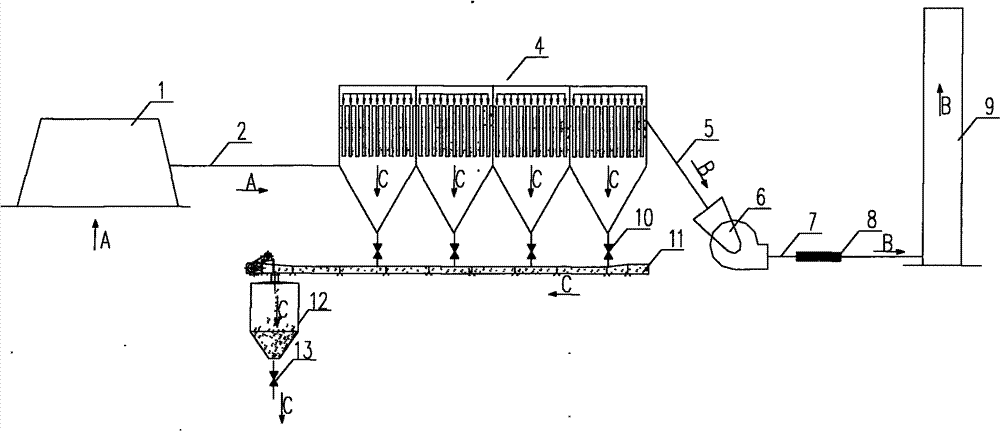

Ultrashort-flow technique for industrial dust removal

An ultra-short, process technology, applied in dispersed particle separation, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of large floor space, high resistance, high energy consumption, and achieve less maintenance workload, energy consumption and low energy consumption. Low noise and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

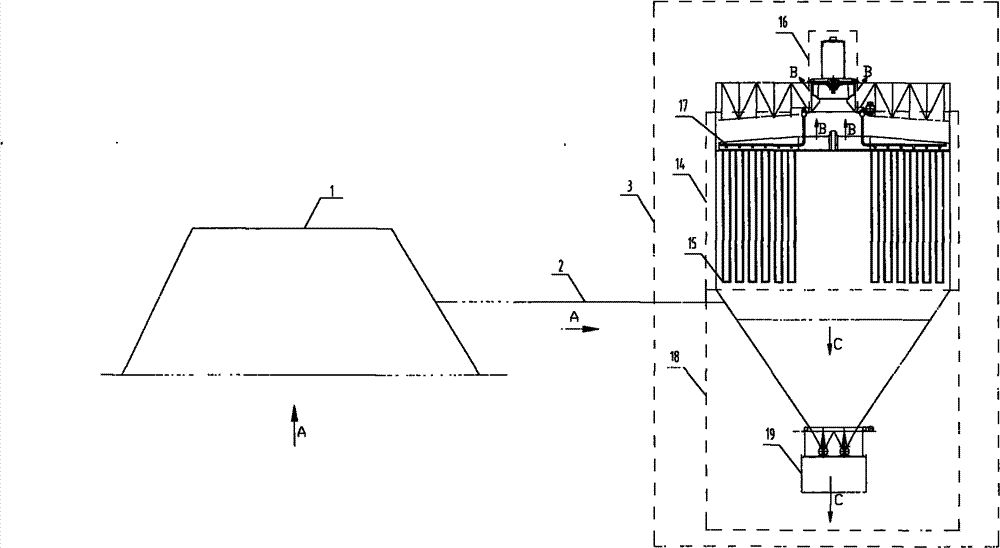

[0036] Below, combine figure 2 Specifically illustrate the implementation of the present invention:

[0037] The ultra-short industrial dust removal process is composed of a collection hood 1, a flue gas pipeline 2 and a large-scale integrated dust removal unit 3, which realizes the collection, purification, noise control of the existing industrial dust removal system flue gas, clean gas emission and dust-free dust Ash discharge and other functions. Under the negative pressure of the dust removal system, the industrial flue gas is collected by the collection hood 1, enters the integrated dust removal unit 3 through the pipe 2, and separates the gas and dust through the filter bag 15 in the flue gas purification unit 14, and the filtered clean gas Under the action of the negative pressure of the induced air exhaust unit 16, it is directly discharged into the atmosphere. The dust collected on the outside of the filter bag 15 falls into the ash storage and discharge unit 18 un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com