A sand ball flexible rice mill and a grain medium rice milling method

A technology of rice milling machine and sand ball, which is applied in the direction of grain processing, application, grain pod removal, etc. It can solve the problems of reducing the speed of the milling roller, reducing the pressure of the rice milling room, and the pressure of the rice milling room. The grinding area is beneficial to the effect of grinding and shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

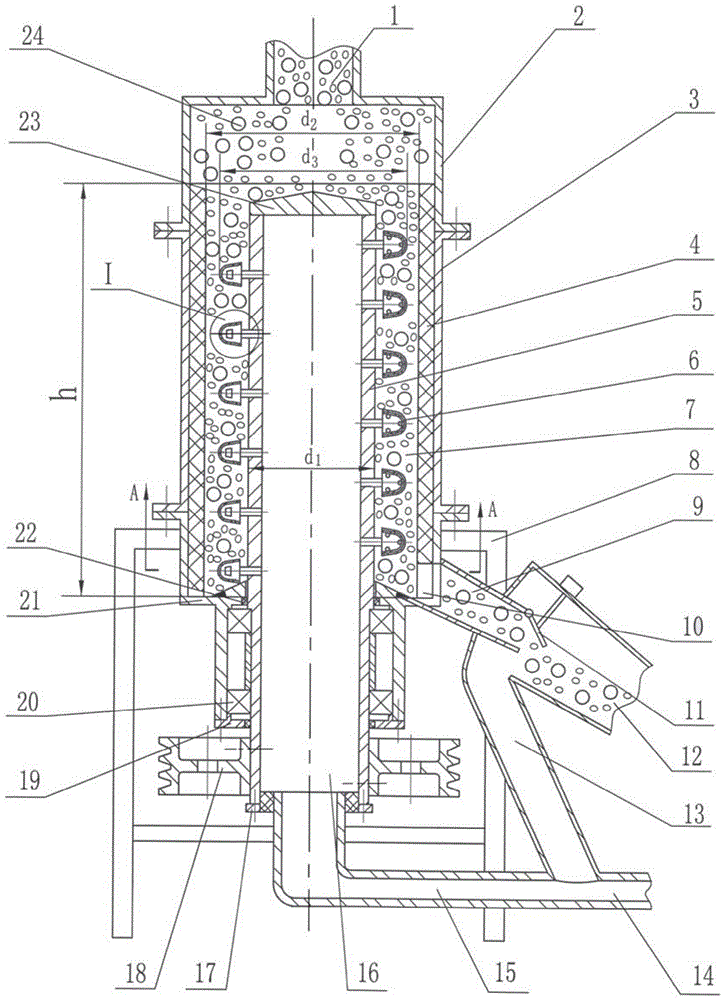

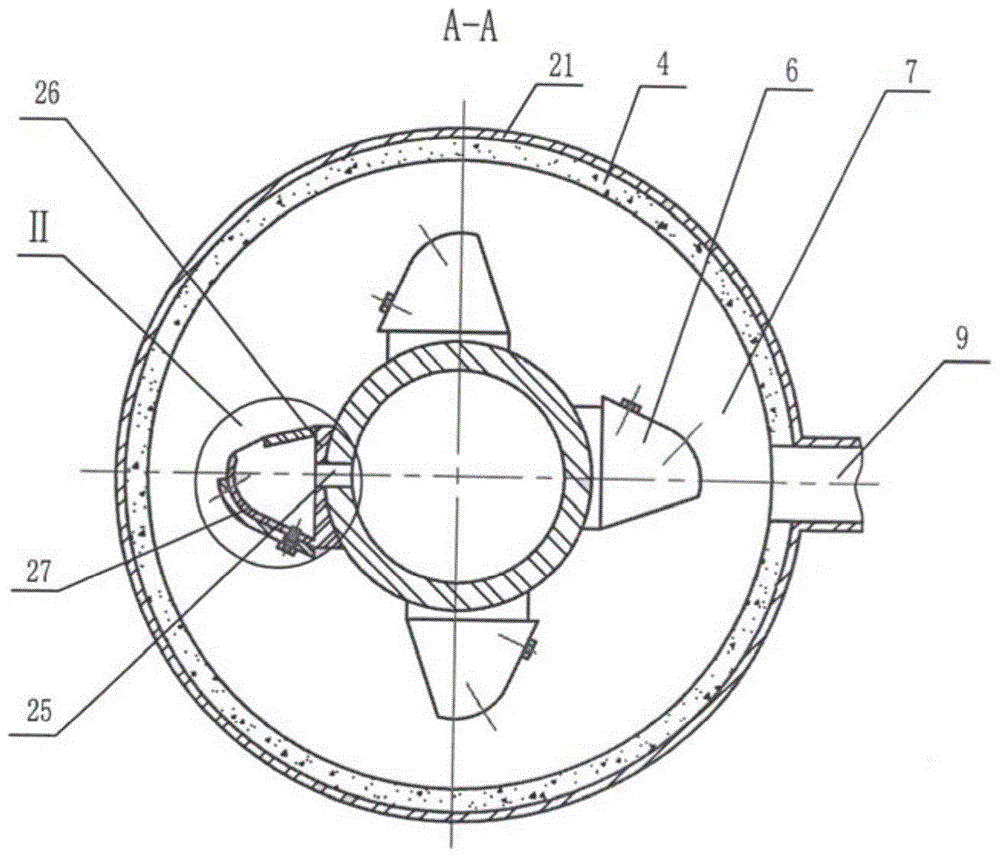

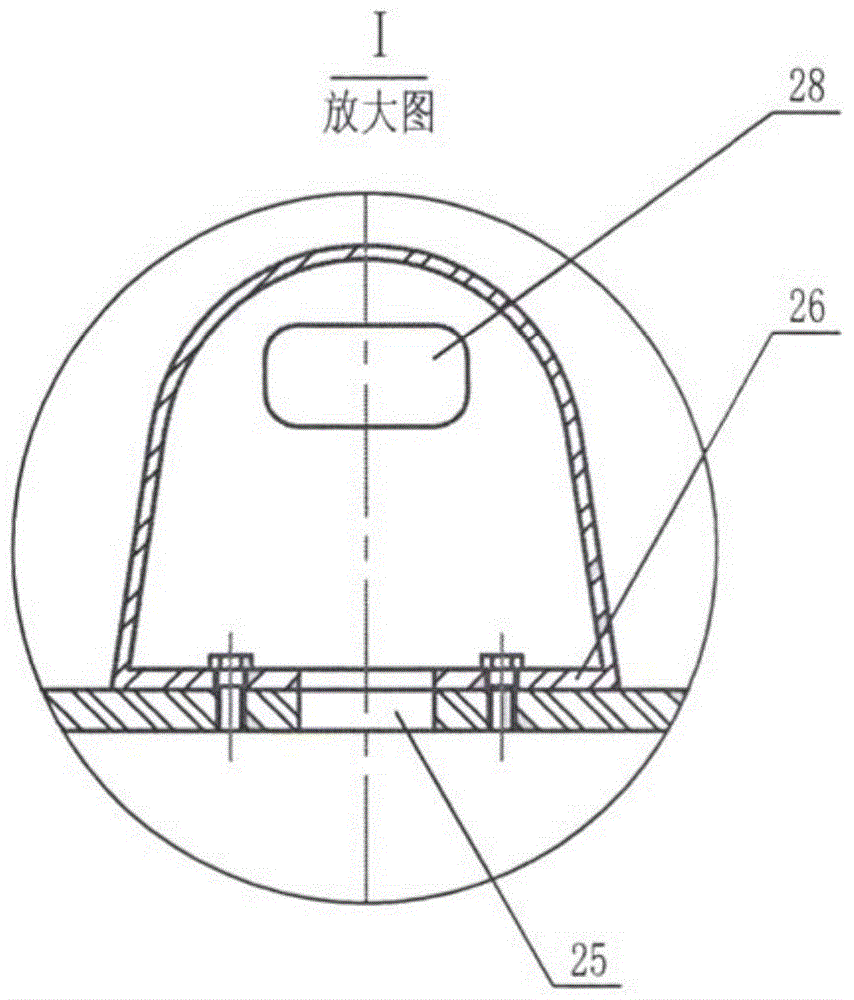

[0056] sand ball flexible rice mill figure 1 , figure 2 , image 3 , Figure 4 As shown, it is mainly composed of a machine barrel base, a machine outer cylinder, a machine cover, an emery inner cylinder, a hollow shaft, a paddle, a bearing assembly, a pulley, etc.; The upper end is connected to the machine cover 2, and the emery inner cylinder 4 is installed on the top of the machine barrel base and the inner side of the outer cylinder of the machine, and the bearing assembly 20, the upper end sealing assembly 22, the lower end sealing assembly 17, and the bearing cover 19 are used in the center of the machine barrel seat to install the hollow shaft 5;

[0057] The hollow shaft is a hollow cylinder. The top of the hollow shaft 5 is equipped with a material rejection tray 23. A plurality of paddles 6 are installed symmetrically and uniformly on the outer surface of the hollow shaft. The 5 lower ends utilize the lower end sealing combination 17 to connect the chaff suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com