A kind of packaging machinery lane change switching device

A switching device and packaging machinery technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the time-consuming and labor-intensive problems, and achieve the effect of convenient lane change, reasonable design, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

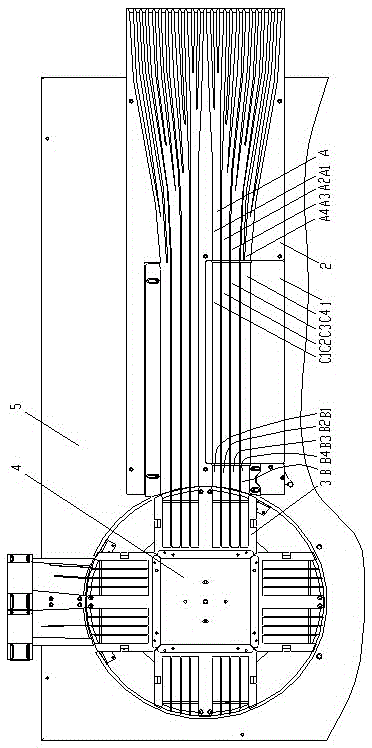

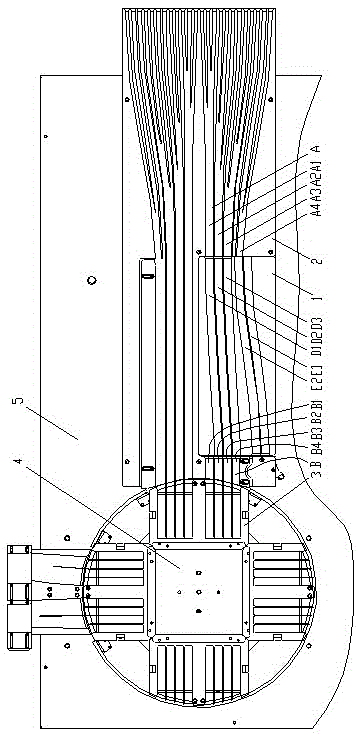

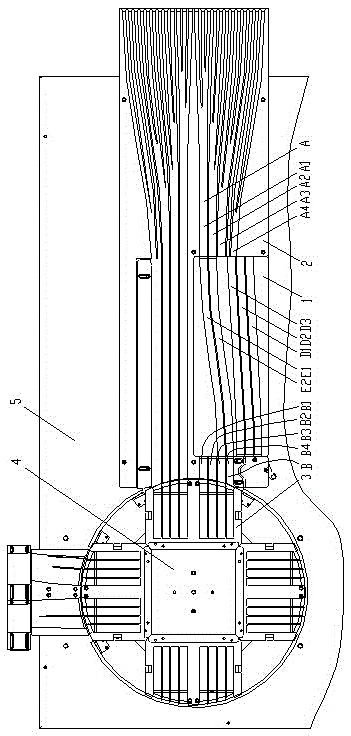

[0025] Such as figure 1 , figure 2 or image 3 As shown, the lane-changing switching device for packaging machinery of the present invention includes a bottom plate 5 , a front channel plate 2 , a rear channel plate 3 and a switching plate 1 . The front passage plate 2 is provided with a front passage A, and the front passage A includes an inner reference passage and an ordinary passage. In this embodiment, the front passage A includes four U-shaped (section) material passages: front passage IA1, The front channel ⅡA2, the front channel ⅢA3 and the front channel IVA4, that is, the number of material channels in the front channel A is 4, and the specifications (width and height) of the four material channels in the front channel A are the same, and the distance between the channels (the distance between the center lines) Similarly, the innermost channel of the front channel A, in this embodiment, the front channel IA1, is set as the inner reference channel; the rear channel ...

Embodiment 2

[0043] This embodiment is basically similar to Embodiment 1, the difference is that in this embodiment, the number of material passages in the front passage A is 2-10, and the number of material passages in the rear passage B is 2-10, that is, the front passage A and the rear channel, each including at least 3 material channels, each including a maximum of 10 material channels; the number of material channels for the switching channel is 1-10, that is, the switching channels include at least 1 material channel, and each includes 10 at most. Material channel. When the number of material channels of the switching channel is 1, the channel is used as both the inner channel and the outer channel, and the entrance and exit of the channel are respectively aligned with the inner reference channel and the outer reference channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com