A kind of leather ball and its manufacturing process

A technology for pasting leather balls and skins, which is applied in the field of pasting balls and its production process, which can solve the problems of skin degumming and peeling, loose structure, and unsightly appearance, and achieve the effect of overcoming gaps and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, invention is further described:

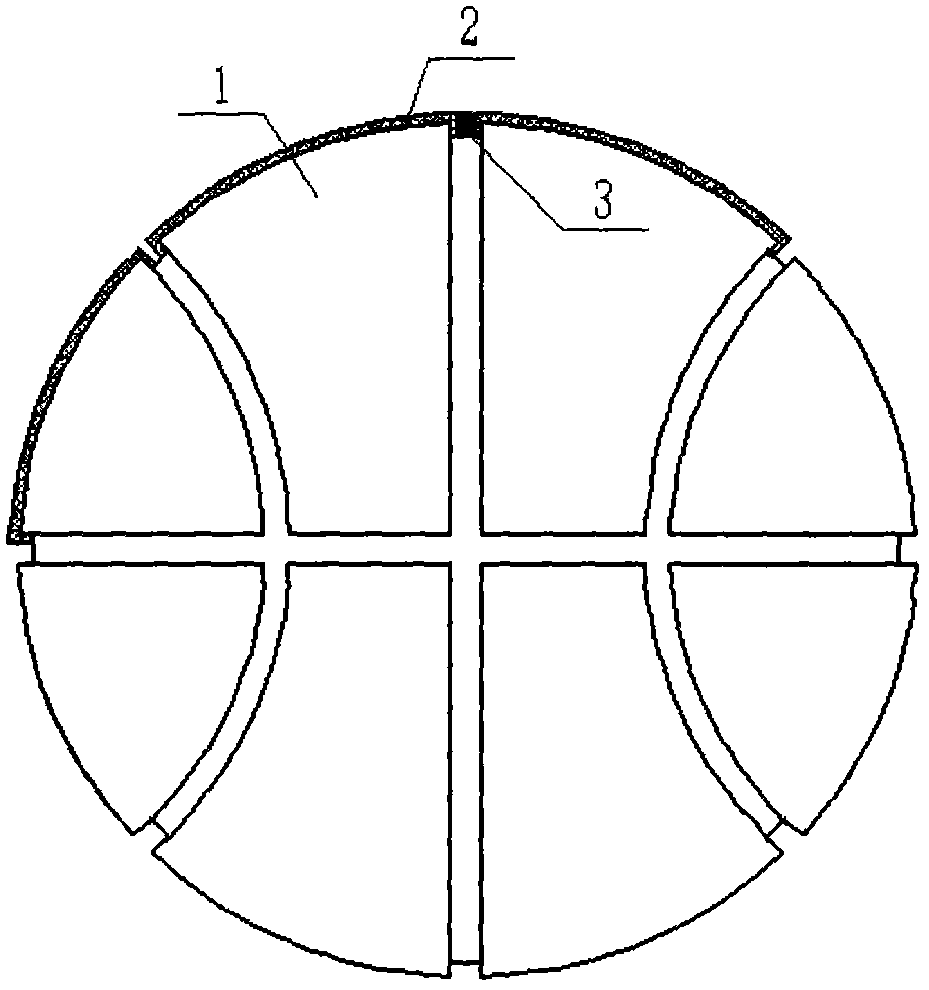

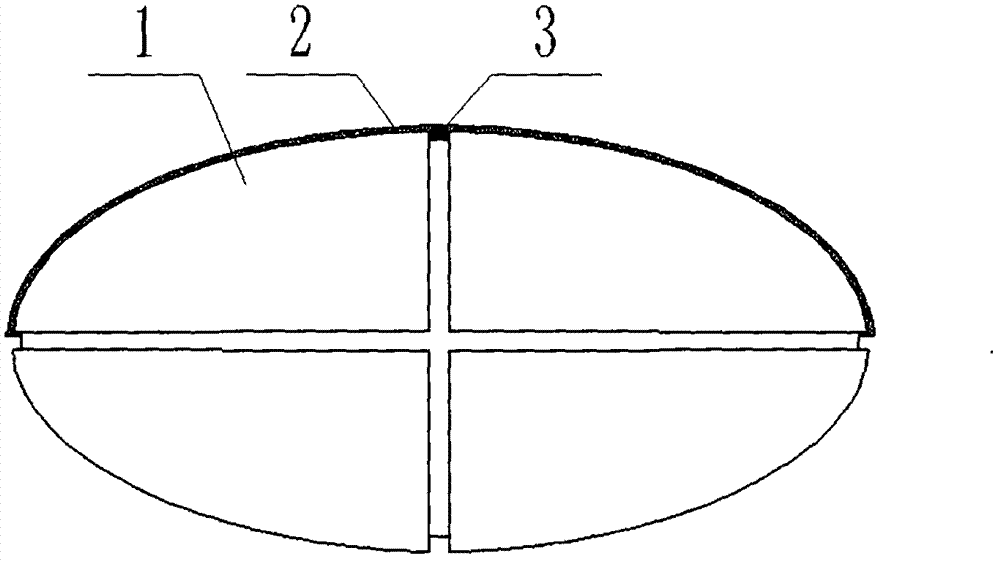

[0027] Such as figure 1 Shown is the structural representation of the first preferred embodiment of the present invention, and a kind of pasted ball that the present invention provides in the figure is basketball, comprises vulcanized middle tire 1, outer skin 2, stem bar 3, and the outer surface of described vulcanized middle tire 1 is provided with A plurality of grooves, the grooves divide the outer surface of the vulcanized middle tire 1 into several areas according to the ball specification, and the outer skins are respectively pasted on the vulcanized middle tires by glue, and the width of the outer skins is slightly larger than that of the vulcanized middle tire. The width of the tire 1 area, the part of the outer skin 2 that is wider than the vulcanized tire 1 area is attached to the side edge of the groove by flanging, and the stem bar 3 is pressed in the groove by glue; The widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com