Novel mechanical carrier for warehouse based on weighing device

A weighing device and truck technology, applied in the field of mechanical processing, can solve the problems of goods weight display, inability to carry out weighing, low work efficiency, etc., and achieve the effects of improving work efficiency, avoiding damage and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

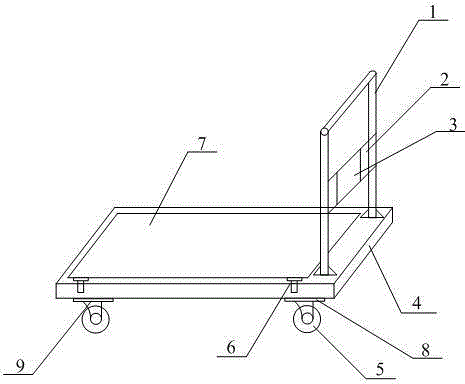

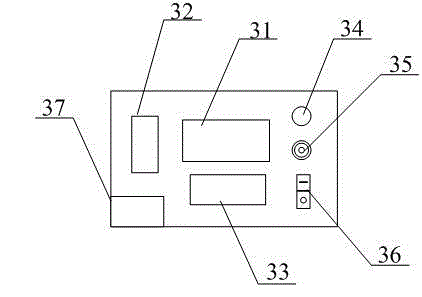

[0020] as attached figure 1 And attached figure 2 shown

[0021] The invention provides a new type of warehouse mechanical transport vehicle based on a weighing device, which includes a handrail 1, a mounting plate 2, a weighing device 3, a bottom plate 4, rollers 5, a sensor 6, a weighing plate 7, a universal bracket 8 and a fixed Bracket 9, the armrest 1 is arranged on the upper part of the right side of the base plate 4; the installation plate 2 is arranged and fixed in the middle of the handrail 1; the weighing device 3 is arranged and installed in the middle of the installation plate 2; The rollers 5 are installed on the bottom of the universal bracket 8 or the fixed bracket 9 respectively; the sensors 6 are respectively installed and fixed on the four corners of the bottom of the weighing plate 7; the universal bracket 8 is installed on the right side of the bottom of the base plate 4; The above-mentioned fixed bracket 9 is arranged on the left side of the bottom plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com