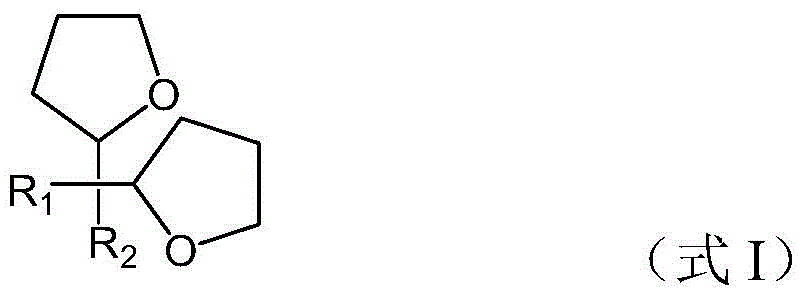

A structure regulator for anionic polymerization and an anionic polymerization method

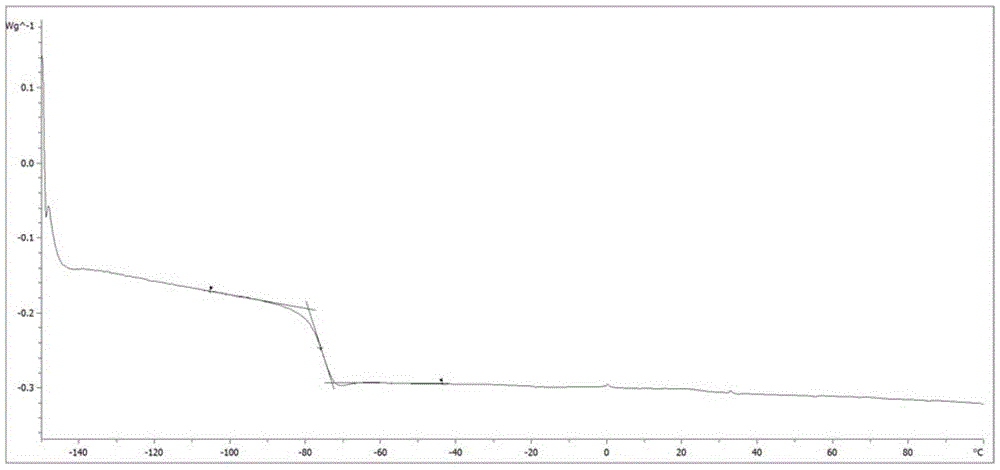

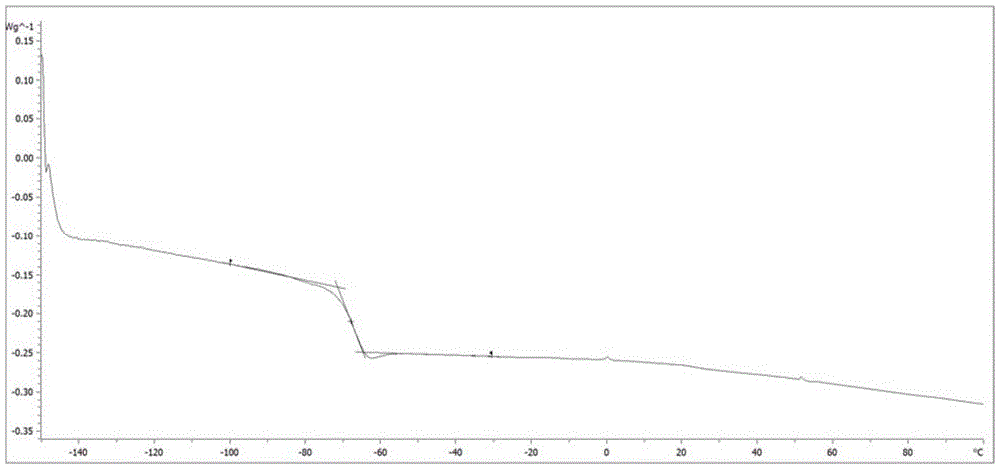

A structure regulator and anionic polymerization technology, applied in the field of anionic polymerization, can solve the problems of irritating odor, strong, safety and environmental protection, and achieve the effect of excellent low temperature resistance and low glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] In a 5-liter stainless steel stirred reactor, under the protection of high-purity nitrogen, add 2288g of mixed solvent (a mixture of cyclohexane and n-hexane, the mass ratio of cyclohexane / n-hexane is 82 / 18), 186g of isopentyl Diene and 186 g butadiene. Then, add 2,2-(ditetrahydrofuryl)propane and tetrahydrofurfuryl butyl ether, wherein, the amount of 2,2-(ditetrahydrofuryl)propane (DTHFP) is 0.69mmol, tetrahydrofurfuryl butyl ether The dosage of (BET) is 0.173mmol (DTHFP / Li=0.2, BET / Li=0.05). Next, after removing impurities with n-butyl lithium initiator, 3.45 mmol of n-butyl lithium was added to initiate polymerization. The polymerization reaction was carried out at a temperature of 70° C., during the polymerization reaction, the pressure was controlled at 0.1 MPa, and the polymerization reaction time was 40 minutes. After the polymerization was completed, 0.59 mmol of tin tetrachloride was added into the reactor, and after stirring for 70 minutes, 0.69 mmol of isop...

Embodiment 2

[0085] In a 5-liter stainless steel stirred reactor, under the protection of high-purity nitrogen, add 2288g of mixed solvent (a mixture of cyclohexane and raffinate, the mass ratio of cyclohexane / raffinate is 82 / 18), 178g Isoprene and 76 g butadiene. Then, add 2,2-(ditetrahydrofuryl)propane and tetrahydrofurfuryl butyl ether, wherein, the amount of 2,2-(ditetrahydrofuryl)propane (DTHFP) is 0.43mmol, tetrahydrofurfuryl butyl ether The dosage of (BET) is 0.43mmol (DTHFP / Li=0.1, BET / Li=0.1). Next, a n-butyllithium initiator was used to kill impurities, and 4.3 mmol of n-butyllithium was added to initiate polymerization. The polymerization reaction was carried out at a temperature of 40° C., during the polymerization reaction, the pressure was controlled at 0.2 MPa, and the polymerization reaction time was 40 minutes. After the polymerization was completed, 0.73 mmol of tin tetrachloride was added into the reactor, and after stirring for 70 minutes, 0.86 mmol of isopropanol was...

Embodiment 3

[0088] In a 5-liter stainless steel stirred reactor, under the protection of high-purity nitrogen, add 2288g of mixed solvent (a mixture of cyclohexane and n-pentane, the mass ratio of cyclohexane / n-pentane is 82 / 18), 187g Isoprene and 125 g butadiene. Then, add 2,2-(ditetrahydrofuryl)propane and tetrahydrofurfuryl butyl ether, wherein, the amount of 2,2-(ditetrahydrofuryl)propane (DTHFP) is 1.34mmol, tetrahydrofurfuryl butyl ether The dosage of (BET) is 0.19mmol (DTHFP / Li=0.7, BET / Li=0.1). Next, a n-butyllithium initiator was used to kill impurities, and then 1.92 mmol of n-butyllithium was added to initiate polymerization. The polymerization reaction was carried out at a temperature of 50° C., during the polymerization reaction, the pressure was controlled at 0.3 MPa, and the polymerization reaction time was 40 minutes. After the polymerization was completed, 0.326 mmol of tin tetrachloride was added into the reactor, and after stirring for 70 minutes, 0.384 mmol of isopro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com