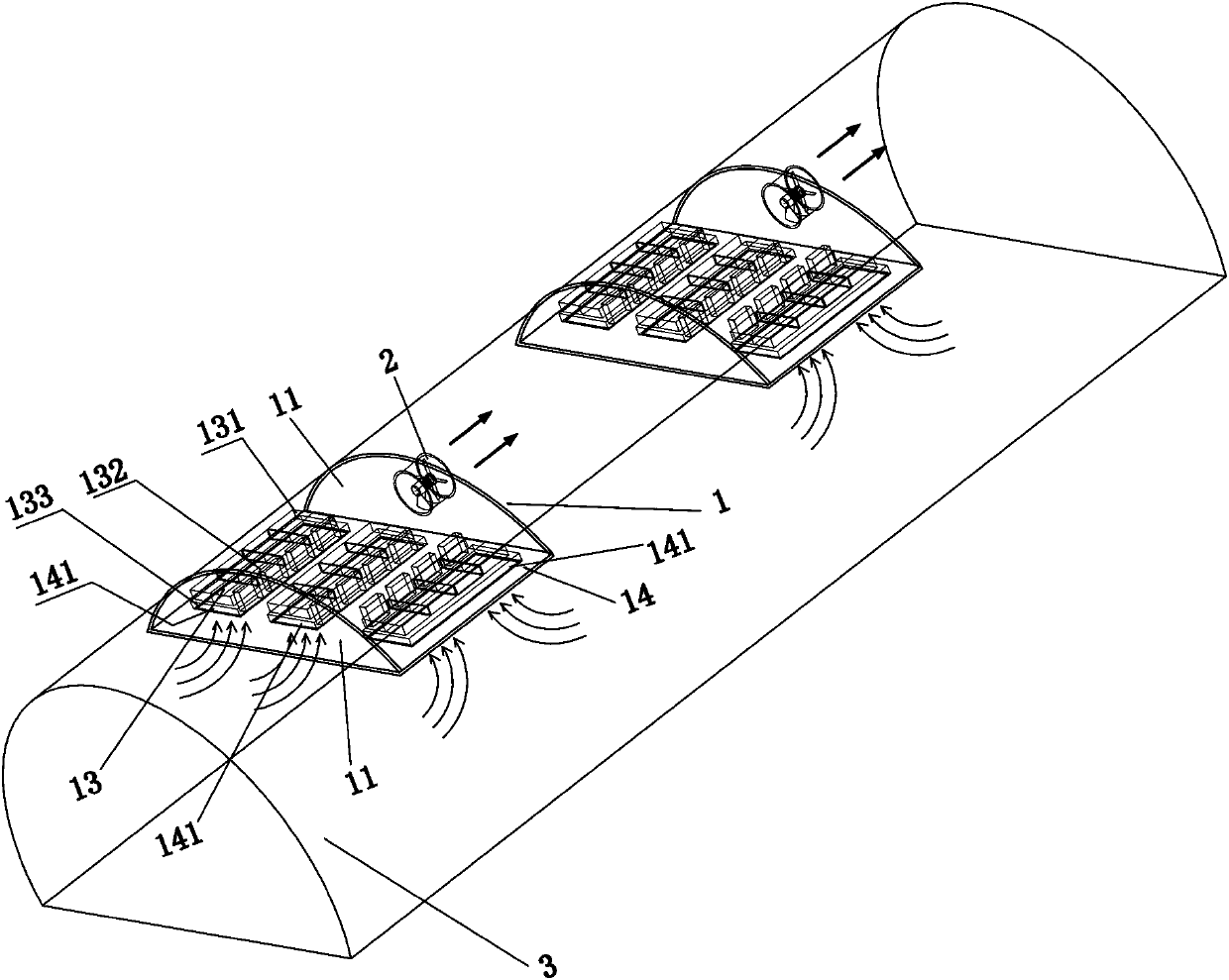

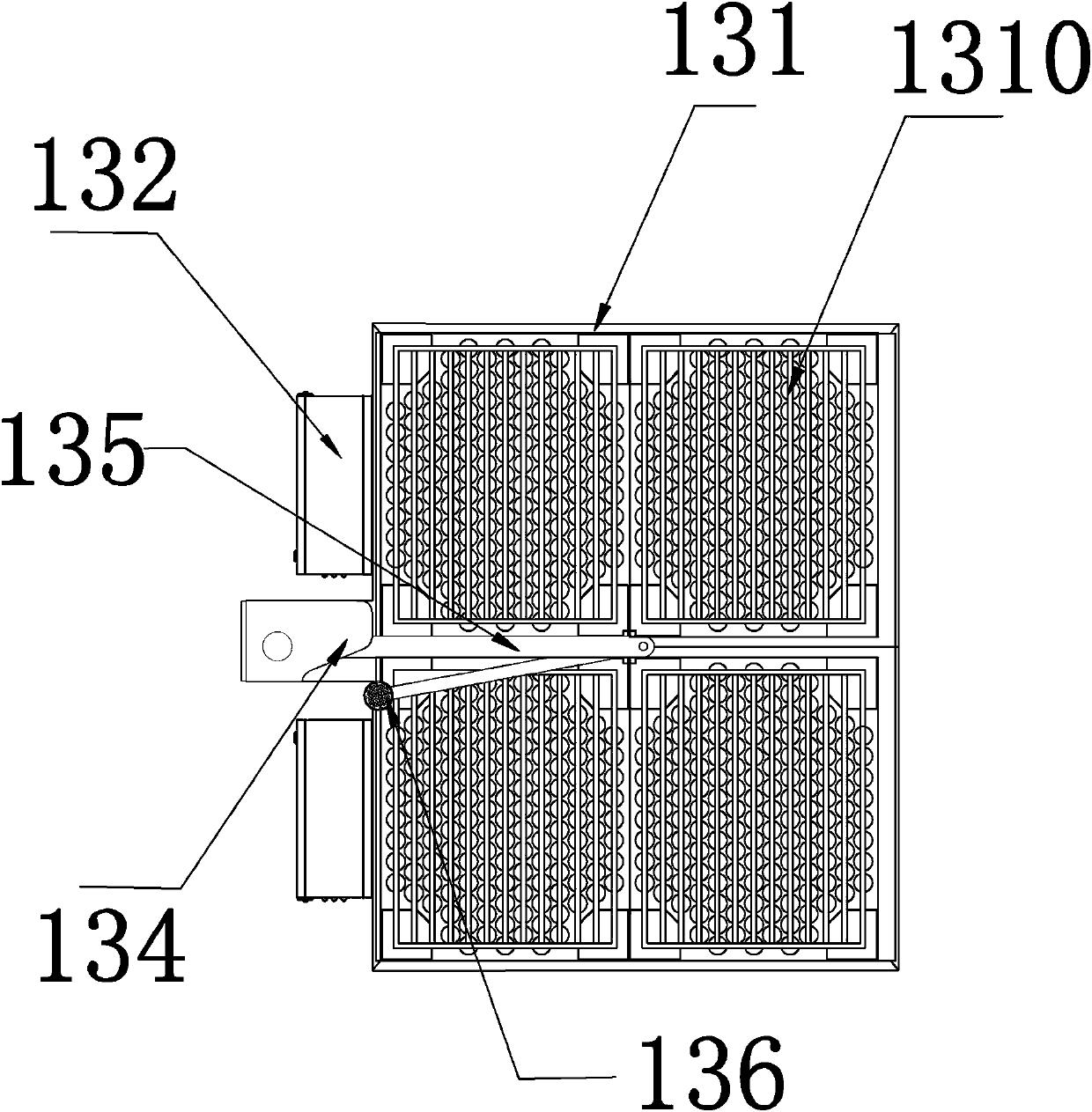

[0023] Such as figure 1 Shown, a kind of tunnel air cleaning equipment, comprises the clean room 1 that is used to purify air and the suction fan 2 that draws the air out of the clean room, and the suction fan 2 is arranged on one of the fan-shaped side panels 11 of the clean room 1; the clean room is A clean room 1 is formed by isolating the irregular (such as semi-cylindrical) space on the upper part of the tunnel; the clean room 1 includes two fan-shaped side panels 11 that fit and seal the top surface of the tunnel, a ceiling load-bearing surface 14, And several groups of cleaning units 13 for purifying air, wherein an exhaust fan 2 is installed on a fan-shaped side panel 11, and the other fan-shaped side panel 11 is in sealing conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com