A method, device and system for automatically adjusting the angle of a probe emission line during puncture

A technology of firing angle and angle, which is applied in the fields of puncture needles, diagnostic probe accessories, medical science, etc., can solve the problems of manual adjustment, difficult to determine the deflection angle, manual adjustment of the firing line and puncture needle, etc., to enhance the accuracy, improve the Imaging efficiency and the effect of improving scanning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

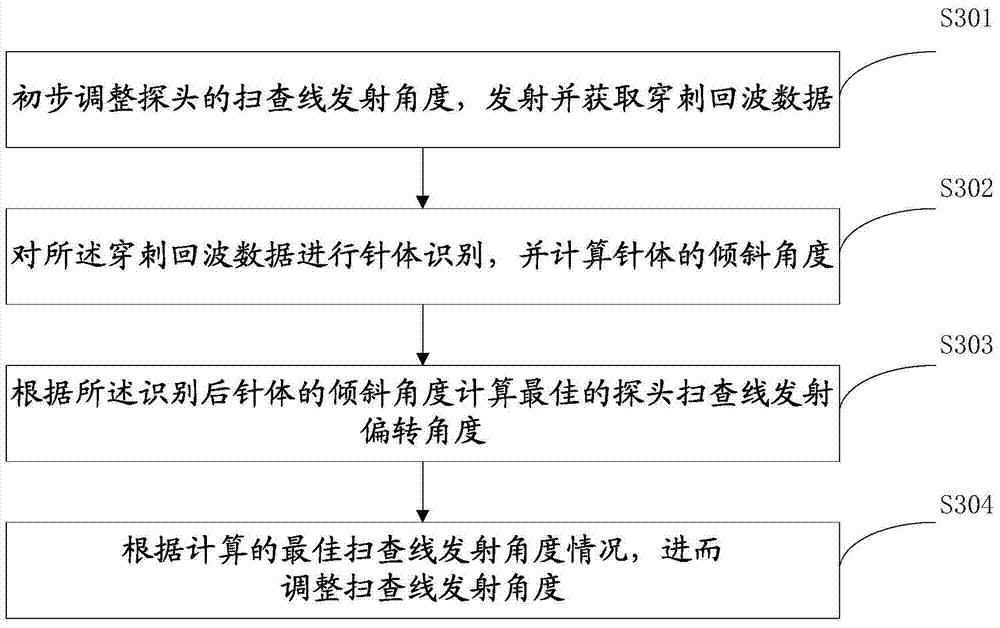

[0031] Such as figure 1 As shown, the method for automatically adjusting the angle of the probe emission line in the puncture includes the following steps:

[0032] S101, preliminarily adjusting the scanning line emission angle of the probe, emitting and acquiring puncture echo data.

[0033] By manually adjusting the deflection angle of the scanning line of the probe, the preliminary puncture echo data can be obtained. Theoretically, when the scanning line emission angle of the probe is at an optimized angle perpendicular to or close to the perpendicular (between 85-95 degrees) to the puncture needle, the display of the puncture needle is most obvious.

[0034] When using a linear array probe for scanning, usually the puncture needle and the linear array probe are not used in conjunction with the puncture frame, and manual adjustment is required. Usually, it is difficult to accurately obtain the required optimal angle through manual adjustment. Therefore, the display of the...

Embodiment 2

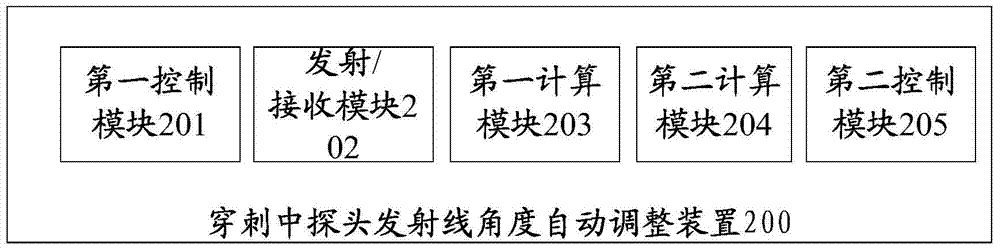

[0076] Such as image 3 As shown, the present invention also provides a puncture needle display device, which includes: a first control module 201 , a transmitting / receiving module 202 , a first calculation module 203 , a second calculation module 204 , and a second control module 205 .

[0077] The first control module 201 is used to preliminarily adjust the scanning line emission angle of the probe;

[0078] A transmitting / receiving module 202, configured to transmit and acquire puncture echo data;

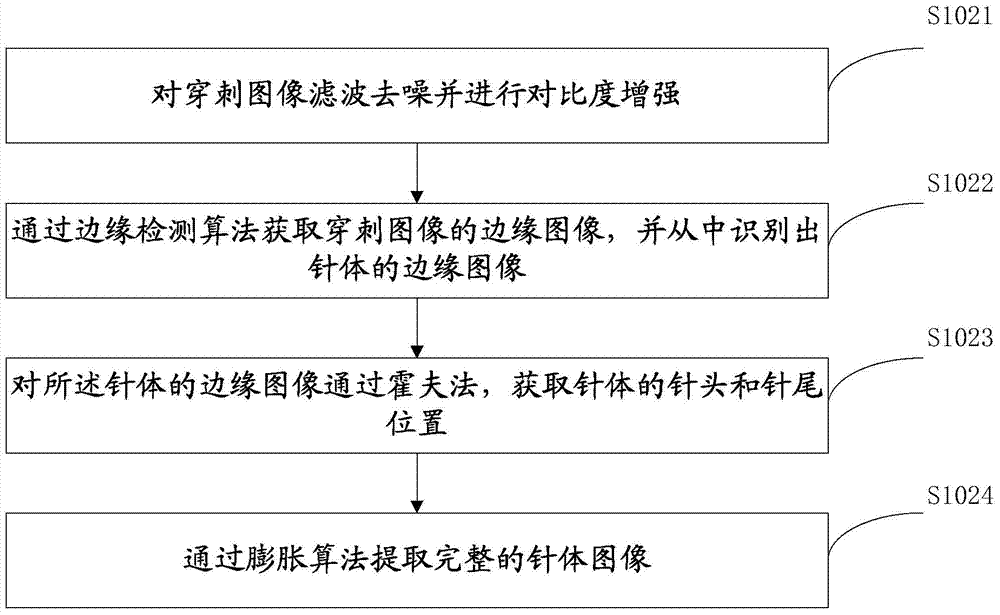

[0079] The first computing module 203 is configured to perform needle body recognition on the puncture image echo data, and calculate the inclination angle of the needle body; specifically, it includes the following:

[0080] Used to filter and denoise the puncture image and perform contrast enhancement;

[0081] It is used to obtain the edge image of the puncture image through the edge detection algorithm, and identify the edge image of the needle body therefrom;

[0082] It...

Embodiment 3

[0090] The present invention also provides a system, the system has the device as described in the second embodiment, the device and the working process of the device are detailed in the first and second embodiments and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com