Air column type automatic positioning wool trimming device

An automatic positioning and trimming device technology, applied in the field of wool trimming, can solve the problems of increasing the difficulty of trimming, increasing the workload of users, and affecting the quality of wool finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

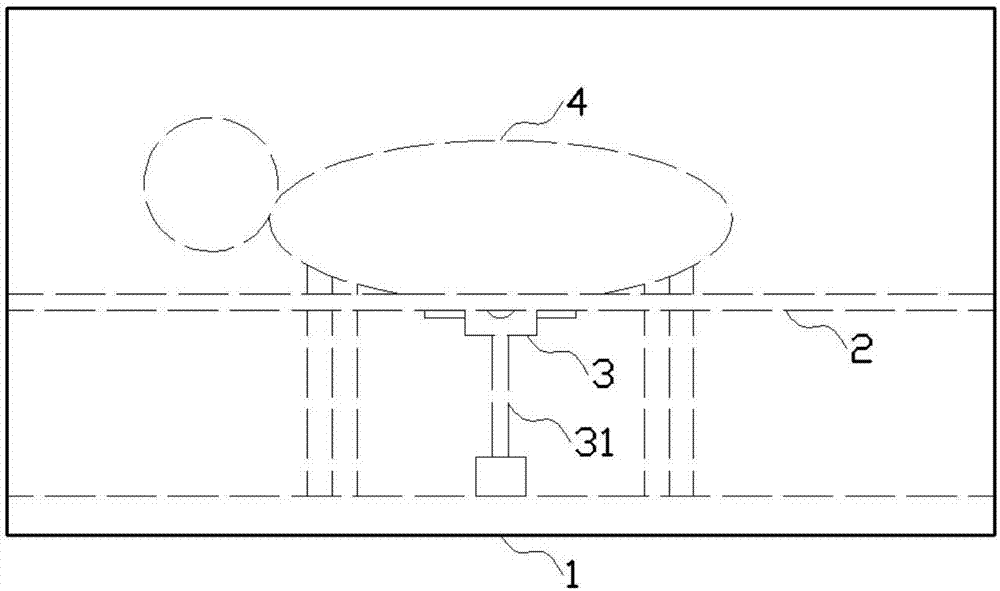

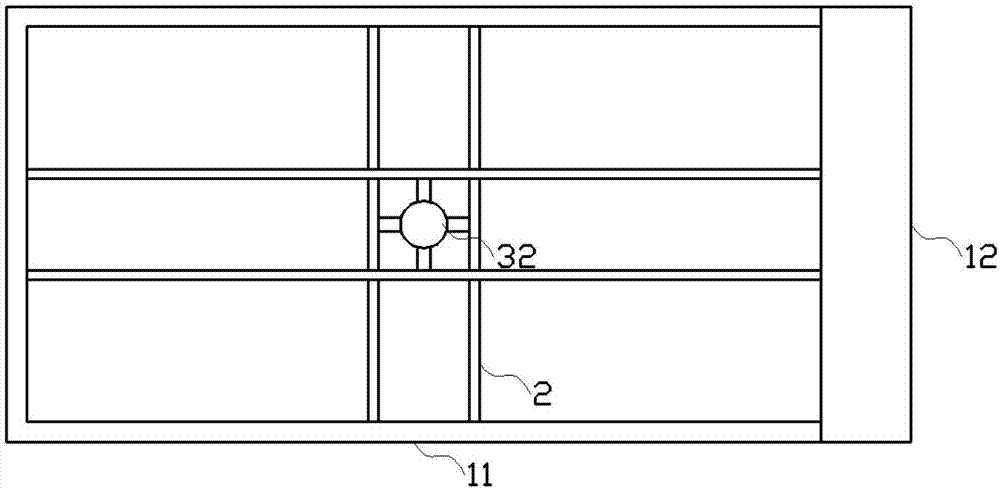

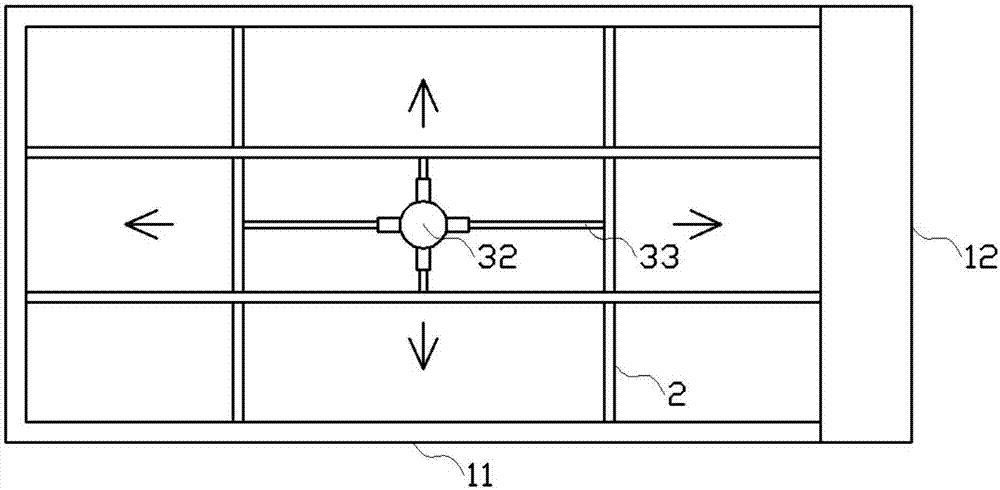

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown in the embodiment, the air column type automatic positioning wool trimming device is a device that can automatically position the sheep, facilitate the user to trim the wool, and at the same time accurately measure the weight of the trimmed wool. It includes There are a fence module 1, a positioning rod module 2 and a power module 3; the fence module 1 includes a shell 11 and a pedal 12; the side plate of the shell 11 is designed as a fence, and the bottom of the shell 11 is designed with a fixed plate, so The side plate of the housing 11 is vertically fixed on the fixing board, the interior of the fixing board is designed as a cavity, the side of the housing 11 is designed with an opening, and the opening is designed with a door opening device; the pedal 12 is designed It is in the shape of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com