One-die forming small pad hooking die

A small loop, integrated technology, applied in sewing tools, textiles and papermaking, cloth feeding mechanism and other directions, can solve the problems of low processing efficiency, uneven processing allowance, unable to ensure the regular appearance of small loops, etc. Convenient and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

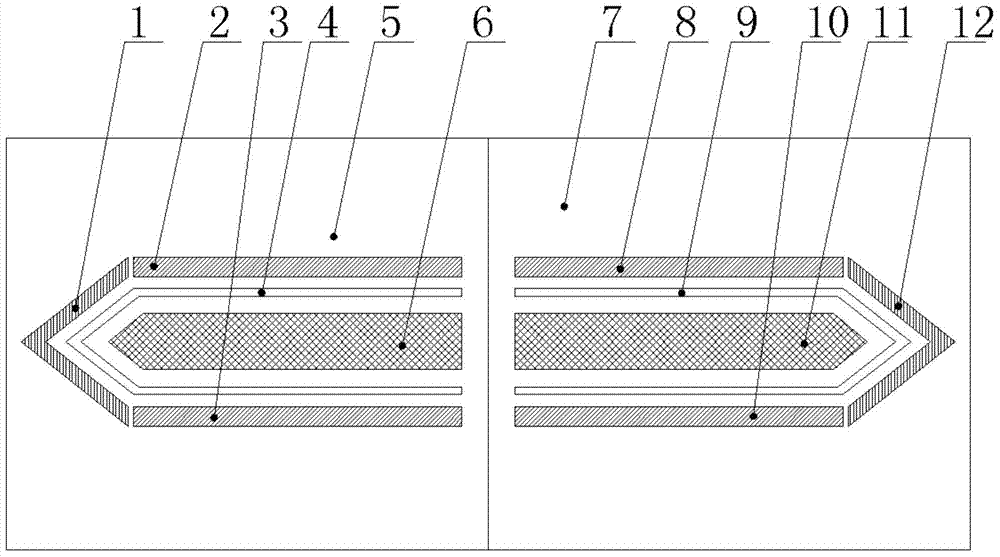

[0016] The integrally formed mold for the hook loop is composed of the left flap (5) and the right flap (7) with the same structure, and the middle part of the left and right flaps is axially symmetrically provided with a left hook line slot with the same shape as the loop (4), right hook line through groove (9).

[0017] Moreover, anti-slip strips A (2) and anti-slip strips B (3) are compounded on the upper and lower sides of the left hook line groove.

[0018] Moreover, anti-slip strips C (8) and anti-slip strips D (10) are compounded on the upper and lower sides of the right hook line groove.

[0019] More...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com