Folded expansion bolt

A technology of expansion bolts and bolts, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems of low bearing capacity, easy loosening of stone plates, and troublesome disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

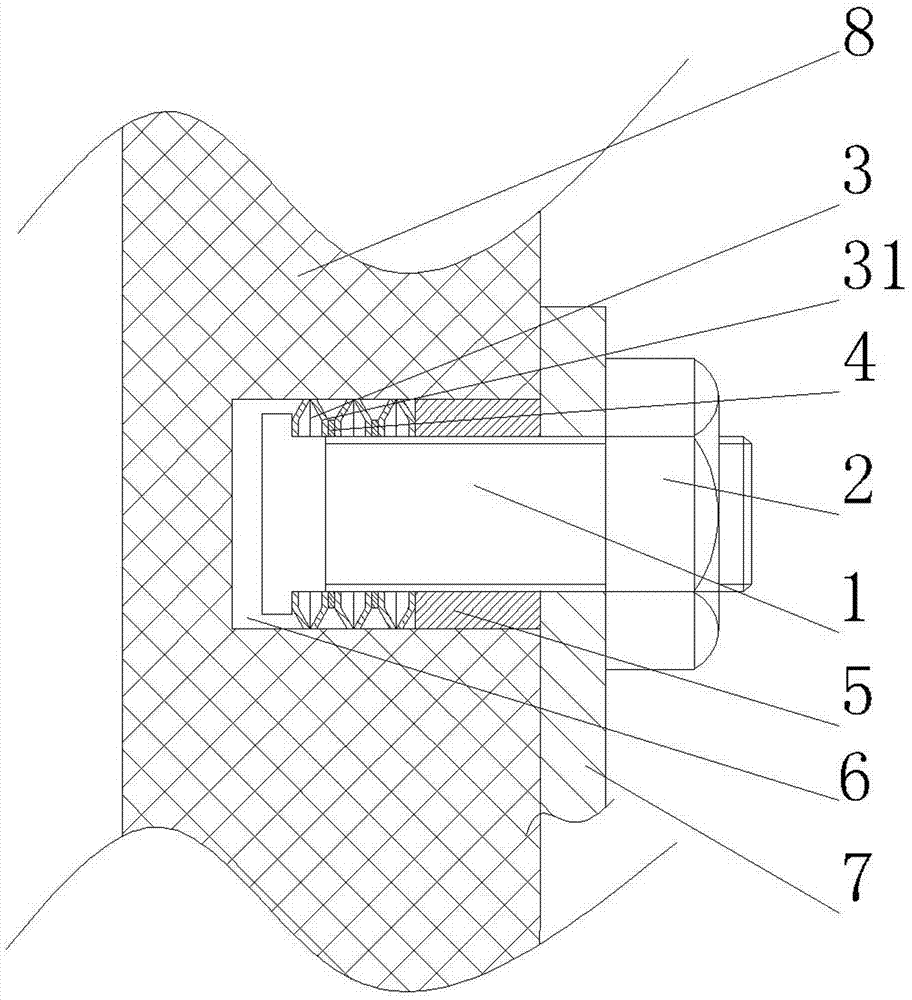

[0013] Such as figure 1 , figure 2 , image 3 As shown, a stacked expansion bolt includes a T-shaped bolt 1, a nut 2 set on the T-shaped bolt 1, several pairs of stacked frustum-cone expansion sleeves 3 set on the T-shaped bolt 2, Sleeve 4 on the outside of stacked frustum expansion sleeve 3 . When in use, press the overlapping expansion bolts into the mounting holes, the outer end of the T-bolt 1 passes through the pendant 7, and then screw on the nut 2, the T-bolt 1 goes outward, and the overlapping expansion bolts are connected between the T-bolt 1 and the sleeve. Expand under the action of the cylinder 4 to make it fill the entire hole, fix the pendant 7 on the wall 8, and then fix the stone plate 4 on the pendant 7.

Embodiment 2

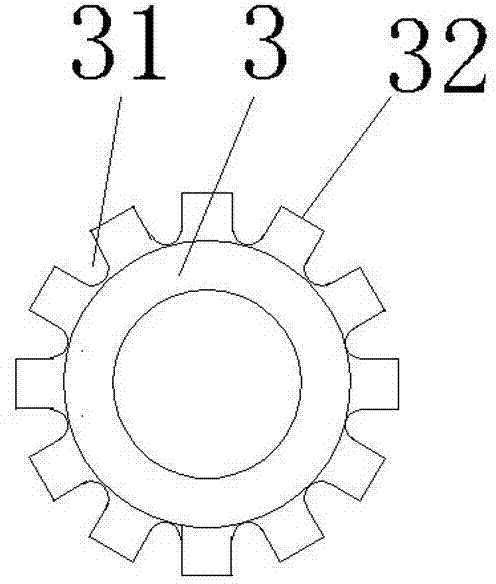

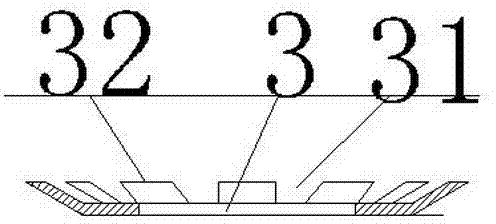

[0015] Such as figure 1 , figure 2 , image 3 As shown, the overlapping frustum expansion sleeve 3 is formed by overlapping the lower bottoms of two frustum expansion sleeves 31. A spacer ring 5 is provided between the overlapping expansion sleeves 3 to prevent adjacent The frustum expansion sleeves 31 fit together to reduce the bending force when the frustum expansion sleeves 31 are installed, and facilitate the entry of the frustum expansion sleeves 31 into the installation hole 6. The outer surface of the sleeve 4 and the lower bottom of the frustum expansion sleeve 31 The diameters are equal, and the sleeve 4 is used to press the stacked frustum-cone expansion sleeve 3 into the installation hole 6 during installation. The upper bottom of the frustum-cone expansion sleeve 31 is equal to the outer diameter of the spacer ring 5 . The lower bottom of the frustoconical expansion sleeve 31 is provided with several notches 32 to form several openings 33 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com