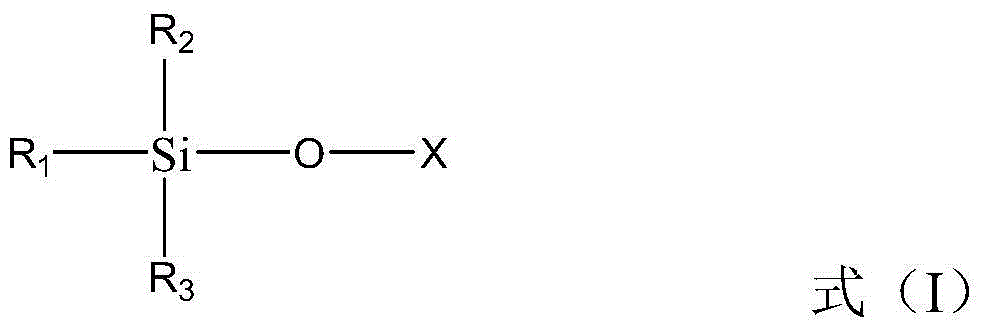

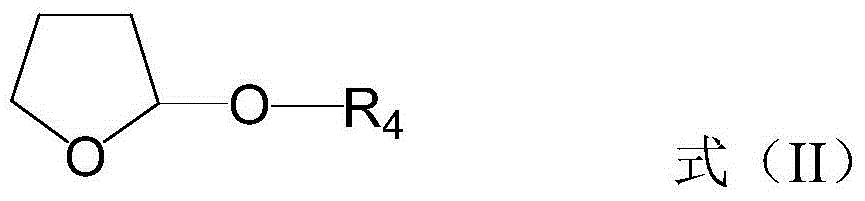

Structure regulator for anionic polymerization and anionic polymerization method

A structure regulator, anionic polymerization technology, applied in the field of anionic polymerization, can solve the problems of increased rolling resistance, increased tire heat generation, affecting the service life of tires, etc., and achieves the effect of low rolling resistance and reduced content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Before polymerization, the mixed solvent (cyclohexane and n-hexane, weight ratio 88:12) was soaked with 5A molecular sieves (φ3×5, purchased from Dalian Kangyu Chemical Co., Ltd., prebaked at 500°C for 5 hours) for 1 week. Under the protection of high-purity nitrogen, 195Kg of mixed solvent, 7.83Kg of styrene, and regulator Tetrahydrofurfuryl Ethyl Ether (ETE, purchased from Sinopharm Chemical Reagent Beijing Co., Ltd., the same below) 62.7 g and sodium dimethyl butyl siliconate (purchased from Sinopharm Chemical Reagent Beijing Co., Ltd., the same as below) 5.94g, after the polymerization system is deoxygenated by high-purity N2, add 21.17Kg of butadiene, stir for 10 minutes, add 350ml of n-butyllithium solution (the concentration of n-butyllithium is 0.6mol / L) was used for polymerization. The polymerization initiation temperature was 50° C., and the reaction pressure was 0.1 MPa. After 10 minutes of reaction, the peak temperature reached 90° C., and the reaction pre...

Embodiment 2

[0093] Before polymerization, the mixed solvent (cyclohexane and n-hexane, weight ratio 88:12) was soaked with 5A molecular sieves (φ3×5, purchased from Dalian Kangyu Chemical Co., Ltd., prebaked at 500°C for 5 hours) for 1 week. Under the protection of high-purity nitrogen, 195Kg of mixed solvent, 7.83Kg of styrene, 81.22g of regulator tetrahydrofurfuryl ethyl ether, and potassium dimethyl butyl siliconate (purchased from Sinopharm Chemical Reagent Beijing Co., Ltd., the same below) 5.78g, after the polymerization system was deoxidized by high-purity N2, 21.17Kg of butadiene was added, and after stirring for 10 minutes, 350ml of n-butyllithium solution was added (the concentration of n-butyllithium was 0.6 mol / L) for polymerization. The polymerization initiation temperature was 50° C., and the reaction pressure was 0.1 MPa. After 10 minutes of reaction, the peak temperature reached 90° C., and the reaction pressure was 0.28 MPa. After 10 minutes of peak temperature, add 17...

Embodiment 3

[0096] Carry out according to the method for embodiment 1, difference is regulator tetrahydrofurfuryl ethyl ether 50.78g and sodium dimethyl butyl siliconate 7.22g, the number average molecular weight of the obtained styrene-butadiene rubber, molecular weight distribution , The microstructure data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com