Swing arm manipulator

A technology of a manipulator and a swing arm base, applied in the field of manipulators, can solve the problems of poor operating environment and rising labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

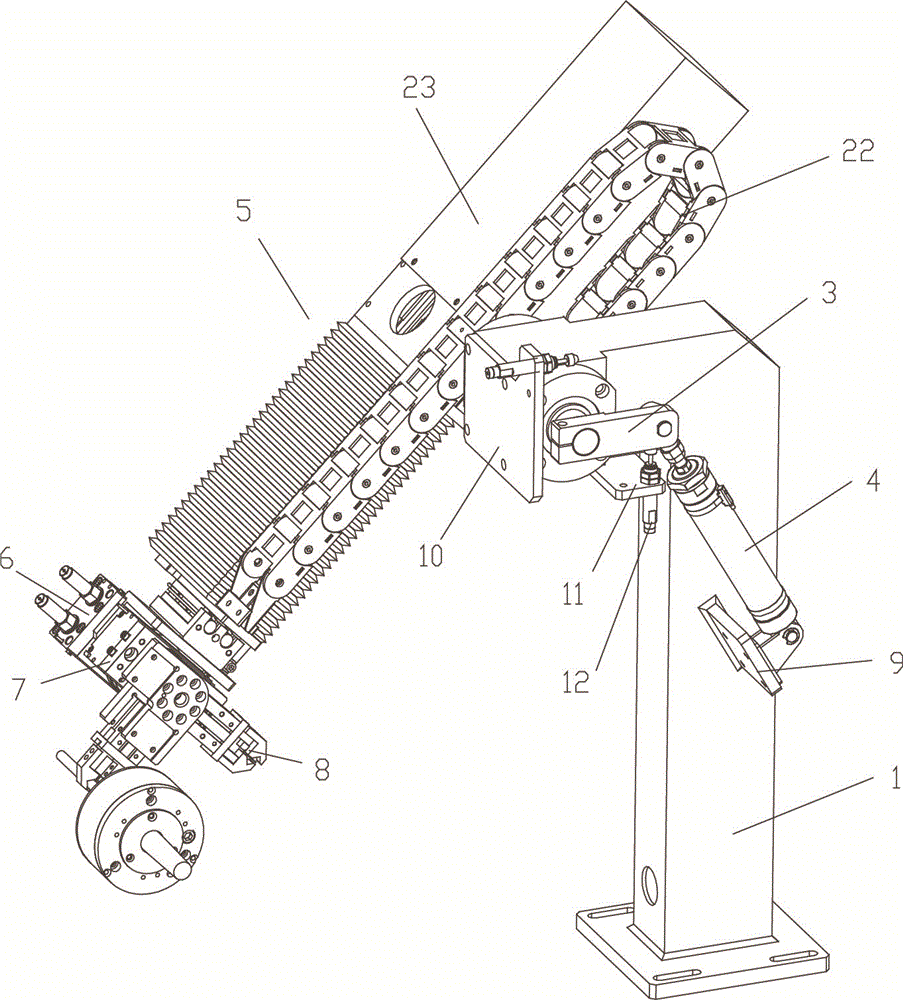

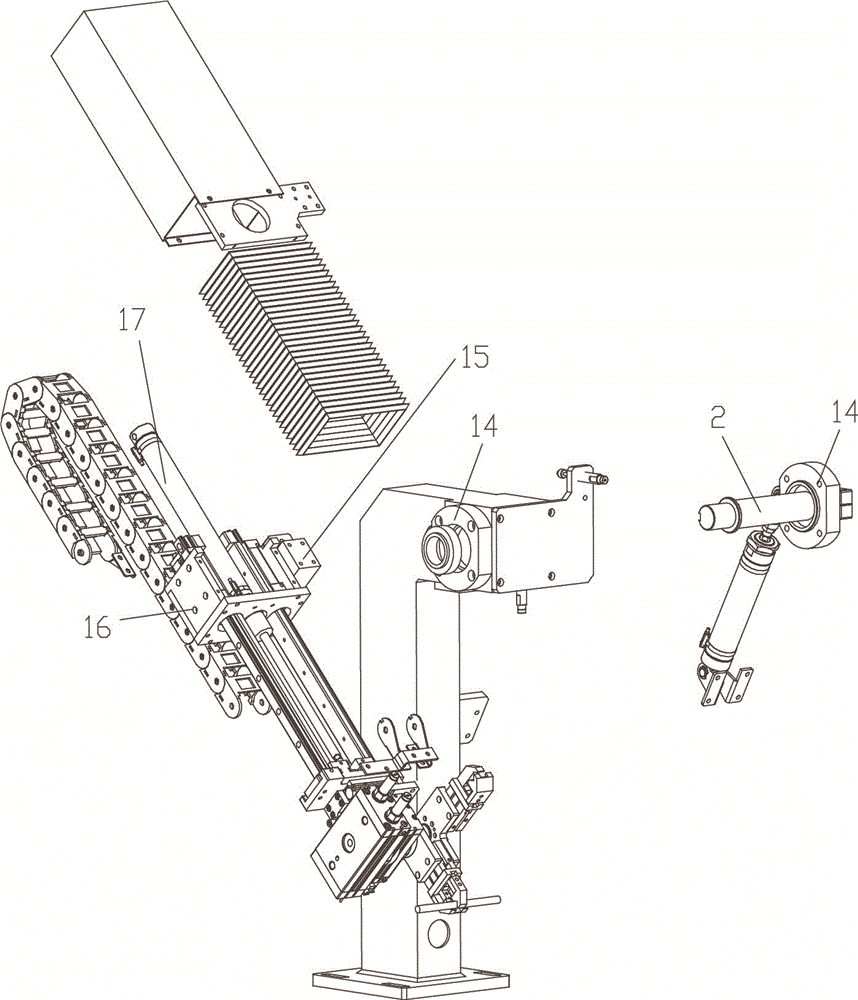

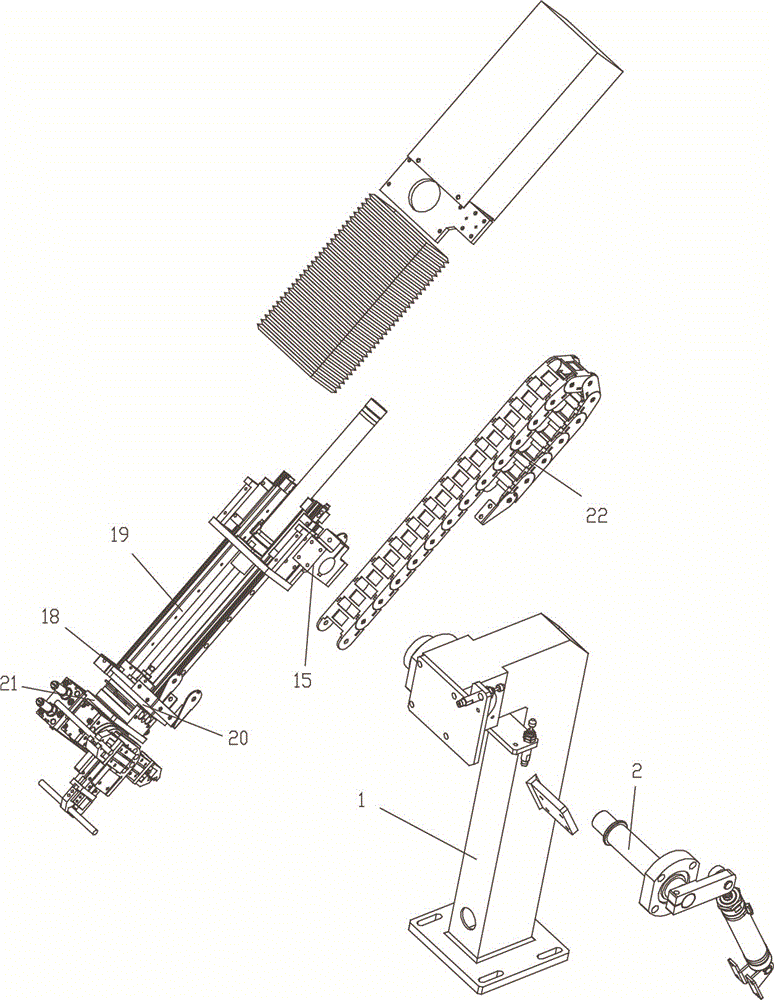

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1~3 As shown in the figure, the marks are as follows: column 1, rotating shaft 2, swing connecting rod 3, swing cylinder 4, swing arm mechanism 5, rotary cylinder 6, air claw cylinder 7, air claw 8, cylinder seat 9, vertical plate 10 , horizontal plate 11, oil pressure buffer 12, turntable bushing 14, connection block 15, swing arm seat 16, swing arm cylinder 17, cylinder top plate 18, linear guide rail 19, guide rail top plate 20, air claw connection block 21, drag chain 22. Cover body 23.

[0015] The swing arm manipulator includes an inverted L-shaped column 1. The upper end of the column 1 is provided with a rotating shaft 2. One end of the rotating shaft 2 is provided with a swing connecting rod 3 and a swing cylinder 4. The other end of the rotating shaft 2 is provided with a swing arm mechanism. 5. A rotating cylinder 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com